HOW DOES A FLOAT SWITCH WORK?

Float switches are used as the standard instrument for liquid level control in many applications, such as pump control, valve control and level alarms, due to the need for reliability and repeatability. Often called a mechanical level switch or magnetic level switch, they detect the liquid using three basic components, a float, a magnet and a switch.

The simplicity of the product is its strength. There are various designs on the market, but essentially they all work the same; the float becomes buoyant and lifts when a liquid rises to the point at which it is located or the float falls when a liquid drops below its location. The rising and falling float either contains the magnet and moves it over the switch, or it moves a lever containing the magnet which changes the switch.

Buoyancy – a simple theory

The float has a known weight in air acting downwards due to gravity (downwards force).

When the float is placed in a liquid (e.g. water) there are two forces acting on it:

- The float’s weight (downwards force).

- The force of the water pushing up (upthrust force).

If the weight is equal to or less than the upthrust, it floats.

(Check out Archimedes’ principle for a greater understanding of buoyancy and the effects of liquid density and volume of the float).

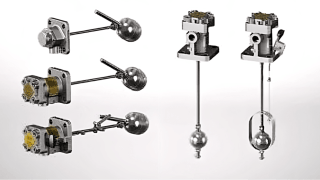

A liquid level float switch normally falls into two categories. Based on access to the location in which the switch is required to operate they are a vertical float level switch or a horizontal float level switch. More on the different types of these can be read in our types of float switches (add link) blog article.

How a float switch works - vertical

A vertical float switch normally uses the “magnet in a float” design; the float is hollow and has a tube fitted through the middle, the magnet fits around the tube inside the float and the float is mounted onto a stem or support tube with clamps fitted to the tube to keep the float located at the required point where a switch is needed. The vertical float level switch uses a reed switch level sensor which is switched on (activated), switched off (deactivated) or changed over (always activated) by the magnet passing over the point at which the switch is fitted in the support tube.

Vertical float switches are normally installed through the roof of a tank, or using a bracket to mount to a wall, floor or other fixing point. By putting a ninety degree bend in the tube, side up and side down versions can be also be installed in the side of a vessel. This vertical design allows multiple switches to be installed in the support tube enabling dual level float switches with some multi-level float switch designs allowing up to five switch points through one stem.

There are other vertical float switch designs which are covered in more detail in our types of float switches (insert link) blog, these include some with a pivot system which are best used for fluids with a low density due to the float size options, paddle floats which are common for sump pump applications and displacer float switches where switch points may need to be changed or installed on floating roof applications.

How a float switch works - horizontal

The principle of operation for a horizontal float switch is fundamentally the same, with a float rising, causing a magnet to move and activate or deactivate a switch. These float switches are normally mounted from the side of a tank or in a bracket at the point where a switch point is needed. Unlike vertical float switches, the horizontal switch does not have the magnet in the float, instead the float is mounted on the end of a stem which houses the magnet in its end. When the float rises the stem pivots and moves the magnet towards the location of the switch which is normally in the connection head or connection head stem, and the magnet causes the switch to open or close. Another difference with side mount switches is that they can be manufactured with a microswitch instead of a reed switch.

The float switches that AMS manufacture were originally supplied by Alan Cobham Engineering and have been manufactured in the UK for over 50 years. We continue to manufacture float switches in the UK from our premises in Cornwall with a wider range of connection options and bespoke solutions now available to suit more applications. For more information please contact us, download our literature or visit the float level switch section of our website https://ams-iac.com/level-measurement/float-switch/