Scottish subcontractor NPI Solutions is using a collaborative robot to maximise machine uptime time and improve output on a 5-axis machining centre.

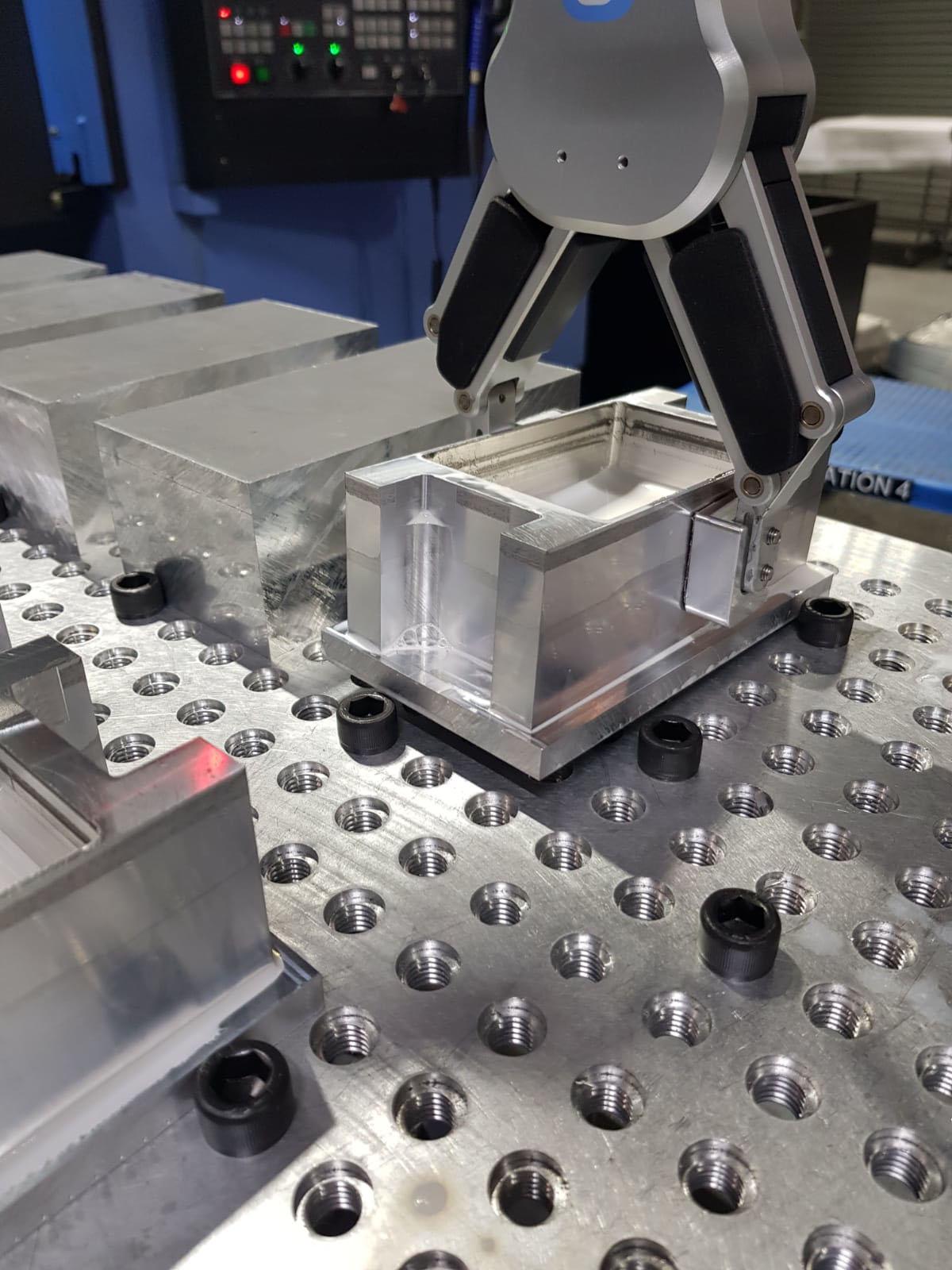

The Doosan M1013 cobot, which has a 1.3 metre reach radius and 10kg payload, is integrated with a Doosan DNM 350 5AX 5-axis machine that was installed in 2016. Both pieces of equipment were supplied by Mill CNC.

Since being installed the cobot has proved its worth by helping NPI optimise spindle up time, minimising operator interventions and dramatically improving the machine’s output.

NPI monitors and analyses the effectiveness and efficiency of its machines in order to allow it to identify and remove pinch points that affect productivity.

NPI’s managing director, Kevin Priestley said: “We invested in a Doosan 5-axis machine tool in 2016 to help make us more productive, efficient and competitive. The ability to machine precision parts in one set-up, via 3 + 2 and 4 + 1 machining was the appeal, and the goal.”

However, analysis of the machine’s performance over a period of time revealed that it was failing to deliver the expected results.

“It wasn’t the machine’s fault”, explains Kevin Priestley. “It was directly related to the type of production work we do which is characterised by low volumes and small batches, and by short part cycle times.”

This meant that the DNM 350 5AX could be idle for long periods each day to allow for frequent job set ups and changeovers to occur.

“Machines don’t make money if they are not making chips. To improve our profitability we needed to increase the DNM 350 5AX’s spindle up-time,” said Mr Priestley.

As a consequence the company began to explore automation as a route to improving the machine’s utilisation and output.

“There were a number of potential automation solutions available. We looked at automatic workpiece pallet change systems and industrial robots but their cost, floorspace requirements and complexity ruled them out.”

NPI required a more economically-viable and ‘simpler’ solution: one that could be quickly installed to transform the DNM 350 5AX into a flexible, automated manufacturing cell.

“We had investigated collaborative robot technology”, remembers Kevin Priestley. “The versatility of cobots in addition to their safety, their relatively lower investment cost and their ease of deployment were attractive propositions.”

Situated adjacent to the DNM 350 5AX which, as part of the installation was fitted with an automatic door opening/closing facility, the cobot is programmed to pick up blanks positioned on a peg table and load them, in turn, into the machine where they are machined to completion.

Once machining operations have been completed the cobot takes the finished (machined) component from the machine and places it back on the peg board in its predetermined position. This cycle is then repeated, with no operator intervention, until all the parts have been machined.

Cycle times can be as short as 2 minutes or up to 60 minutes depending on part size, complexity and features.

Says Kevin Priestley: “The ambition to create a flexible automated manufacturing cell has been realised through the cobot investment.

“During the day the cell is programmed to machine components with relatively short cycle times unattended allowing operators to work on other machines or perform other tasks.

“For parts with longer cycle times the cell is programmed to run attended overnight.”

NPI’s new cobot cell has helped dramatically improve its productivity, efficiency and competitiveness. The DNM 350 5AX is now running at 85% efficiency as opposed to just 50% efficiency prior to the cobot investment.