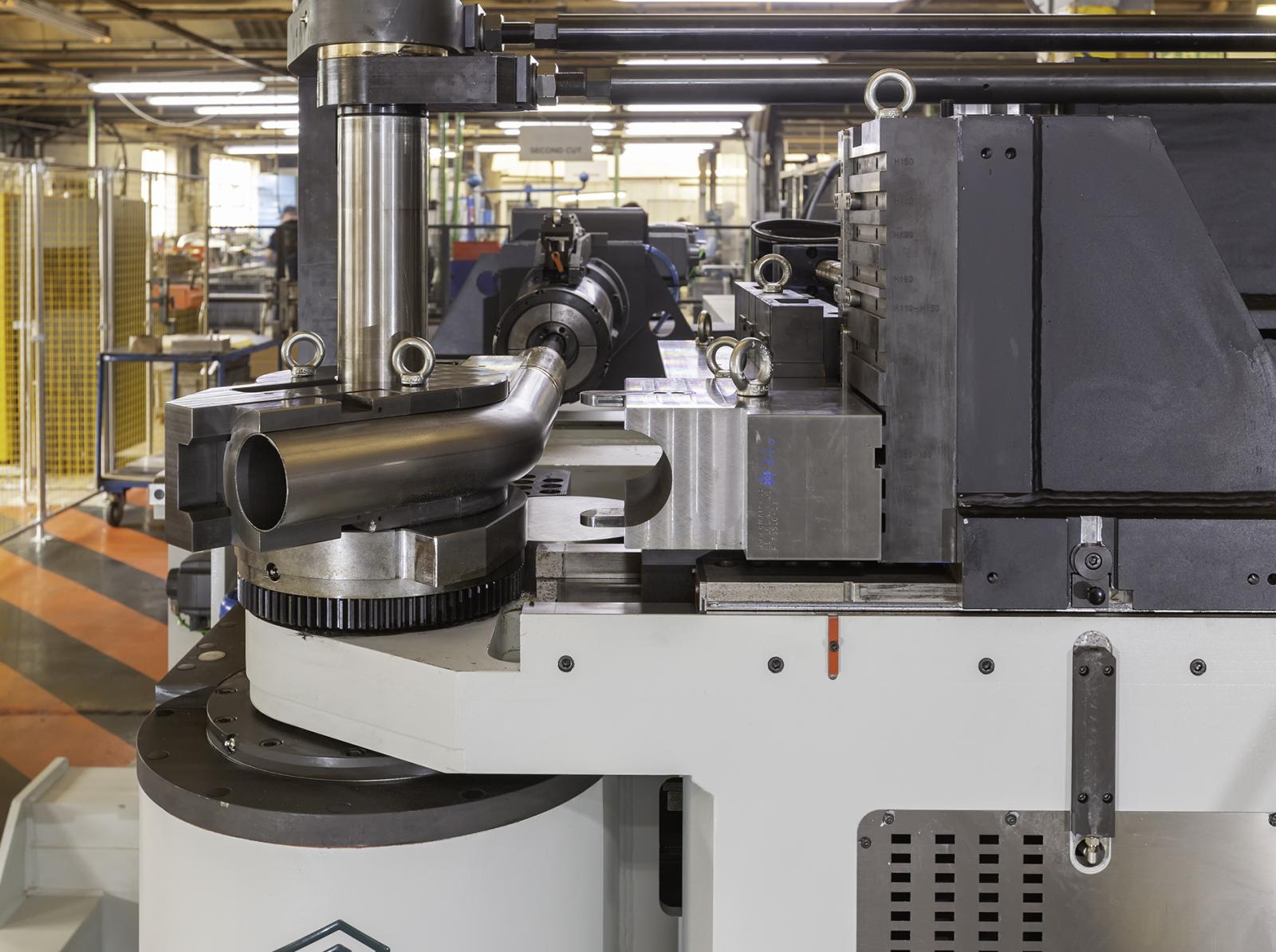

New tube bending equipment at Lander Group’s Malvern facility will increase capacity, eliminate production steps and improve quality.

The BLM ELECT 150 All-Electric CNC Tube Bender can bend tube up to 152 mm (6”) diameter, with added efficiency delivered by the multi-stack tooling system where up to eight tool sets can be mounted simultaneously, the BLM ELECT 150 will add to the group’s overall capability and allow further expansion of its growing customer base.

Lander Group has boosted its tube bending capability and will open up new markets with a major investment plan.

David Alexander, Sales and Marketing Manager, Lander Tubular Products, said: “This new machine will add to our lower volume, high complexity work at Malvern through consistent quality, reduced potential leak paths by eliminating the need to fabricate, cut and weld larger diameter tubes, reduced process times and the confidence we have from our experience of BLM.”

With the acquisition of Malvern Tubular Products and Maxpower Automotive from Tricorn UK towards the end of 2021, the Lander Group created the opportunity to continue its development as a single source of supply for tube-based assemblies. Now, under the branding of Lander Tubular Products, and with the latest investment in BLM tube bending equipment, the group has the capability to provide automated tubular solutions from 4 mm through to 152 mm diameter in a range of materials, including steel, stainless steel and aluminium.

“When Lander Group acquired Malvern Tubular Products and Maxpower Automotive, it was evident that they had suffered from a significant lack of investment in capital equipment over recent years. Our vision is to update all of our facilities, within the constraints of the current economic climate,” said David Alexander.

“At Malvern we focus on lower volume production of larger tube diameters, often with higher complexity of bends, mainly for the off highway, construction and power generation industries, with the new BLM machine we can look to expand into new market segments with our fully finished tubular products.”

Given the scale of the BLM ELECT 150, some 18,000 kgs, this puts Lander Tubular Products in a strong position to win new work by combining its now extended bending capabilities with its existing customer support for design, prototype development through to full production. While large scale, the machine is extremely versatile and brings greater control to production through its control system.

The machine’s variable torque system allows torque to vary between 2 and 6 metric ton to eliminate part deformation, even on tight radius bends and, the surface finish of the tube is maintained to the highest levels.