If you prepare your drawings for laser cutting correctly, it will help to streamline your order process, enabling us to get your order out to you as quickly as possible.

The file formats we accept for laser cutting are DWG, DXF and NC.

SPECIFY MATERIALS AND QUANTITIES

- What material would you like us to cut?

- How thick?

- Grade and finish (if appropriate)

- Please specify the orientation you require for the grain (if required)

- Quantity required

If you aren’t sure what exact material suits your purpose, take a look at our materials pages or call our sales team for some advice on 01376 327182.

2D DRAWINGS ONLY PLEASE

All drawings will need to be supplied in a 2D format. At Lasered Components we only cut flat components from sheets of metal. Our expertise is in the cutting, not in developed parts.

CHECK ALL DIMENSIONS

Please check every dimension on your drawing before sending them. Our internal auditors will check them to make sure nothing slips through the net, but this will add time to the turnaround of your order as we will have to contact you to verify the corrections.

The maximum part size we can cut is 2980mm x 1480mm.

DURBAR / TREAD PLATE

If you order tread plate, please make it clear on your drawings which face should have the pattern.

SINGLE CONTINUOUS LINES

Try to make the drawings of your components continuous single lines wherever possible. If there are gaps or breaks in lines, our lasers will treat each line as a separate cut, stopping and starting where the lines stop and start which can result in an irregular edge.

TOLERANCES

One of the main advantages of laser cutting is the accuracy, our laser cutting tolerances are +/-0.25mm. Depending on the final requirements of your product, you may need to apply some edge finishing to your components, so please make allowance for this if required.

LEAD-INS

A lead-in is essential to the laser cutting process, ensuring that the laser enters the cut line smoothly but it does result in a lead-in pip, a small bump on the outer edge of the component. We will add lead-ins for you on the drawings as part of the setting up process, so there is no need for you to add these on your drawings, unless you have a specific requirement. In these cases, this will need to be discussed with the sales team to ensure your component is as you require whilst making sure the laser cutting process goes as smoothly as possible.

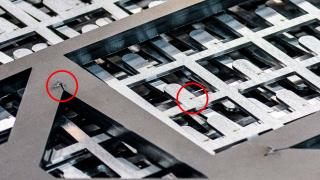

CORNERS

Our software will add a 0.5mm radius on all angles of your metal components on all thicknesses, this is applied to internal and external cuts. This aids the cutting process, making it faster and smoother and resulting in a neater corner with reduced burr. On most laser cut components this radius will be barely noticeable but if the pieces you require have very acute inner angles, you might lose a bit of the end, and if it has an extreme reflex angle you might gain a bit of material on the inner edge.

ANY OTHER PROBLEMS…

Our auditors check every part on every drawing before sending them to production, if anything appears to be incomplete or does not look correct we will contact you to check it.