A custom measurement solution from Bowers Group has speeded inspection at Virtue Aerospace by 92%.

Bowers Group supported precision engineering company Virtue Aerospace with its compliance procedures using a bespoke measurement solution, supplied by Bowers Group distribution partner Mech Metrology, that has been designed to speed up the inspection process of aviation fuel pump impellers.

Based in Hampshire, Virtue Aerospace manufactures and oversees the balancing of pump impellers and inducers for the aerospace industry. Precision measurement forms a prerequisite to fulfilling stringent contract requirements for the business, therefore the need for accurate measurements is driven by the demands and expectations of its customers and the strict compliance requirements of the industries it serves.

To ensure the highest quality output, Virtue Aerospace asked Bowers Group to provide it with a bespoke measurement solution to assist in the delivery of parts that meet the tightest tolerances and the highest levels of accuracy and consistency.

Ian Smith, Quality & Environmental Manager at Virtue Aerospace, said: “The introduction of the measurement system from Bowers Group has reduced inspection time on a specific volume produced part, reducing the process time by a significant margin. The system is easy to set up, user-friendly and reliable, and we’re extremely impressed with the benefits it has brought to our workflow.”

The geometry of the fuel pump impellers is absolutely critical for fuel system as it impacts efficiency, flow, durability, and performance. A well-designed impeller enhances fuel delivery and reduces energy losses, as well as improving engine performance and reliability. It also affects noise, vibration, and maintenance costs. Finding the right balance between performance and manufacturability is essential.

Virtue Aerospace’s specific product had a 0.016mm total tolerance that requires 100% inspection to confirm compliance. The previous method of measurement was undertaken by a CMM machine and whilst the measurements were accurate, they were both time-consuming and costly.

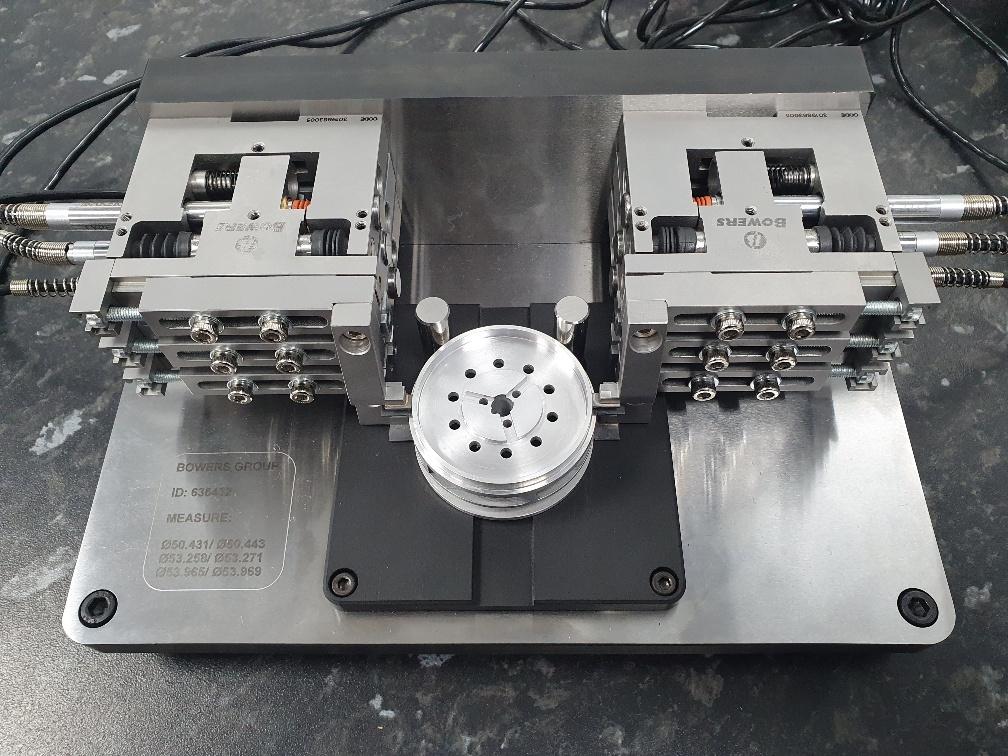

The solution that Bowers Group provided has transformed measurements by enabling the simultaneous assessment of three tight tolerance diameters, providing multiple benefits that enhance efficiency and productivity.

Since installing the system, inspection time for the part has significantly improved, falling from 180 seconds (3 minutes) carrying out the measurements on the CMM, to just 15 seconds with the newly implemented measurement system, resulting in an impressive 91.6% reduction in inspection time.

A key advantage is the straightforward setup of the system, featuring a user-friendly interface that reduces preparation time and maximises efficiency. Simultaneous measurements have helped reduce inspection time, and the system has been engineered for reliability, ensuring consistent and accurate results.