Contract electronics manufacturer Jaltek has invested in a second flying probe test machine that will enhance its technical capacity and throughput.

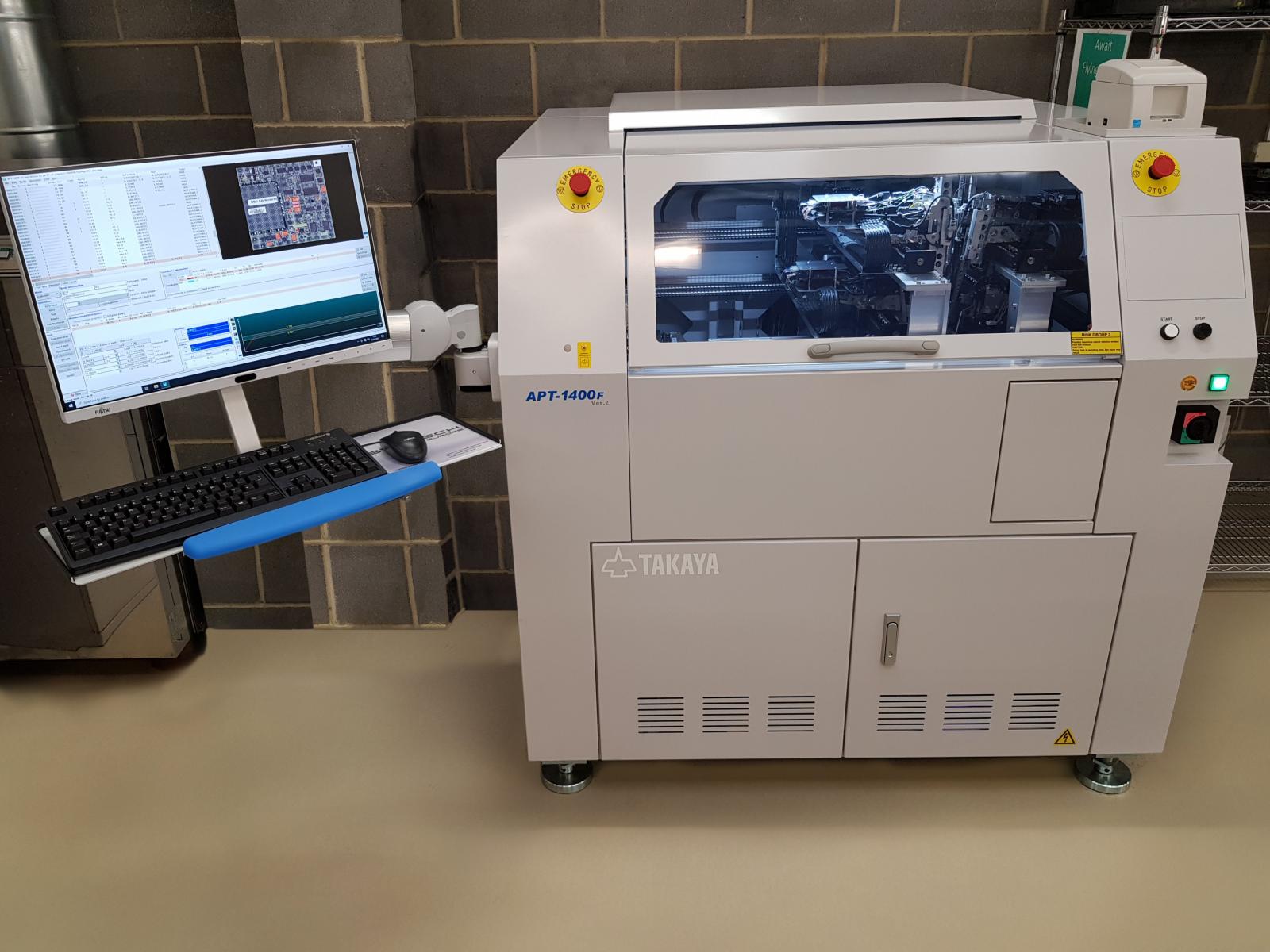

The TAKAYA APT-1400F is reported to be the fastest flying probe test system on the market, setting new standards for speed and test coverage, and will sit alongside Jaltek’s existing machine.

The system has been specially developed for the test of large quantities of complex circuit boards. The APT-1400F has 6 flying probes, of which 2 are vertical, enabling access to contact points that could not previously be reached. The design of the XY table has been completely revised and innovative test algorithms enable a significant increase in the test coverage on circuit boards.

The Takaya APT-1400F comes with a list of impressive features as standard, but Jaltek also installed a number of additional functions that it says makes its test speed, positioning accuracy and coverage unprecedented in the UK.

David Mills, the Takaya service and support manager for Accelonix UK, remarked: “I have over 25 years’ experience working with Takaya flying probes and know every installation in the UK, Jaltek’s new Takaya APT-1400F is the most fully featured model of its kind in the whole of the UK. Amongst all the usual refinements that many of our customers go for, Jaltek can also boast a number of additional features that will give even more value and flexibility to their customers.”

The additional features include a laser measuring unit that allows a single-sided tester to accurately measure component heights, to check for component compliance to IPC/customer requirements, BGS co-planarity to the PCB, or for non-fitted components.

Net Signal Wave Analysis (NSW) - heralded as a “quantum leap” in flying probe testing of PCBAs, characterises every net on a PCB into a unique signature which is used to compare against every board in the production batch. Most effective on large-scale densely populated PCBAs with many nets, NSW offers not only 100% shorts detection between every net on a PCB, but also it achieves this in a fraction of the time it would take conventional methods.

Commenting on the acquisition of this new Takaya machine Steve Pittom, Managing Director of Jaltek, said, ‘We continue our commitment to invest for our customers. This fully featured new flying probe will bring significant value to our customers particularly those who have AS9100 and ISO13485 requirements as well as for new product introduction. We can’t wait to start putting it to the test.’

Jaltek Systems is an AS9100 and ISO 13485 accredited UK contract electronics manufacturer with over 30 years’ experience. Focusing on low to medium volume, high mix product profiles for a range of industries, Jaltek’s services include conceptual design, PCBA layout, fast turnaround NPI, manufacture and test of PCBA’s and final product assembly.