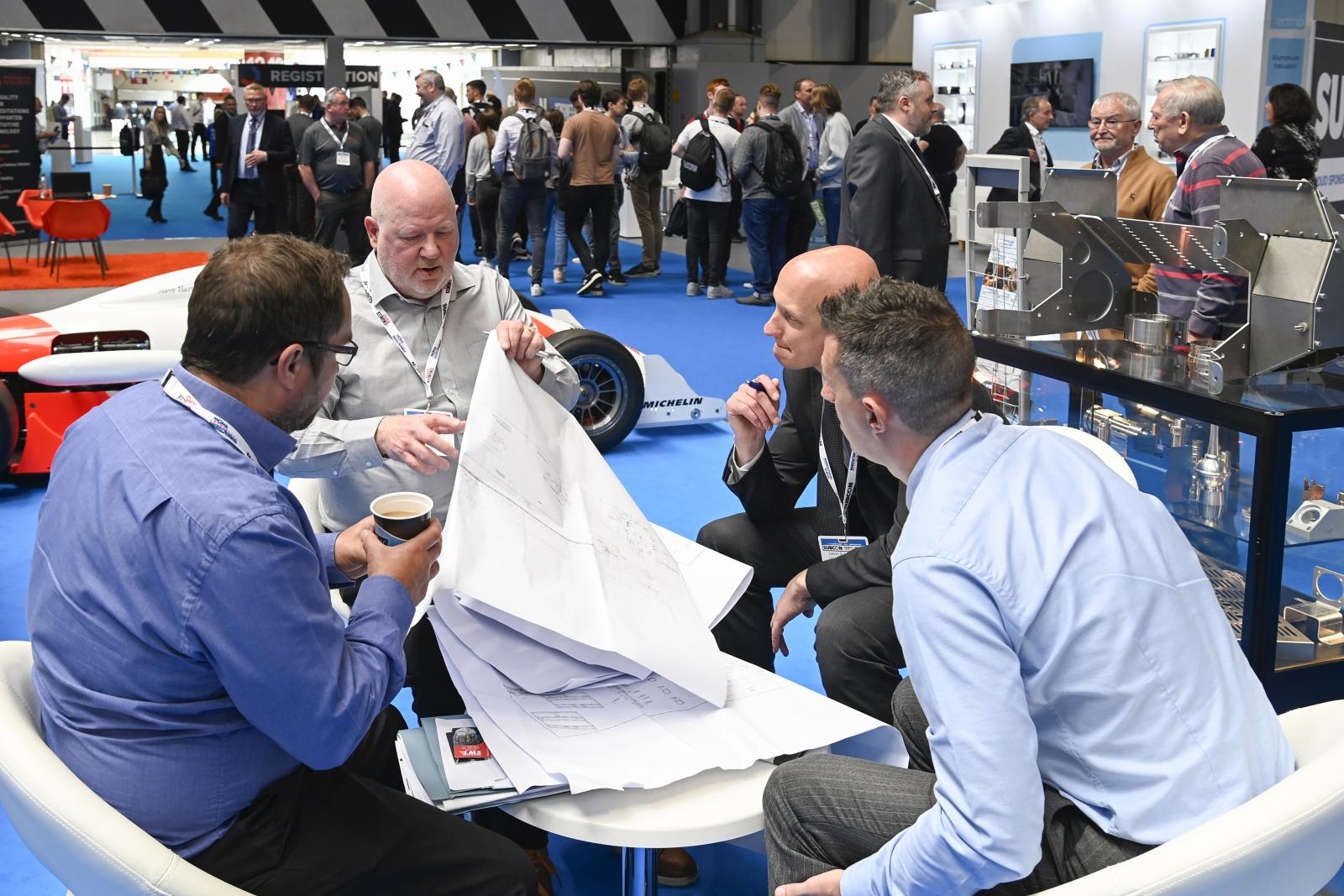

With over 200 exhibitors and thousands of products and innovations on display, Subcon is a must-attend event for the engineering sector. Here are some highlights of what is on show.

Bag sponsor for the show is Omnidex (Stand C141) a British-owned and managed company providing a single-source provider for all manner of metal and plastic fabrication, casting, machining, finishing, assembly and other manufacturing services, from concept to completion.

Registration sponsor for the show is Turkish Machinery (Stand D121) , the Turkish Machinery Exporters’ Association, which represents and promotes the interests of its 18,000 members in Europe’s sixth largest machine tool sector.

The Turkish machinery sector has recorded robust growth over the past decade and has increased by more than 400% since 2003. It is now Turkey’s second largest exporter, worth some $25.5bn in 2022 – equivalent to 10% of total exports.

Citizen Machinery (Stand A119) combines two leading manufacturers of CNC automatic lathes: Cincom sliding head lathes up to 38mm, and Miyano fixed headstock lathes from 36mm up to 80mm. Citizen offers highly productive and cost-effective solutions for your complex metal-cutting requirements.

Cornelius Electronics (Stand A121) has become a well-known and leading subcontract manufacturer of box build, bespoke cable assemblies and wiring harnesses, serving a variety of industries. The company says it has the has the technology to deliver repeatable, quality-controlled and scalable production quantities to help your business.

EDMO (Stand A141) is a bespoke aluminium extrusion supplier. Its complete range of extrusion and machining services is complemented by powder coating and assembly divisions. The services are delivered by a global network of specialists, keeping prices competitive and lead times short.

For more than 40 years, Faro (Stand E109) has been a pioneer in ‘Reality Capture’; bridging the digital and physical worlds through data-driven reliable accuracy, precision and immediacy, providing industry-leading technology solutions that enable customers to measure their world and use that data to make smarter decisions faster.

JKN Oil Tools (Stand C119) is a Precision Engineering Company based in West Yorkshire producing high-quality subcontract machined parts and fabrications to customers’ specifications and on-time delivery. It supplies components and fabrications to a large variety of customers, including major pump manufacturers, valve companies, food machine manufacturers and a wide range of smaller sectors.

Keyence (Stand A99) has steadily grown since 1974 to become an innovative leader in the development and manufacturing of industrial automation and inspection equipment worldwide. Its products consist of code readers, laser markers, machine vision systems, measuring systems, microscopes, sensors, and static eliminators.

Modula Storage Solutions (Stand E128) provides customers with effective storage solutions. Modula manufactures automated storage solutions offering one of the most advanced picking systems in the Vertical Life Module market. Modula is headquartered in Salvaterra di Reggio Emilia, Italy and Lewiston (ME) in the USA. Modula also distributes its services worldwide.

Oldham Engineering (Stand C129) is an established subcontract medium to heavy engineering business. Its services include precision CNC machining, fabrication, welding, robotic welding, mechanical assembly, equipment refurbishment, turnkey projects and project management. It can both batch manufacture and produce bespoke smaller quantities and one-offs.

Powdertech Surface Science (Stand G120) provides technically advanced powder coating and surface treatment services to the automotive, medical and specialist niche sectors. Customers benefit from expertise built on years of experience in highly regulated industries, together with the scientific knowledge of a well-qualified team.

Shropshire Stainless and Aluminium (SSA) (Stand G123) is a metals and plastics stockholder based in the UK and Ireland specialising in the supply and processing of aluminium and stainless steel from European suppliers.

Vector Blue Hub (Stand F108) is a specialist electronics design and manufacturing services company based in Poland. It offers an ‘Under One Roof’ concept, where the design and manufacturing services remain in one place to accelerate time to market.

Grenville Engineering (Stand D120) aims to impress attendees with its expertise in metal fabrication solutions. In addition to showcasing its fibre laser cutting technology and metal forming capabilities, Grenville Engineering is also excited to showcase its plans for new investments in tube laser and robotic welding.

The Tube Laser, due to be installed in September this year will allow Grenville Engineering to cut and shape tubes with precision and speed, complementing the Trumpf and Bystronic fibre laser technology, making it easier to create complex structures and designs.

Sales Director, Stuart Rawlinson explained "The investments in the new tube laser and robotic cowelder are an important move for Grenville Engineering. By staying up-to-date with the latest technology, we can remain competitive in the market and continually improve our services to customers, whilst reducing lead times and increasing our capacity. With the ability to offer a wider variety of parts, we can expand our customer base and attract new business".

The Robotic Cowelder will work alongside the current 22 welding stations and enable the company to automate some of their welding processes, leading to faster production times, increased efficiency and consistently high welding quality.

Stuart explained, "We're off to a great start this year and continue to grow. Therefore, we require these investments to keep up with both our current and future customers."

Midtherm Laser (Stand A89) a specialist subcontract laser cutting and forming specialist, is reaping the operational and environmental benefits from one of the largest purchases in its history. It increased its capacity and processing speed thanks to the installation of a new Bystronic Bystar Fiber 12kW laser with part automation. The machine will help the company deliver high cutting dynamics and thin-to-thick cutting capabilities to a customer base that ranges from aerospace and automotive to food and agriculture.

The investment has also made a huge difference to the firm’s environmental performance, with the Bystronic model replacing two older CO2 machines and is already delivering a 50% energy saving – the equivalent of powering 2,100 average homes every month.

Midtherm Laser works with more than 500 companies across 20 different sectors, cutting and forming various sheet metal from 0.5mm to 30mm.

Subcontract electronics manufacturing company DVR Ltd (Stand A129) has introduced a low-cost, fast-turnaround prototyping service to enable design engineers to rapidly evaluate new and innovative electronic concepts. With a few simple clicks, its new prototyping service Speed Assembly Services (SAS) can deliver custom-made PCB assemblies in as little as 24 hours, depending on component availability and lead time.

Integrated electronics manufacturing services (EMS) provider Escatec (Stand E108) has established a dedicated Innovation Hub. The facility, located 200 metres from its site in Switzerland, will provide Escatec’s design and development team with a creative workspace to meet customers and support them in turning their conceptual thoughts and early design ideas into market-leading products.

Established in 1974 with its headquarters in Penang, Malaysia, Escatec offers a fully integrated portfolio of electronics, electro-mechanical, and box build manufacturing services with a network of modern production facilities in Malaysia, the Czech Republic, the UK, and Switzerland.

See all the exhibitors and register for your free ticket now