State-of-the-art connected metrology systems from Renishaw will be critical to the machining and inspection capabilities of the Digital Manufacturing Centre (DMC).

The DMC is further expanding its partnership with manufacturing technology leader Renishaw and says the new agreement is critical to the DMC’s on-site machining capability, which is delivered by precision engineering specialist Produmax.

The partnership will see Produmax’s machining and inspection services linked into the DMC’s intelligent, connected process chain. This will be a key element in the realisation of a true ‘digital twin’ and the real-world application of Industry 4.0 principles. Thanks to Renishaw, Produmax’s connected metrology solutions will significantly enhance the DMC’s efficiency and ability to deliver exceptional parts for the most demanding sectors.

Equipped with a new DMG Mori DMU 60 eVo linear 5-axis mill, Produmax will utilise a Renishaw OMP600 high-accuracy optical probe in conjunction with NC-Checker and NC-PerfectPart software from Renishaw associate company, MSP, to ensure machine capability and enable complex part alignment prior to machining. A Siemens controller will then be used to proactively adapt machining processes to the subtle variations in net-shape components made through additive manufacturing.

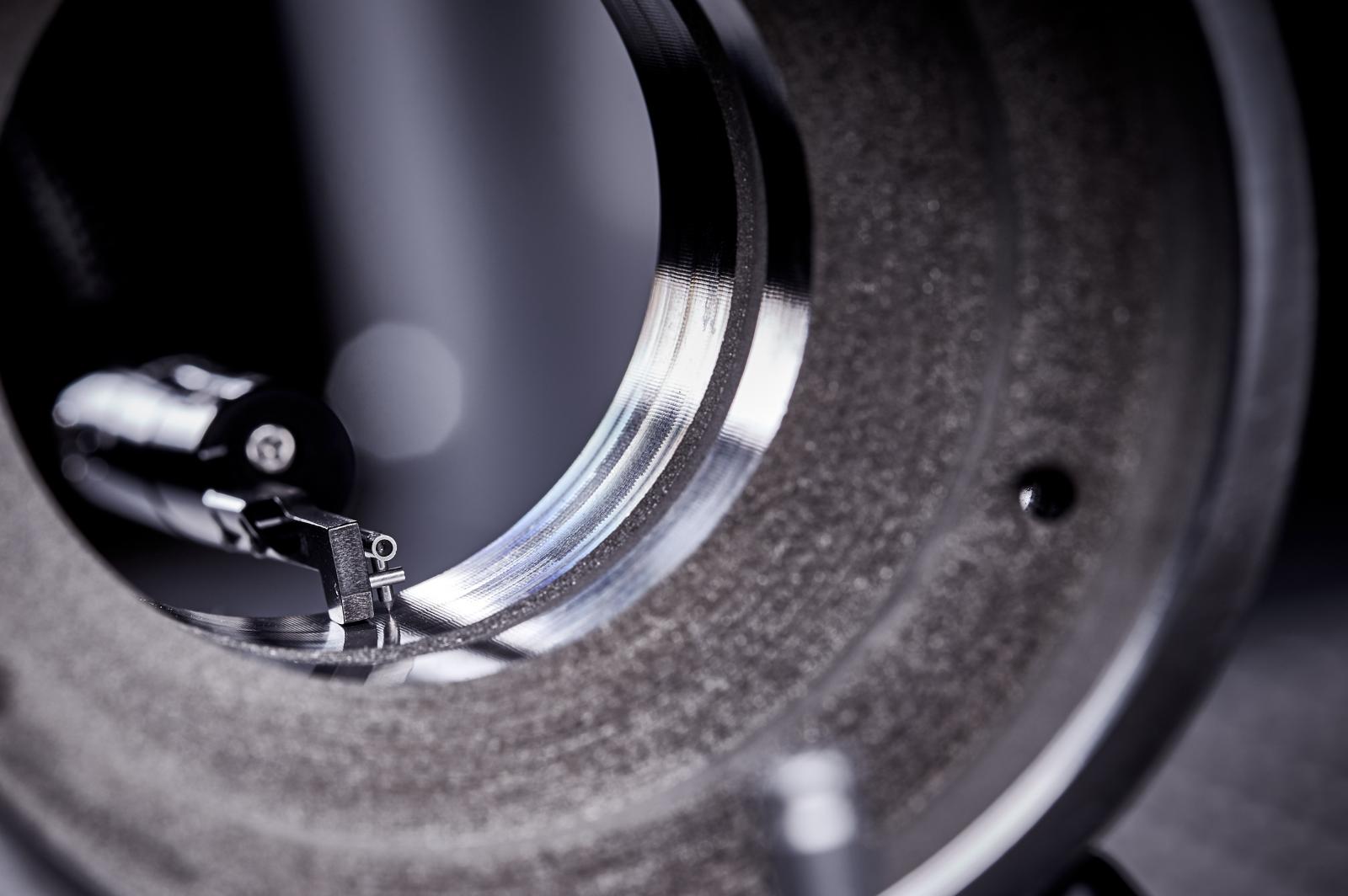

During machining, a Renishaw NC4+ Blue laser tool setter will be used to achieve the high levels of precision required to deliver the tolerances and surface finishes required by DMC customers. Produmax will then comprehensively analyse the parts using a versatile Renishaw REVO 5-axis measurement system to certify quality.

The REVO’s multi-sensor capability and high-performance scanning provide Produmax with non-contact and surface finish analysis in a single Coordinate Measuring Machine (CMM). It will come equipped with Renishaw’s 5-axis tactile scanning and touch trigger probe, surface finish measurement tools (SFP2) and non-contact optical Fringe Probe (RFP). This will give the DMC and Produmax the ability to carry out a variety of measurement tasks in one single datum system and in one operation.

Jeremy Ridyard, Managing Director at Produmax, commented: “Metrology is an essential aspect of delivering industry-leading machining, finishing and inspection services. Thanks to the support of Renishaw, we are bringing world-class metrology capabilities to the DMC, allowing us to digitally connect the entire process chain.

“This new agreement will enable us to link all the steps, each providing data to inform subsequent operations. Through digital connectivity and our well-established Quality Management Systems, the DMC will confidently deliver on the requirements of a wide variety of sectors, from aerospace to industrial.”

Kieron Salter, Chief Executive Officer at the DMC, concluded: “We are thrilled to have Renishaw play such a central role in enabling critical elements of the DMC. Together, alongside Produmax, we are realising the potential of connected additive and subtractive manufacturing. The addition of connected metrology is yet another demonstration of our ambition to level up UK manufacturing and establish ourselves as a world leader in advanced manufacturing.”