Sigma Components has invested over USD$1m in its manufacturing facilities in the UK and China to increase capacity and meet growing customer demand.

The investment includes specialist equipment to boost the aero-engine and airframe applications components manufacturer's fabrication and pipe manufacturing capabilities. It has also led to the creation of over 50 jobs in Nuneaton, Hinckley and Farnborough.

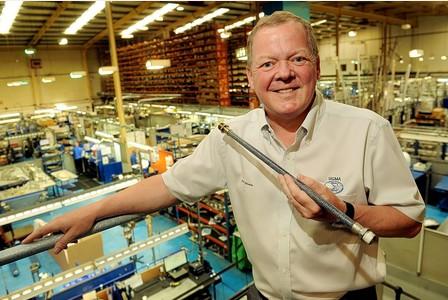

Mark Johnson, founder and CEO of Sigma Components, said: “Our sites across the UK and China work hand in hand to offer a high-quality, local source for customers. While some manufacturers may look to lower-cost economies simply to outsource the production of basic components, we take a longer-term approach.”

The investment follows its investment of more than USD$1m in a new manufacturing facility in Chengdu last year, which created additional capacity for its rigid pipe-manufacturing programme for Rolls-Royce's XWB engine, in particular.

The company has announced record growth in the 12 months since its change of ownership, with sales growing by 46%.

It stated that innovations from its SigmaLite range of lightweight aerospace components are moving from concept to reality as several R&D projects for aero-engine and airframe applications move into test phases with OEM support.

COMPipe - a composite aero-engine pipe that delivers weight savings of 50% over traditionally-manufactured pipes - has attracted considerable interest since the results of the CleanSky-funded R&D programme were announced at Farnborough Air Show in 2014.

Lab tests demonstrated that the thermoplastic composite pipe is capable of withstanding operating temperatures of up to 165°C, operating pressures of up to 450 psi and a typical engine operating environment, including fireproof requirements.

The flagship technology is now undergoing application-specific testing, with results expected towards the end of the year.

The Sigma Lite range includes new products and works in progress from Sigma's ongoing R&D programmes. These programmes have been supported by investments from the National Aerospace Technology Exploitation Programme (NATEP), the UK Government's Sharing in Growth programme, the EU-funded CleanSky programme and the Advanced Manufacturing Supply Chain Initiative (AMSCI).

Mr Johnson commented: “Moving on to engine testing is a significant step forward for the COMPipe project and a key stepping stone towards seeing the technology used in flight.

“While each new component in the SigmaLite range is an exciting development in its own right, the real step change comes when you look at how modest weight savings in a single fitting can create a massive snowball effect, greatly reducing the overall cost, size and environmental impact of manufacturing and running an aircraft. For example, our figures suggest that using composite rather than metallic pipes could offer total weight savings of approximately 10kg per engine. The knock-on effect for the rest of the aircraft is likely to magnify that, delivering empty weight savings of 50kg for a twin-jet aircraft.”