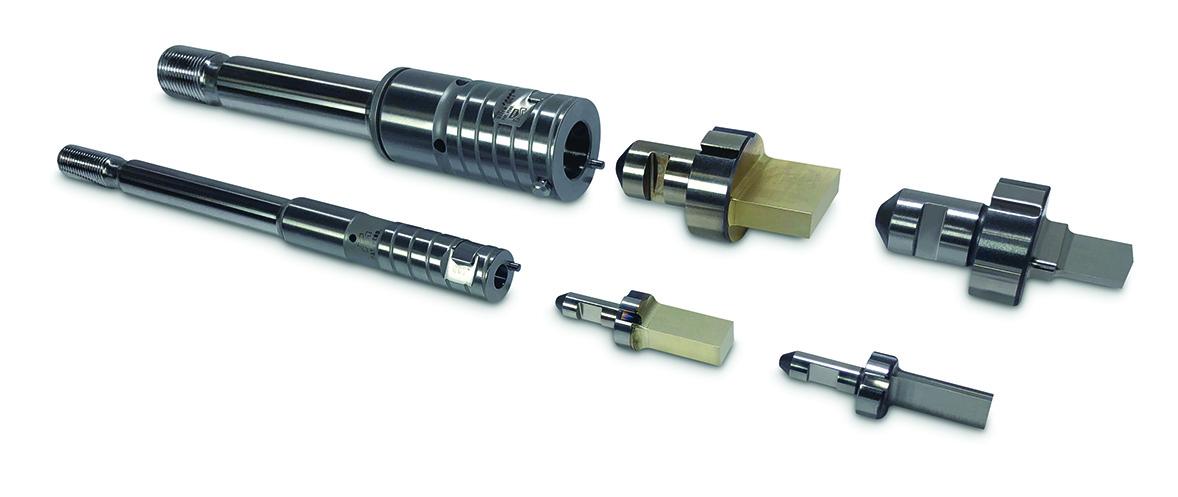

Sponsored story: Mate has introduced QCT Metric™ A & B Station Punch Drivers to its Ultra® QCT Quick Change, tool-less thick turret punching system.

These long stem punches are also known as Mate Original Style or Amada Style.

Designed for easier, faster setups, these new A & B Station punch drivers use Mate’s proven QCT™ punch retention system. It’s simple and intuitive. Also, QCT Metric A & B Station Punch Drivers simplify tooling inventory. These universal drivers may be used on rounds or shapes.

QCT Punch Inserts are made from Mate’s M4PM™ steel, the longest lasting tool steel in the industry. They are keyed at the perimeter for improved angularity control and have a .770 inch (19,56) SBR* for added grind life. When punching, the shoulder of the punch remains securely guided.

Adding to long-lasting performance, the driver portion (below the stem) is made from high speed steel. And it comes standard with Mate’s proprietary next generation SuperMax™ coating for extended life. This robust design has been proven in extensive tests with competitive tooling.

The compatible and “future proof” Ultra QCT Metric A & B station design is fully compatible with:

• Mate’s Ultra® family of guides and standard canisters.

• Mate’s Original Style guides and Rapidset™ canisters.

• Mate’s Original Style guides and spring packs.

• Fully interchangeable with Amada NCT, NEX and Z-Tooling systems as well as Wilson thick turret metric punches.

From a cost/value perspective, Mate’s QCT Metric A & B Station punch drivers have an overall lower price because of their design and manufacture with premium, longer-lasting materials.

For more information about Ultra QCT tooling and Mate’s complete line of punch press tooling, press brake tooling and laser consumables phone: 01604 630 646.

www.matetoolingsolutions.co.uk

*SBR is an industry term used to describe the grind life calculation