Addmore Engineering draws on the expertise of its tooling supplier to meet customer needs on complex and intricate components.

Based in Bedford, the company supplies high-precision parts to the automotive, medical, oil and gas industries. What started from a barn in Watford is now a large operation which spans over 3 buildings, employs 48 skilled machinists and runs 24 hours a day.

Addmore turned to Ceratizit over 20 years ago to help it with its complex component and tooling needs.

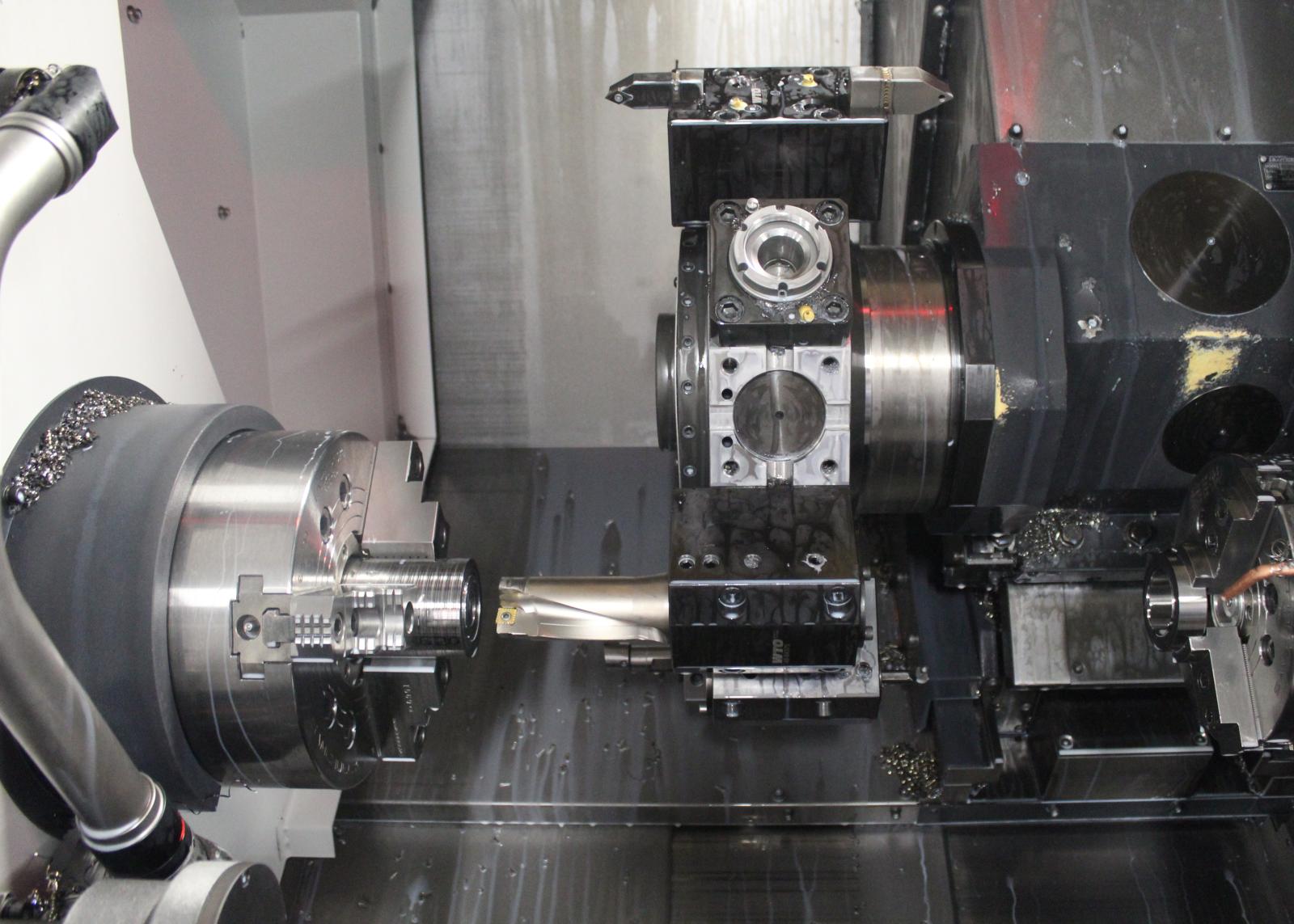

Recently Addmore started using Ceratizit’s Pentron Drill in order to increase tool life and save money on tool-replacement costs.

Whereas the previous drill had an insert life of between 55-75 parts per edge, the Pentron drill increased this to 120+ parts per edge, making an improvement of well over 50%.

As well as the cost-saving benefits which come from the extended insert life of the Pentron drill, switching to this insert also meant that machine cycle time was reduced by 10%, allowing for more parts to be machined per day.

Addmore has Ceratizit vending machines on-site which allows it to access new tools as and when they are needed. Enabling 24-hour access to tooling and parts on hand to prevent machine stop-time aren’t the only benefits that were highlighted by Addmore MD Ben Vasquez, as he also pointed out how useful it is to be able to see the company’s tooling costs for specific parts and machines.

Ben was also keen to highlight how Ceratizit goes beyond simply selling tools and providing a catalogue of products. The 24/7 access to technical support is just as valued as the high-quality tooling for Addmore.

“I don’t want to look through a brochure and guess what the best solution would be”, explained Ben. “I want to talk to someone who understands what I need and who recommend to me, then and there, the right tool for the job. I know I can pick up the phone and speak to them if I have any problems. If these problems require tooling to solve them, then these are delivered the next day as well.”

BACK TO ENGINEERING CAPACITY NEWS PAGE