Phil Simmonds of EC Electronics says that when designing new mechanical products a holistic approach is the best option.

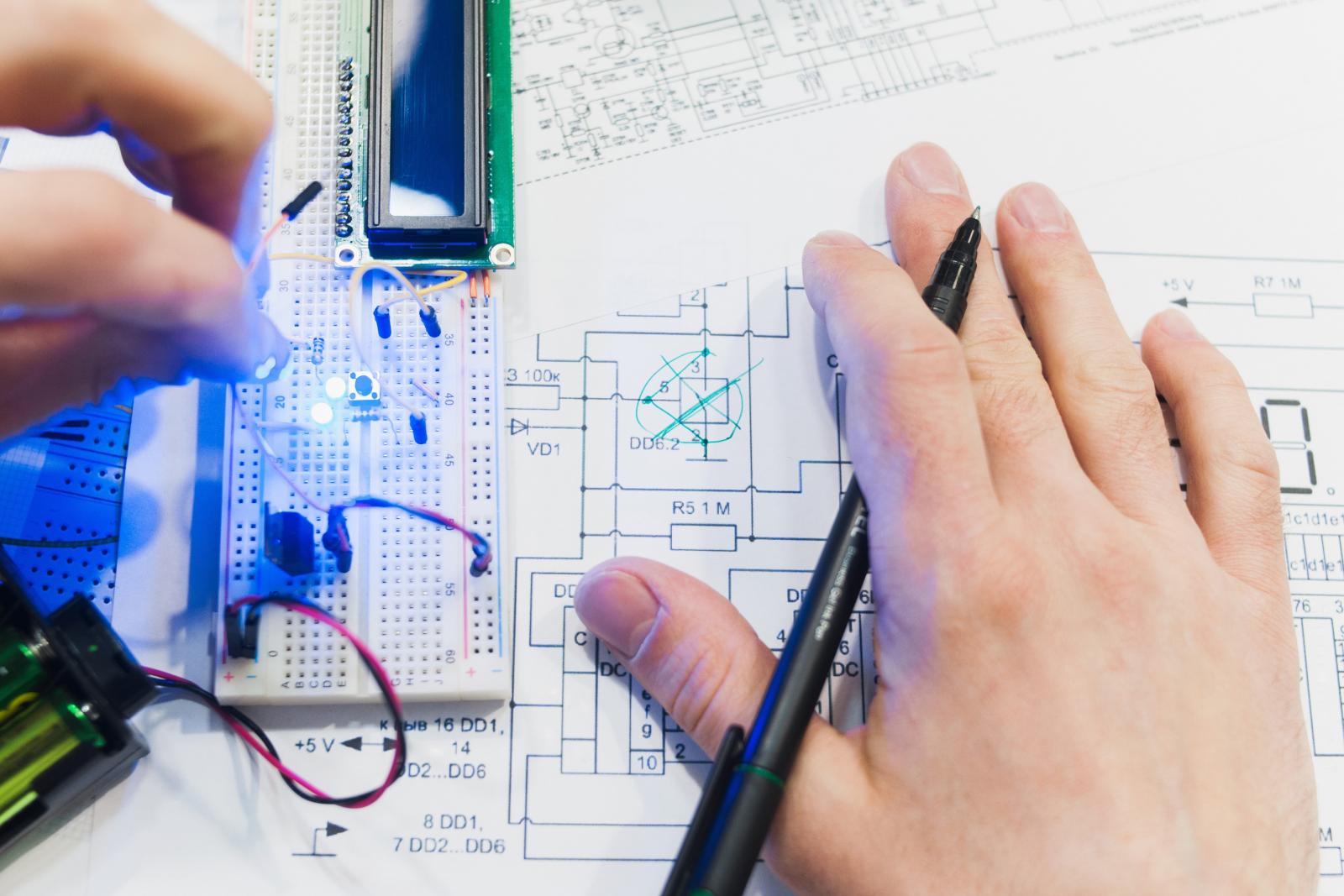

When electronics and mechanics meet we get mechatronics. A great example of this is your car – electronics drive the mechanics within most modern vehicles. Similarly, robots are clearly mechatronic systems; microcontrollers and PCBs control their mechanical functionality.

Look around at your office or home and you’ll find many more examples of mechanics and electronics working together to create new and inventive technology. From your digital thermostat, through Nike’s Self-Lacing Trainer (Nike HyperAdapt 1.0), to sensor augmented insulin pumps, which measure glucose levels at regular intervals and deliver insulin as needed; there are numerous examples of mechatronic systems.

Mechatronics and The Internet of Things (IoT)

A major area where mechanics and electronics are working together is in IoT. The Internet of Things requires that each engineering group – mechanical and electrical – work together rather than in silos. Traditionally, mechanics would work on enabling the physical motion of a product, bearings, drive mechanisms, rails etc. Whereas electrical would focus on power, sensors, controllers and more.

With mechatronics and IoT these two disciplines have become more integrated, technology is shared and there are cost savings to be had too. An example of this is in smart motor technology. Smart motors are changing motion system design, taking over functions – including data acquisition and control, network communications, diagnostics, and protection – that once involved different systems and components.

The result of this collaboration between electronics and mechanics can be measured in various ways. The following points demonstrate some of the key benefits of giving equal weight to electronics and mechanics when approaching product realisation:

Enhanced functionality

Typically products that are based on a mechanical design only have one function. For example, a mechanical thermostat can only be programmed to heat a room to one temperature between certain times of the day. Whereas a digital thermostat allows the user to select different temperatures at different times of the day. Incorporating a microcontroller into a product opens up more features and functionality.

More user-friendly

These additional functions also make the product more user-friendly. Users have more options to tailor the product to their needs. Whether that is programmability, or convenience factors such as LED displays and safety features.

Smaller size

Solutions using electronics can help reduce the size of a product and deliver benefits for users and manufacturers. In fact, with advances in micro-electronics, many mechanical functions can be replaced with much smaller components and systems.

More intelligent

Intelligent electronic solutions can also have a positive impact on costs and efficiency. For example, a microcontroller can ensure that energy is delivered to only the parts of the system that need it, shutting down other areas when not in use. This can help improve efficiency as well as deliver energy savings, such as better battery life.

Improved safety

Mechanical products can also be made safer when electronics are incorporated. Numerous safety checks can be easily added to a system to ensure that it is operating correctly. Smart sensors can improve machine performance, reduce downtime and implement maintenance when necessary. They can also shutdown machinery if certain parameters are met; sensing temperature, humidity and other factors that might have safety implications.

When designing new mechanical products, or looking at ways to modify or improve existing solutions, EC Electronics recommend that you take a holistic approach to mechanics and electronics. Partner with suppliers with product realisation services and expertise, as they can often help deliver cost savings and drive efficiencies right from the start of a project.