Here’s our second look at some of the companies exhibiting at Subcon – see them at the show next week.

Machining capabilities

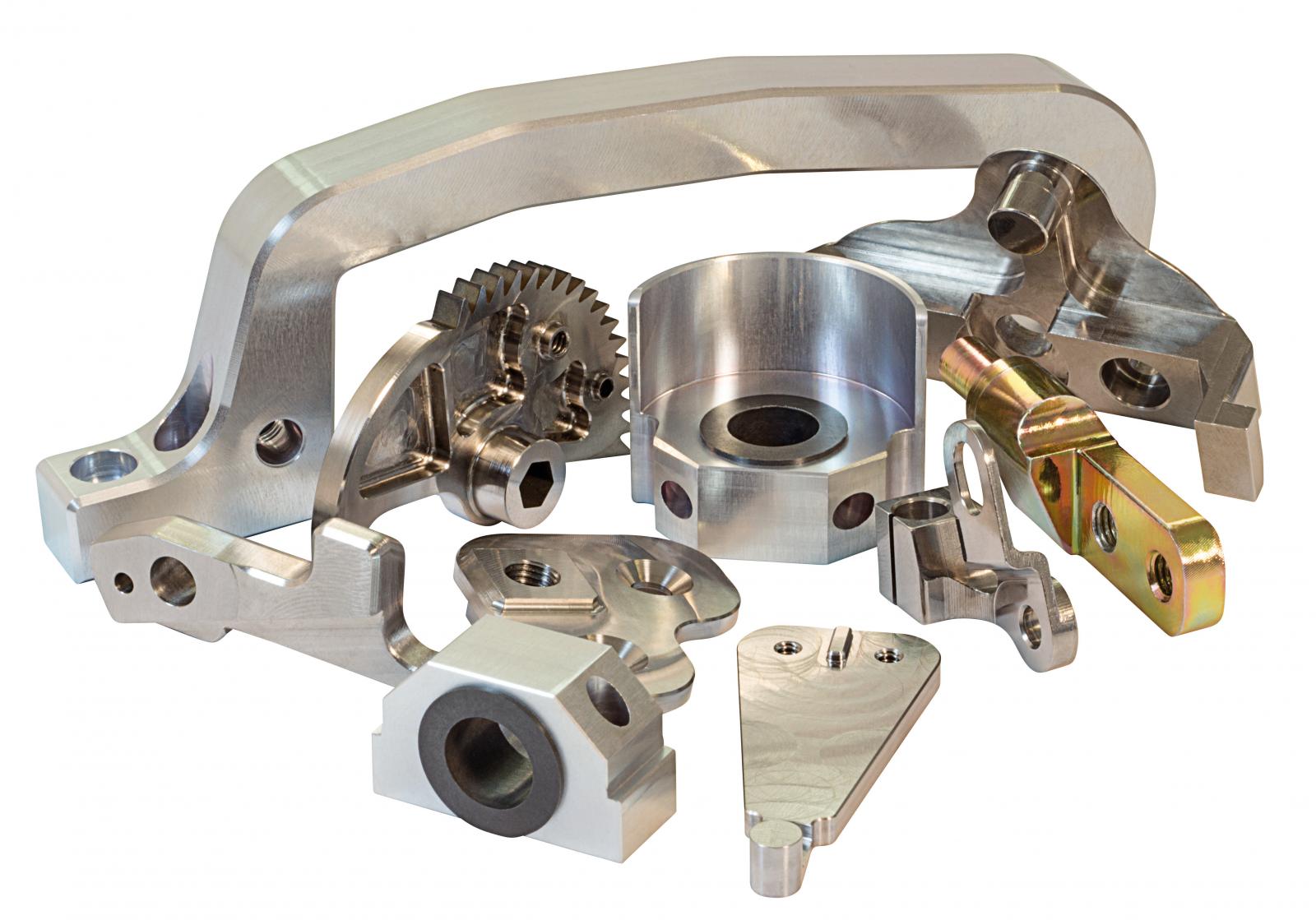

Mini Gears Group (Stand J17) will show the new range of machined components it can offer since investing heavily in its milling and gear cutting capacity for customers in nuclear, medical, defence, rail and aerospace. Visitors will see the type of precision machining the company now undertakes at its facility in Stockport where it has over 100 machines and 90 staff. Mini Gears helps customers turn concept designs into functional and manufacturable products and can often reduce manufacturing costs.

Electrical supply partnership

EMS specialist NOTE (Stand E37) has started a collaboration with the Swedish company Micropower, which manufactures electricity supply products. Manufacturing has recently begun at NOTE's plants in Lund and Pärnu of PCBAs and box build for lithium ion batteries, which are delivered to Micropower in Växjö, Sweden.

Ultrasonic welding services

Telsonic (Stand G15) is seeing increasing demand for its subcontract ultrasonic welding service for both plastic and metal. Customers include manufacturers who may require additional production capacity, or perhaps do not have sufficient volume to warrant the purchase of dedicated equipment. Telsonic’s subcontracting service also allows customers who are having bespoke systems built by Telsonic, the opportunity to manufacture components using the same ultrasonic technology until such time as their system is ready for delivery, an ideal scenario for pre-production or low volume production.

Spring investments

Over the last 12 months, European Springs & Pressings (Stand D40), has invested over £2.5m in its factories with a further £1.5m invested more recently in a number of new advanced technologies. A new powder-coating line has been installed in a 700 sq. metre extension, a new heat treatment oven acquired and two high-performance spring-end grinding machines complete the recent purchases in Cornwall.

IN BRIEF

Macsa ID: D71

Macsa ID will be showing its upgraded iLaserbox 450 laser marking workstation at the show. Described as being ‘ideal for first time laser users’, the more ergonomically designed unit now features a lateral instead of vertical door for improved ease of operation. The newly enhanced Macsa’s iLaserbox 450 can be switched to Class 4 mode for marking large or irregular part configurations, making it perfect for high value, low volume applications within a range of industrial markets, including automotive and aerospace.

MIE Solutions:

MIE Mobile Warehouse is a warehouse management application developed by MIE that lets you control inventory, receive and ship items, select goods from a pick list, and clock in and out of timesheets. The app provides an intuitive and easy to use graphical interface that communicates with the new MIE Platform, a web-services platform offering the same technical framework as MIE Trak Pro. It’s currently available an Android app.

Waveney Precision:

Waveney Precision has added a new 5-axis milling machine to its existing line-up of milling, turning, and EDM technology. The DMU 50 is from DMG MORI’s DMU series of universal machining centres.

Business development manager Jamie Walker said: "We endeavour to be highly receptive to our customers’ needs. We have been getting more and more requests for machined parts that suited 5 axis machining and, even though with our expert team of engineers we managed to produce 80% of these parts using 3 and 4 axis machines, we will now use this new milling centre to improve our productivity and increase our capabilities.’’

DP Engineering: 44

Precision sub-contract engineering firm DP Engineering has recently invested in a new Citizen L20X sliding head machine to increase capacity. By moving to become a fully digitised business in 2019, the company will be able to offer increased productivity for customers.

Logan Electronics:

Logan Electronics, which provides a sub-contract manufacturing service to aerospace, defence companies and OEMs, has recently secured a major contract with an aerospace prime and taken on additional staff.

Diamond Metal Screens: F38

India's largest sheet metal and perforated metal manufacturer will be at Subcon to showcase its increased capacity and new perforation presses, as well as sharing details of its brand-new manufacturing plant and ability to export worldwide.

Red Box Engineering

Red Box Engineering is over 50 years old and continues to grow, including recent investing in new machinery, such as our new Press Brake, allowing for increased capacity.

E-Max Systems: A41

If you’re a manufacturer or engineer who’s fed up struggling with spreadsheets/legacy systems, managing your MRP, dealing with multi-level large bill of materials or never knowing what capacity you have at any point in time, then take a visit to E-Max. The business has added new financial functionality into its powerful manufacturing software, E-Max ERP, and is showcasing the new version of our Shop Floor Data Collection. The team will be on hand to offer brief introductory demonstrations of E-Max ERP and comprehensive walkthroughs.

Turnell & Odell: D31

Turnell & Odell can now offer additional capacity working with Tordoff Engineering – the range of plant includes all disciplines from 3, 4 and 5 axis CNC machining up to 1500mm, to lathes that vary from small bar feed machines to others with 3000mm between centres. Together with AS9100 and Fit4Nuclear accreditations, the company is well set to take on projects across a broad range of industries.

Statii:

Statii is disrupting the ERP/MRP industry with its innovative software. Aimed at manufacturing companies, Statii throws down the gauntlet to be the simplest system in the UK. Don’t be fooled by the sheep’s clothing by its simplistic interface, the company constantly strives to maintain the ‘keep it simple’ ethos but is as powerful as any other system at the same price point. Managing everything from quoting, through to invoice Statii, is an all-encompassing tool.

JFL Broaches & Broaching: A4

Drop by the stand and help the team celebrate 10 years in business. From small beginnings in 2009, JFL has grown to a team of seven and is awaiting delivery of another broaching machine to further enhance its sub-contract capacity.

Rencol Components:

With a long tradition of standard component manufacturing, the team will be showcasing its newly expanded range of enclosure hardware. Its updated range includes industry standard cabinet locks, cam locks, cylinder locks, latches and adjustable toggle latches. All parts are available from stock and represent exceptional value.

Precipart:

Even after almost 70 years in business, Precipart continues to grow by leaps and bounds.

“We have just about doubled its manufacturing campus in the US over the last five years, opened an office in Bangalore and will be cutting gears there within the next couple of months, and the Swiss office has added its EN9100 registration, which means we are now 9001, 13485 (medical) and 9100 (aerospace) registered across the company,” said a company spokesperson.

Sanford Electrical Service:

Visit the Sandford stand to find out how they have invested substantially in the latest automation solutions.

“Design and manufacturing is now semi-automated, meaning our bespoke electrical control panels can now be installed far more efficiently; our design and manufacture process is more streamlined, reducing our time-to-market by 30-40 per cent. We are also presenting an interactive exhibit showing how our enclosures are wired quickly and easily with the help of EPLAN Pro Panel Software,” they said.

CNC Leicester

BSI AS9100 Accredited CNC Leicester has recently expanded to a second site in Sileby, Leicestershire, and has invested in vapour blasting, vibratory rumbling and chemical blacking to increase its competitiveness, allowing customers to benefit from increased efficiencies and technical support.

Advance Northumberland:

Advance Northumberland will be hosting the Northumberland Pavilion at Subcon again this year and will be brining a delegation of five manufacturing businesses operating in the supply chain that are looking to grow or diversify their business.

With many UK and international companies having chosen Northumberland as their base to grow and thrive, the county has become home to some of the most technologically advanced manufacturing and engineering companies in the world. It has a long-standing manufacturing tradition maintained by a diverse group of outstanding businesses. Access to skilled local labour, excellent transport links and access to regional universities and centres of excellence all contribute to Northumberland being a truly competitive and great business location.

Thermal Vision Research: A71

Thermal Vision Research will showcase its new FLIR’s X6900sc, presenting new opportunities for the highspeed R&D community.

Wilson Pro:

2018 saw Wilson Process complete its transition over to ISO9001:2015 while successfully winning new business in the audio, medical, lighting and energy meter sectors. This year, Wilson will move towards implementing ISO14001 along with expanding on its number of IPC trained operators to enable greater diversity of skill set across an ever-evolving customer base. New equipment at the business, includes two Soltec 7038 reflow ovens bringing the total number to four with plans for two more precision screen print machines giving increased flexibility across their current four high speed lines.

XYZ Machine Tools:

If it’s automation you’re looking for, be sure to visit XYZ, who will have a robot-based automation cell – ROBO-TEND – taking centre stage. This modular and mobile robot automation system is designed for use with XYZ vertical machining and turning centres fitted with Siemens controls. The system will be demonstrated attached to an XYZ 750 LR vertical machining at Advanced Manufacturing.