Rockwood Composites has increased its workforce by 50% and is building two new 100 tonne presses to meet growing aerospace demand.

Mark Crouchen, Managing Director of Rockwood Composites, said: “By increasing our workforce and our capacity we can ensure a continuing supply of complex, bespoke components to our customers and maintain the highest possible level of customer service.

“The composites industry, particularly the aerospace sector, is experiencing rapid growth, and we are seeing this with more enquiries and more orders. We consistently reinvest in Rockwood to ensure we continue to supply our customers with dedicated engineering support so that they can fully benefit from the unique advantages of compression and bladder moulding.”

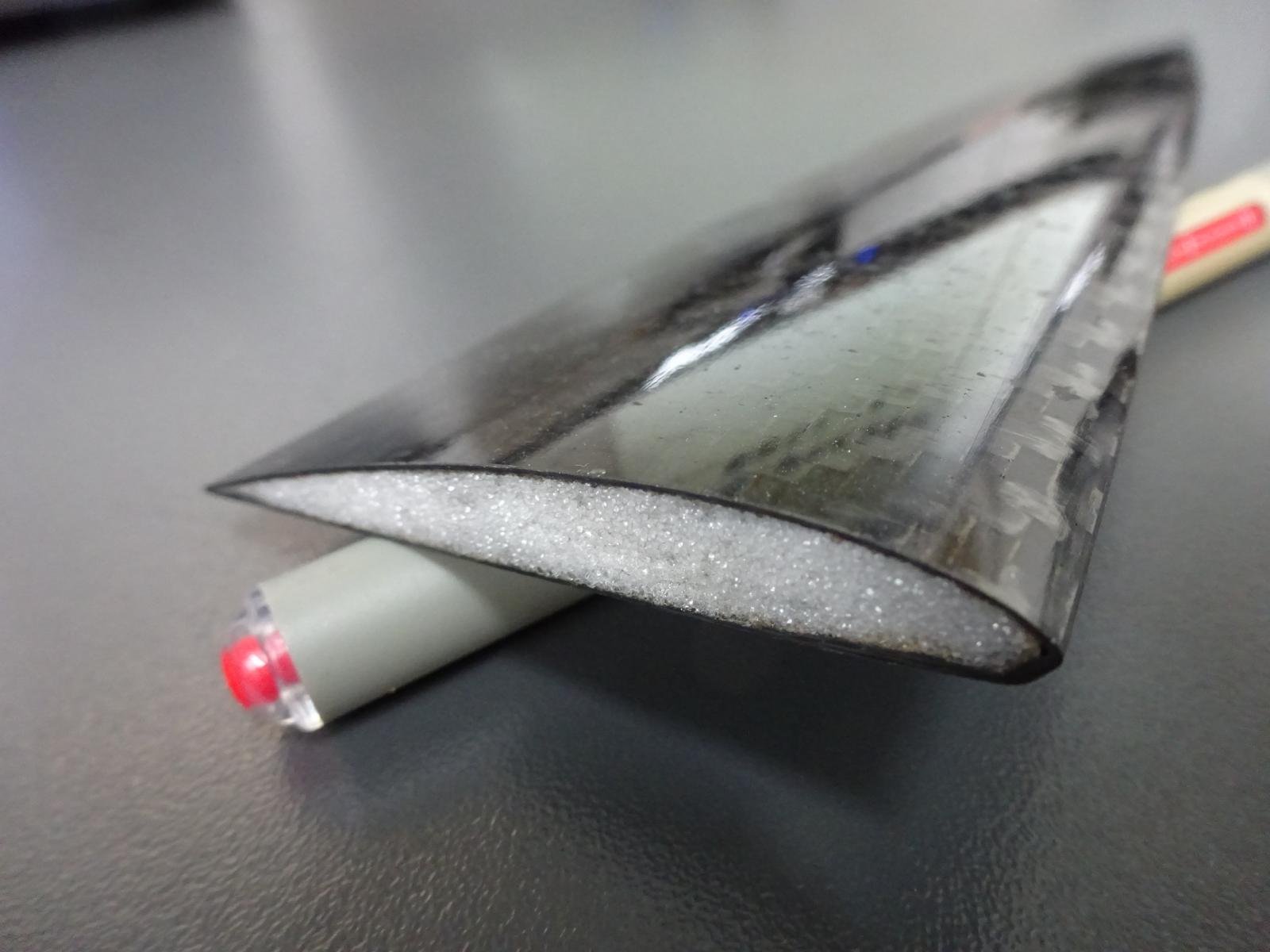

The new presses will be on stream in October. Presses are used to apply the heat and pressure needed to cure raw composites materials into components and structures. These are used in a wide range of industries including aerospace, defence, nuclear energy and medical technology.

In addition, the company has invested in a high-specification Hurco CNC machining centre to complement its increased laminating and pressing moulding capacity.

The addition of the new machinery and workforce will enable higher production levels of components and tooling, to meet growing demands from a diverse range of customers. This will open further opportunities in the aerospace, defence, fusion energy, cryogenics and composites sectors.

BACK TO ENGINEERING CAPACITY NEWS PAGE