Welshpool based foundry Castalum is using metal additive manufacturing technology to produced advanced die-casting moulds.

CastAlum is an aluminium foundry using high pressure die casting and squeeze casting to supply a range of engineered components for the automotive sector, with 90% of all production being for export.

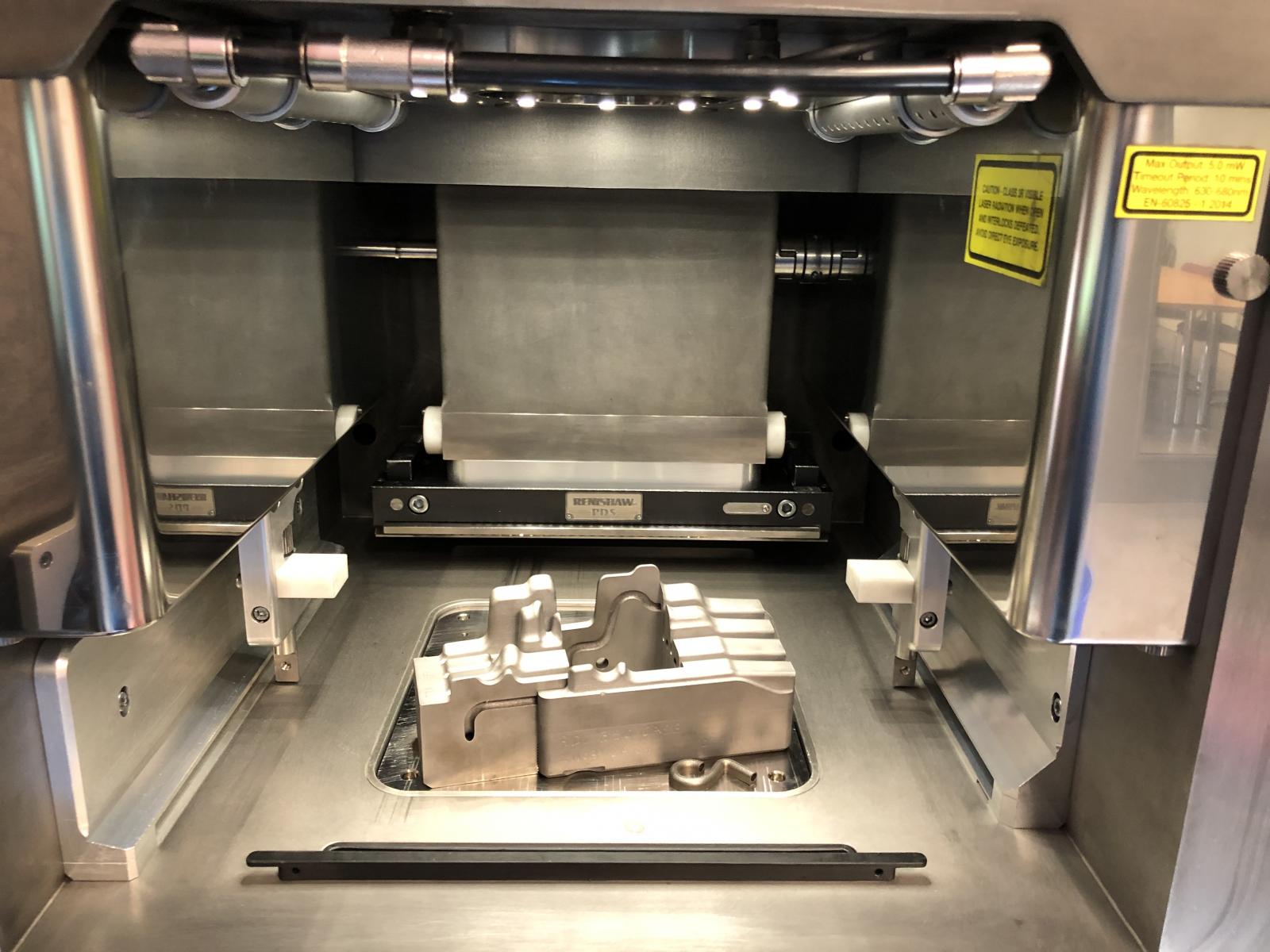

Investment in new technology and a greater understanding of additive manufacturing (AM) technology, through a 9-year programme of research and development, means that CastAlum is now the first company based in Wales, outside of a university, to independently run a powder bed selective laser melting, SLM, machine.

Back in 2000, the site was a greenfield development, with only one customer. The company now offer cast and machined, or fully assembled and tested parts as required by the customer. Indeed, over 20 years the company has built up to a diverse customer portfolio, supplying castings to the automotive industry. The company now has 10 high pressure casting cells ranging from 1100 tonne to 2200 tonne and 3 squeeze casting cells, alongside 14 3axis machining centres. Components manufactured by the company go into vehicles produced by VAG, FCA, BMW, Ford, Porsche, Mercedes, JLR, AML and other prestigious marques.

By 2014, the company was already an early adopter of AM technology, working closely with an Italian company developing conformal cooling techniques in tool steel, with promising early results. “With the good came the bad” explains CastAlum AM Engineer, Rhys Jones. “Despite the overall equipment efficiency, the variables in tool life and high part costs where simply unjustifiable in a competitive commercial business - something had to change.”

However, the potential benefits that additive manufacturing could bring to HPDC were too great for CastAlum to simply ignore. Successfully securing a collaborative R&D award with InnovateUK in 2018 allowed the company to accelerate progress with the technology and work to iron out the early issues.

“The parts that we look to produce on the SLM printer aren’t the traditional 3D printed parts that most of us are familiar with, with lightweight lattice structures and thin walls. The parts that we need are large, dense parts that are capable of withstanding the harsh environment of high pressure die casting,” explains Rhys.

“The SLM process really consists of micro-welding. The machine lays down a thin layer of powder (in our case it’s 40 microns thick) and then the laser superheats the powder, fusing it to the layer below; layer by layer the part is formed. With our large, bulky parts, the more the laser has to melt, the more welding splatter and smoke is generated. This dirties the build chamber over time and can potentially degrade the quality of the part as it is built up - this is where we need to work smarter to overcome this issue and maintain part quality,” he explains.

The first step in making a tooling insert on the printer is consider its geometry and determine if it can be built on a SLM printer. Tooling inserts naturally have draft angle for releasing the casting out of the die, this suits the printing process as this means that the geometry is self-supporting and can build without support. The next task is to lay out the cooling channel, and tie this in with the company’s process department and inhouse toolroom, capture their feedback and model it in.

“As all our 3D modelling is caried out in house, this allows us to be very flexible and dynamic when it comes to design changes, we can make the small changes needed to optimize performance” says Rhys. “We use file preparation software from Renishaw to lay out the build and set the build parameters. The printer runs largely independent for the entire build, only needing brief operator intervention to look after the powder. Once we are all happy with the design, we can print it and our builds tend to run from around 80 hours to 120 hours, depending on the part size.”

Once the build has finished, the powder is removed from the part, and it is then taken for final machining. The parts straight off the printer have a rough finish, unsuitable for use in the casting process, so to overcome this the company adds a small machining allowance and a 3 axis XYZ mill to fully finish the parts providing a much better surface finish and ensuring the dimensional accuracy of the parts.

Through the Innovate project, the team at CastAlum worked closely with experts from Coventry University whose role was to develop methods of calculating the amount of cooling needed at each point of the casting, to allow a much more efficient and uniform cooling of the mould and greater optimisation of the process.

Rhys also notes that his team “were very lucky to be able to work with engineers at Renishaw’s solution centre, based up in Stone, where we had access to Renishaw’s considerable AM knowledge. The solution centre allowed us to learn how to use the new technology in the safety of their facility. Through this collaborative team approach, our increased understanding of conformal cooling, combined with the ability to implement and use this knowledge has now enabled the team at CastAlum to change what was thought feasible”, he added.

Key to this was the company’s “Forward Focus” ethos which drives change, as customer needs grow, to meet the new challenges of Electric Vehicle (EV) and Low Carbon Vehicle (LCV) technology.

Rhys is excited about the future. “We now have a wealth of experience and data that we are confident will enable us to support the development of lightweight casting technology without sacrificing properties or durability. We continue to develop additive manufacturing for the foundry industry, developing a number of process solutions to meeting world class quality standards and provide solutions to customers”