CeramTec Group has produced ceramic sample containers for an Electro Magnetic Levitator used for experiments on the International Space Station.

In the course of this and previous joint product developments, CeramTec, together with Airbus Defence & Space and other partners in a project consortium, developed sample containers for experiments as complex components and manufactured them at the Plochingen site in Germany.

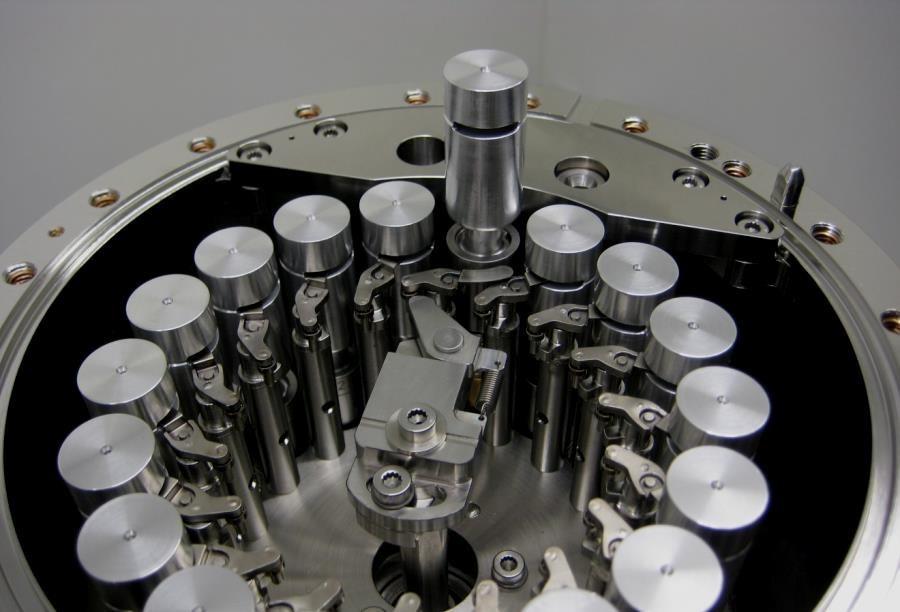

The latest pot sample holders and cage sample holders, which are made of silicon nitride, follow a previous lot of containers that were first installed in the International Space Station (ISS) back in 2017. They are used in the so-called Electro Magnetic Levitator (EML), a multi-purpose research facility for natural science experiments on board the ISS.

In the EML, the sample containers are inserted into a coil in which metal alloy samples are fixed all around in a contact-free manner by electromagnetic fields while suspended in zero gravity. For analysis, the samples are melted, cooled in the liquid state and then solidified again. These precision measurements of certain thermophysical properties of metals, alloys and semiconductors, which are not possible on Earth, make it possible to analyse the early phases of the formation of material structures and to expand our understanding of transition processes, atomic structures and material properties.

The objective here is to improve production and casting processes on Earth thanks to the material properties measured in space, in order to achieve an increase in quality while reducing the cost of high-tech castings (e.g., engine blocks).

This will allow manufacturing methods to be refined and materials and products to be improved and redeveloped. This basic research is being carried out by a collaboration between Airbus Defence & Space and the European Space Agency among others.

The ceramic material silicon nitride (Si3N4) is particularly suitable for this purpose due to its zero electrical conductivity, which prevents external influences on the measurements, as well as the required high heat resistance as the measurement cycles take place in temperature ranges between 500 and 2100°C.

The company says that these properties, in combination with the absolute reliability and consistently high product quality it can provide, have once again convinced the project consortium to use CeramTec advanced ceramics for what is perhaps one of the most demanding applications in the universe.

The sample containers of this latest generation started their journey into space with the SpaceX-22 in June 2021 and will significantly support further research activities there.

https://www.ceramtec-group.com/en/

Photo: The sample chamber with sample holders, copyright: Airbus