Vestatec’s longstanding relationship with photochemical etching specialist Precision Micro is key to supplying speaker grilles to many of the world’s most luxurious vehicles.

The Nottingham-based company supplies unique styling solutions for premium brands like Bentley, Porche and Lamborghini.

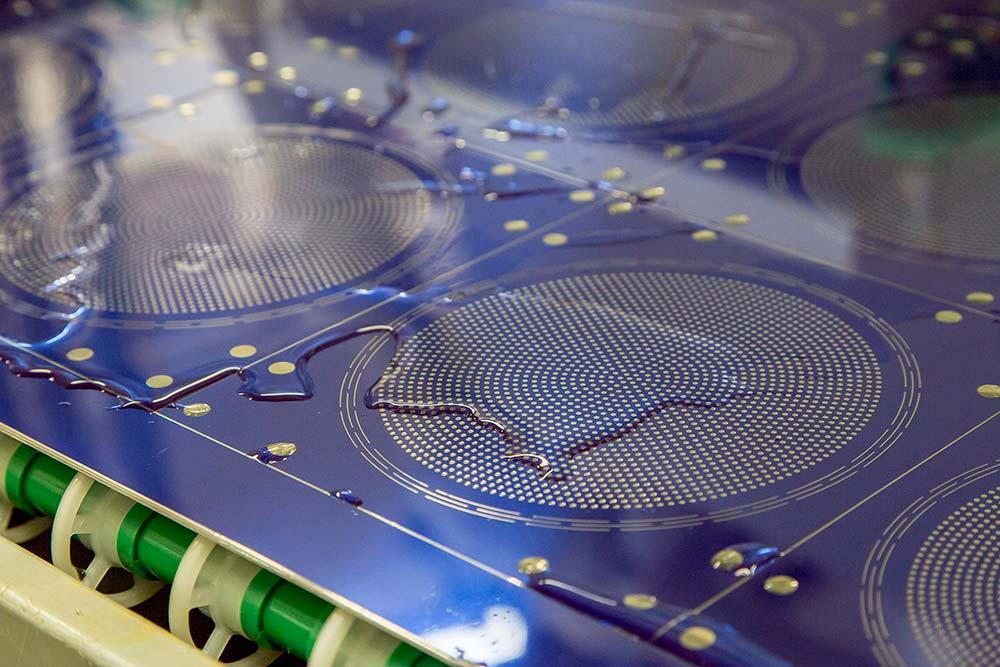

Photochemical etching allows Vestatec to bring intricate designs to life while also adding clear cost-saving benefits. Chemical etching also means that finished metal speaker grilles maintain their sleek appearance and tactile perception for longer, as well as offering improved sound quality and durability.

An alternative to traditional stamping and laser cutting, photochemical etching uses chemical etchants to create complex but highly accurate precision components from almost any metal. With hundreds of holes to cut in the average speaker grille, and the need for consistent, pinpoint accuracy, laser cutting is simply not viable.

Vestatec’s journey with Birmingham-based Precision Micro began a decade ago but Vestatec did offshore its supply briefly while Precision Micro was actioning a £5.1m recovery plan following a fire in 2019.

While Precision was back to full manufacturing potential within three months, reconfiguring its processes and increasing its overall capacity, Vestatec was facing difficulty importing product from the continent due to Brexit and the impact of the pandemic.

Precision’s rapid recovery, combined with importing woes, soon gave Vestatec the confidence to switch back to using Precision Micro as its primary supplier. Another key reason for the switch was Precision Micro’s product quality and service offering, while the geographical proximity of the two Midlands-based businesses presents significant benefits for prototyping and makes complex designs more feasible.

In automotive, continuous innovation and strong collaboration is key. Improving the driving experience requires creative thinking throughout the supply chain – something which Vestatec’s Adam Jay believes Precision Micro always helps to deliver.

“We really push Precision Micro to explore the limits of what's possible because ultimately, that’s how you innovate. We’ve often sent them designs which are theoretically impossible to manufacture but they always give their best efforts to make them a reality. This desire to go beyond what’s possible has helped us deliver some truly unique products,” said Adam.

Precision Micro’s value proposition ‘etching enhanced’ is something, by Vestatec’s own admission, that perfectly describes the business’s ability to explore the limits of its technology.

Adam Jay continued: “The etching process is high quality and it’s efficient for many reasons. Pushing boundaries and working collaboratively together stack up to provide USPs for both of us and I think the customers we deal with recognise our efforts to innovate and deliver consistent quality.”

BACK TO ENGINEERING CAPACITY NEWS PAGE