Orbital Fabrications (Stand C68) specialises in manufacturing high purity stainless steel manifolds and control systems for use in the semiconductor, pharmaceutical, chemical and process industries.

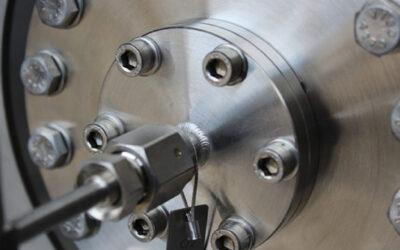

At Subcon 2021, Orbital Fabrications will be showcasing its latest developments and innovations in TIG welding techniques for fabricating complex assemblies in stainless and high nickel content alloys; utilising both automated orbital welding techniques alongside lathe and turntable TIG welding. This is supported by recent investment and expansion of its in-house CNC machine shop, giving greater control and management of the entire fabrication process.

The team will be available at booth C68 to discuss the latest innovations and support services on offer from Orbital Fabrications; starting from comprehensive in house design team services, through to test and qualification processes including in-house helium mass spectrometry for leak detection, alongside high pressure testing capabilities up to 400 bar.

For ultra-high purity applications, all fabrication, assembly and test is conducted within class 5 and class 6 cleanroom facilities, ensuring the highest levels of cleanliness, and ready for integration in the customers’ cleanroom facilities.

On display will be some examples highlighting these latest innovations in welding techniques and fabrication of fluid handling solutions for a wide range of industries and processes, and the Orbital Fabrications team will be pleased to walk you through these solutions.