A custom-designed manufacturing cell at Irish subcontractor Lenane Precision aims to exploit the potential of automation on aerostructure components.

Designed and built by Mills CNC the turnkey automated cell will be installed at Lenane Precision’s facility in Smithstown, Shannon, County Clare in March 2020.

The cell represents a significant investment for Lenane and, when operational, will run 24/7 delivering significant productivity gains and process efficiency improvements to the company – substantially increasing its competitiveness.

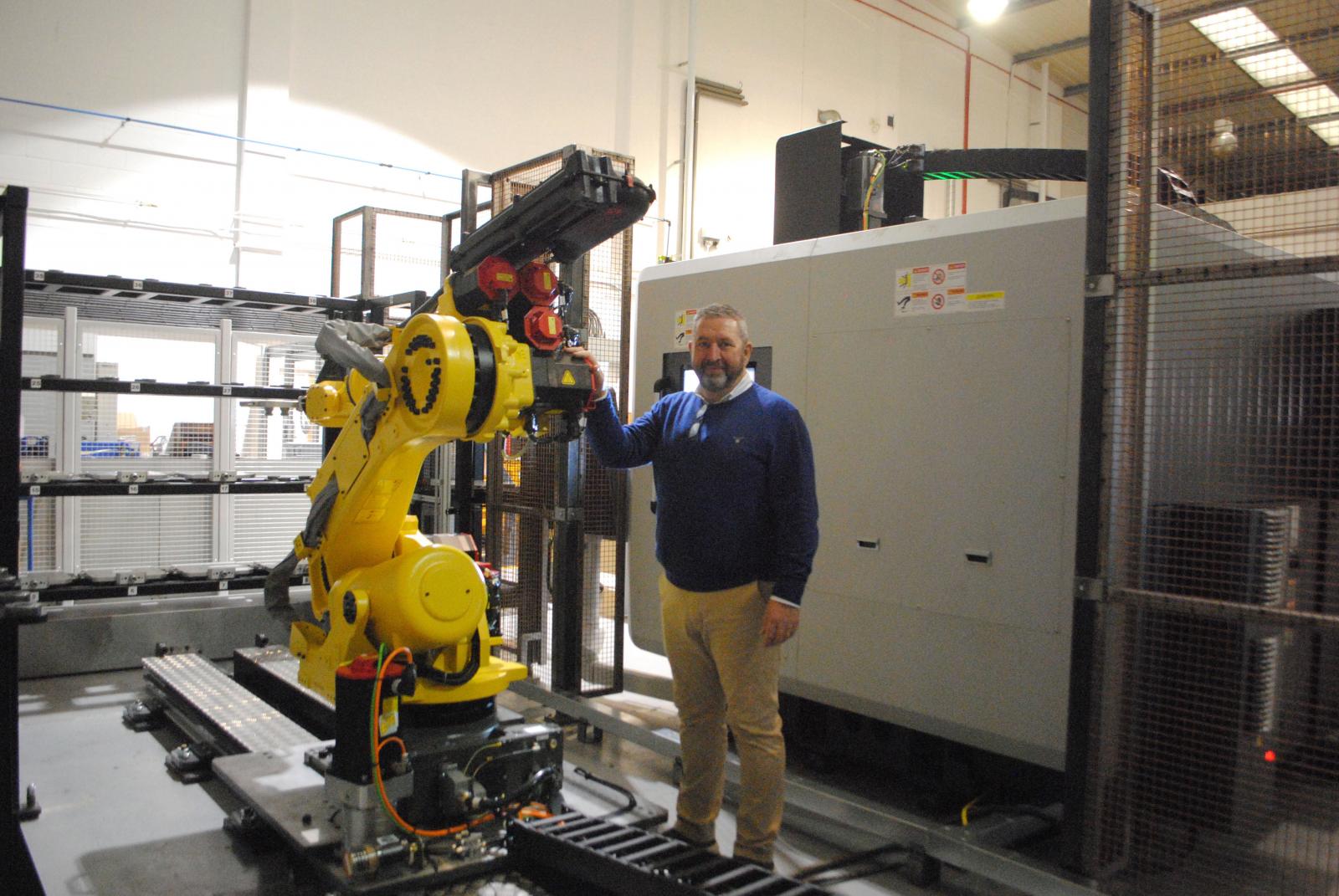

Based around two Siemens 840D-controlled Doosan DVF 5000 (5-axis) machines and a Fanuc industrial robot, the cell also incorporates at robot transfer track to allow the robot to load and unload both machines, an integrated 36-pallet racking system and a 2m high safety enclosure.

At the heart of the system is a sophisticated and powerful touchscreen HMI (Human Machine Interface) that uses Mills’ proprietary SYNERGi software to control the cell and that provides a seamless interface with the cell’s machine tools, robot etc.

Lenane serves a number sectors, but it is the company’s growing business in high precision aerostructure parts that has been the key driver for this project.

Jim Lenane, Managing Director, says: “The aerospace sector is global, challenging and demanding and, whilst success is never guaranteed, if you unable to meet the Industry’s exacting quality requirements, stringent lead-times and cost down demands you’re on a hiding to nothing”.

Lenane’s recent multi-axis, multi-tasking machine tool investments demonstrate its commitment to one-hit machining. For some companies the performance improvements gained from such investments may have been enough - but not for Jim Lenane.

“Continuous improvement is a journey not a destination”, he explains.

“My vision and ambition has always been to exploit the true potential of automation - the objective being to achieve continuous and seamless production in our facility, and to reduce, as far as is possible, the labour component from our machining processes.

“In reality I was waiting for the right time to realise the vision and, at the tail end of 2018 with orders from our existing aerospace customers reaching an all-time high and with firm commitments from them to place more orders with us in the future - the decision to put these plans into action was made.

“Integrated workpiece pallet changers were clearly an option for us but, from a continuous production perspective, this route had its limitations. I wanted something more ambitious - an automation solution that was future-proof.

“I knew that an automation solution that involved industrial robots was the direction of travel - so we set about exploring the options and alternatives.”

The critical prerequisites for the cell were that it should be flexible to allow expansion and new types of component, compact to meet Lenane’s floorspace constraints, and come from a single supplier.

Jim Lenane says: “We were looking for a turnkey solutions supplier to manage all aspects of the cell’s design and build. From an efficiency (and sanity) perspective it was important that we had a single point of contact for all communications relating to the cell and not have to manage relationships with the different equipment suppliers.”

Lenane approached a number of turnkey providers early in 2019 with their requirements and ultimately awarded the project to Mills CNC.

The cell, the first of its kind in Ireland, represents a completely bespoke automation solution and, needless to say, anticipation and expectation amongst Lenane’s 25 members of staff is high.

“A complex turnkey solution of this kind takes time to design and develop, and Mills CNC have pulled out all the stops to deliver something that is truly special.

“Our cell will soon be installed at our facility and we can’t wait to put it through its paces.”

BACK TO ENGINEERING CAPACITY NEWS PAGE