Cambridge Precision Ltd (CPL) has installed three new machining centres and a cobot to fulfil a new contract for high-end technical enclosures.

The Doosan machines, supplied by Mills CNC, were a DVF 5000 (5-axis) machine, a DNM 6700 vertical machining centre supplied with a Nikken 5-axis rotary table and a DNM 4500 vertical machining centre, along with a heavy-duty Doosan H2017 cobot.

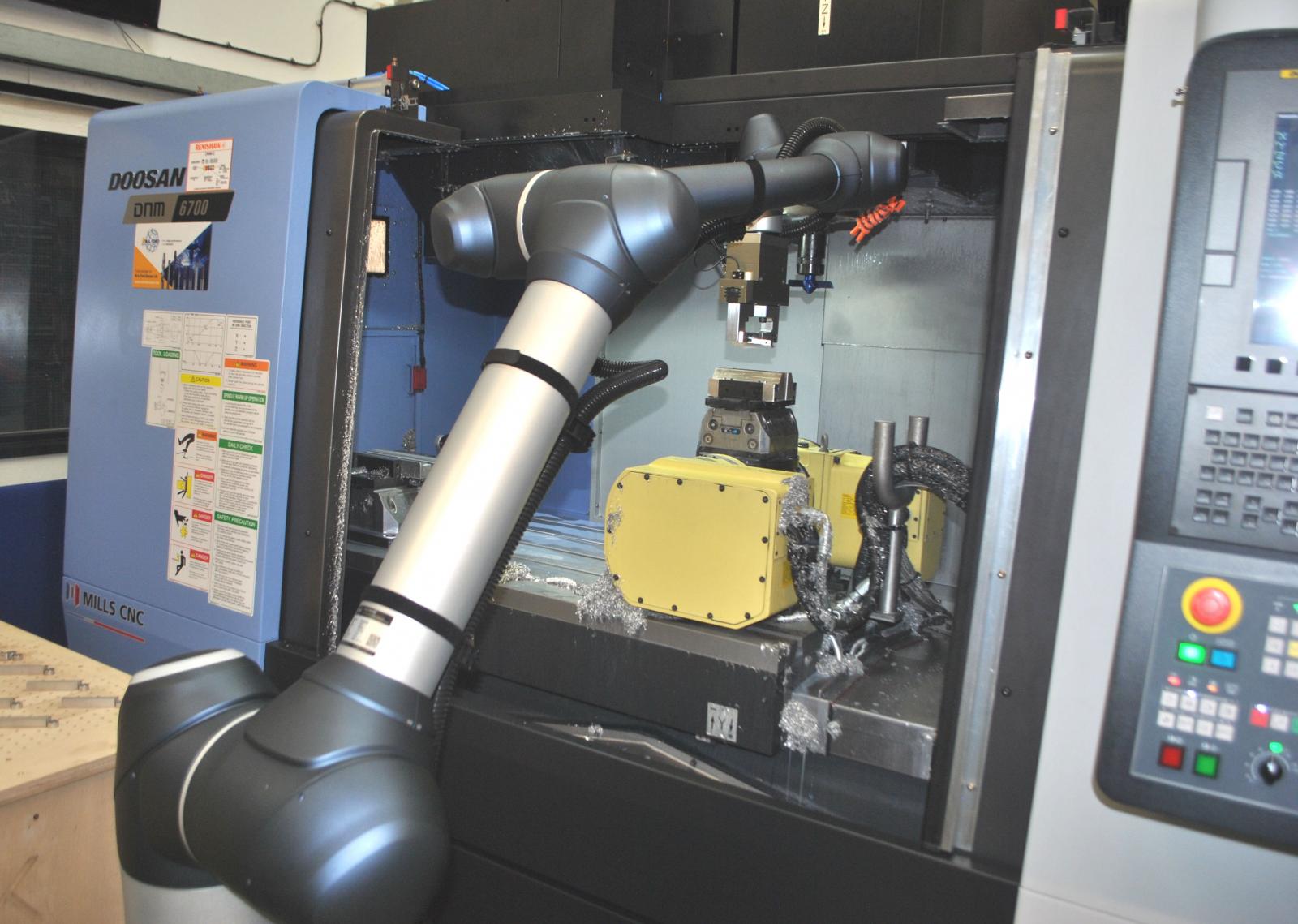

The cobot has been integrated with DNM 6700 machine to create flexible automated machining cell.

The new contract, from existing customer, called on the company to machine, in relatively high-volumes and to high-precision, a range of innovative and highly-stylised enclosures for a high-end technical product.

Alongside initial prototyping and pre-production work last year CPL audited its existing machining capacities to identify if, and where, any pinch points and bottlenecks could occur once in full production.

Says Nick Raven, CPL’s General Manager: “The audit revealed that we needed to significantly increase our milling capabilities and capacity in double quick time - and that a whole new dedicated machining resource would be required for the contract.

“Having scoped out the project in full taking into account volumes required, machining operations, part set-up and cycle times etc., we decided that a high-performance 5-axis machining centre, using its 5-side machining capabilities, would be ideal to machine the solid aluminium enclosures - and that a vertical machining centre integrated with a cobot plus another standalone machining centre would enable 24/7 continuous production.”

Andrew Barnard, CPL’s Milling Supervisor, added: “The H2017 cobot is the second Doosan cobot we have invested in over the last 18 months: the first being the smaller and more lightweight M0617 cobot that we acquired in July 2019.”

“The cobot, and the DNM 6700, are programmed to operate unattended during the day, overnight, and over the weekends too. Billets awaiting machining are positioned on the table 24 at a time, and cycle time per part is between 45 and 60 minutes, depending on the required features and details.

“Cobot help free-up skilled labour by handling repetitive and less profitable tasks. Rodney (our first cobot) and Derek (the recent arrival) have been welcomed by the team, and the arrival of both has enabled team members to focus on other manufacturing and assembly tasks whilst also ensuring accuracy and allowing us to plan machine operation times accurately.”

The expanded cobot-enabled machining centre is now tested and ready for full production, with consideration being given to further expansion.

The company is now actively looking to acquire new premises and is also looking to invest in more advanced machine tool technologies as customers continue to ramp up their production demands.

Nick Raven concludes: “We, like the UK economy in general, have bounced back strongly. The high-performance multi-axis and multi-tasking machine tools we have at our disposal, combined with the skill and dedication of our staff and the robust systems and processes we have in place have all helped us capitalise on the upturn.”