Testing research reveals Aluminium Matrix Composites (AMCs) can reduce weight and increase power density by up to 300%.

AMCs can radically improve the efficiency and responsiveness of hybrid and electric engines by increasing electric rotor strength and stiffness, improving power density by a factor of two to three, and reducing mass and inertia.

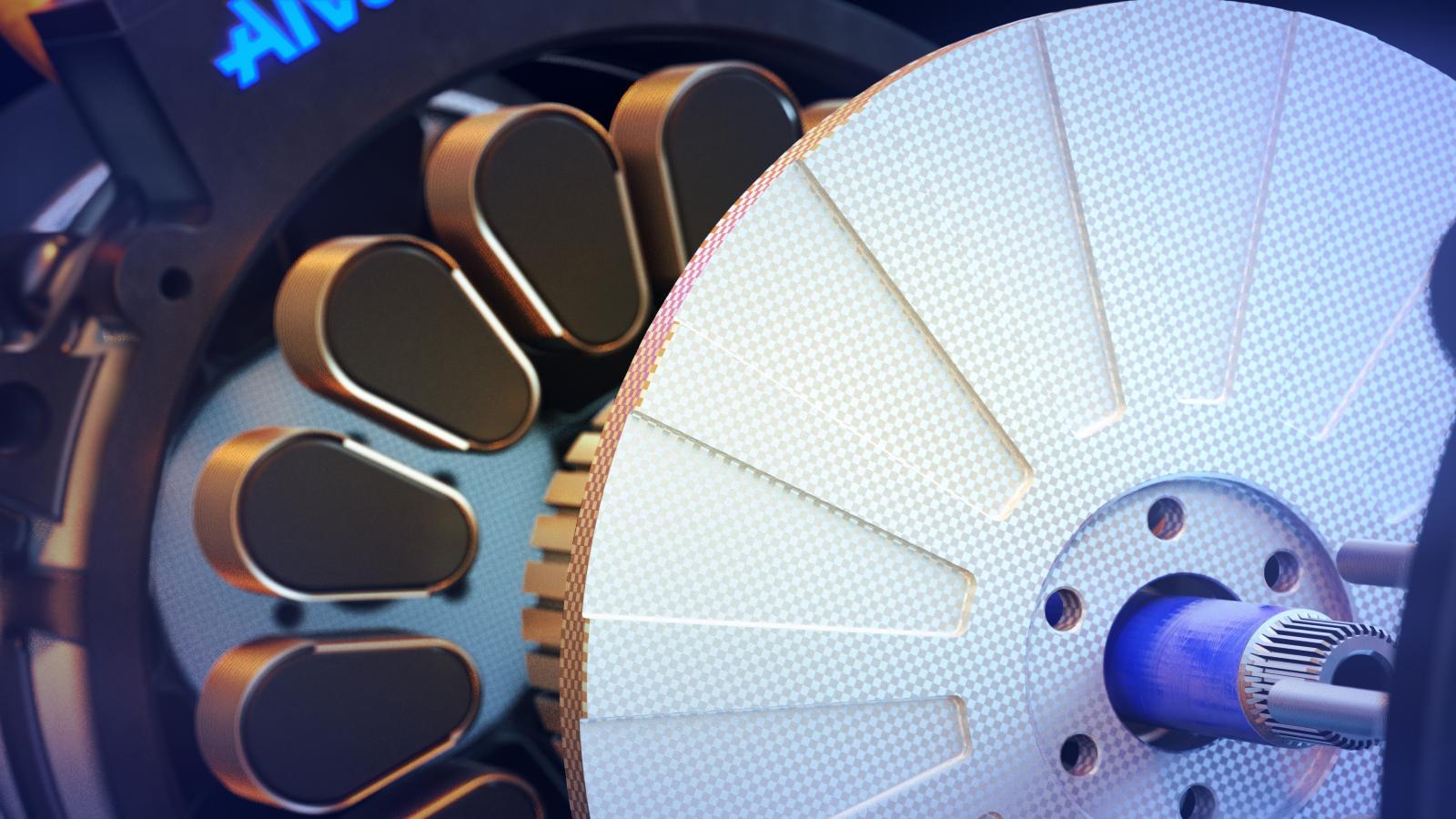

AMCs are an advanced class of composite materials in which the aluminium is reinforced with high-performance ceramics and are suitable for applications where conventional metals are expected to approach or exceed their performance limits.

Independent research commissioned by AMC manufacturer, Alvant, found that if the rotors in axial flux motors (AFMs) suitable for passenger cars were made from AMCs, rather than steel; mass and inertia would be reduced by 45 to 73 per cent, and overall motor weight by 19 to 25kg.

Weight saving

The precise extent of the weight savings depends on the type of axial flux motor. In AFMs with electrical steel cores, the weight saving would be 45 per cent per motor; in AFMs with soft magnetic cores the saving is 50 per cent; and in AFMs with a Halbach Array the saving is 73 per cent.

This weight reduction and ability to increase the rotor speed increases the power density, a holy grail of electric motor development, by a massive 225 to 300 percent. In the simulated tests, transient response was also seen to improve when typical torque available at 8,000 rpm was applied to the rotor. Due to the higher specific strength and stiffness of AMCs, speeds of 15,000 rpm would, according to Alvant, also be reliably sustainable.

Electric variants of combustion engine vehicles are typically ~125 per cent heavier, therefore there is a need to reduce weight in order to increase driving range from a single battery charge; For an average electric vehicle, a six per cent weight saving provides an additional 3km of range. As range is increased, the vehicle could also facilitate a smaller battery leading to a ~£300 reduction in battery production costs and ~£450 per annum reduction in ownership costs.

Tailored AMCs

AMCs can be precisely tailored for stiffness, strength, density, thermal properties, and electrical properties. It is also possible, by using Alvant’s unique Advanced Liquid Pressure Forming (ALPF) method, to selectively reinforce areas of a mechanical component with these high-performance materials in a near net shape manufacturing approach. Alternatively, Alvant’s materials can be cost-effectively applied as discrete inserts into a component where an array of similar inserts meets the performance requirements.

Alvant’s commercial director, Richard Thompson, commented: “These latest research findings are potentially good news for vehicle manufacturers who face the new engineering challenges posed by hybrid and electric engines. The research data also affirms that AMCs are a more suitable material than polymer composites for use in components in motor shafts, the drivetrain, fans, flywheels, energy recovery systems, and batteries.”

By releasing this new data, Alvant has confirmed the findings of the 2014 ‘Make it Lighter with Less’ R&D competition run by Innovate UK, part of the UK Research and Innovation (UKRI) funding agency. Research by Alvant in collaboration with GE Aviation, YASA Motors, and the National Composites Centre, established that AMCs can achieve a 40 per cent rotor weight saving on an axial flux electric motor suitable for passenger cars, significantly increasing the rotor’s potential power-to-inertia ratio and improving engine efficiency and responsiveness.

Beyond the automotive industry, Alvant believe AMCs also have great potential for other rotational components, such as wind turbines – where manufacturers looking for efficiency gains, rotational dynamics, and ways to lower the inertia of components.