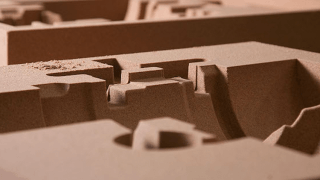

Sand casting is a very popular casting process, primarily because of the many benefits sand mouldings offer the casting process.

Key properties of a sand moulding

There are specific properties of sand moulds that have an important impact when we are creating quality castings. These include:

- Strength: Sand mouldings hold their shape under high stress

- Permeability: Sand allows gas and steam to escape during the casting process

- Flowability: Sand can fill small cavities and create a more precise mould

- Collapsibility: Sand allows the metal casting to shrink without the risk of cracking

- Refractory Strength: Sand can withstand extreme temperatures

- Controllable moisture content: Too little moisture in a mould may cause it to break apart. Too much moisture can cause steam bubbles

- Reusability: Sand can be reused for making new moulds

The benefits of using sand mouldings

The properties of a sand mould provide it with numerous and very specific benefits:

- Cost effective: Low tooling costs makes it one of the cheapest methods, making it ideally suited for lower volume needs.

- Offers wide material choice: As these moulds can withstand high temperatures they can be used with many different materials, including those with high melting temperatures.

- Quick to set up: This makes sand moulds great for prototyping and small production runs.

- Flexibility: Sand can be used to create moulds of many different sizes and with basic or complex shapes, making it useful for a large variety of designs.

- Quality surface texture: Using the right finish with these moulds can give an excellent surface texture.

- Minimal wear: Patterns used to create the mould can be reused many times with minimal wear during production.

- Environmentally friendly: Sand can be recycled to be reused which helps to ensure minimum waste and cost.

Haworth Castings

At Haworth Castings, based in Hampshire, our highly skilled engineers can produce high-precision aluminium sand and gravity-die castings for a wide variety of applications. Customers benefit from our cutting-edge technology and our wealth of design knowledge and experience.

Contact us today on 01794 512685 or email [email protected] to find out how we can support your casting needs.