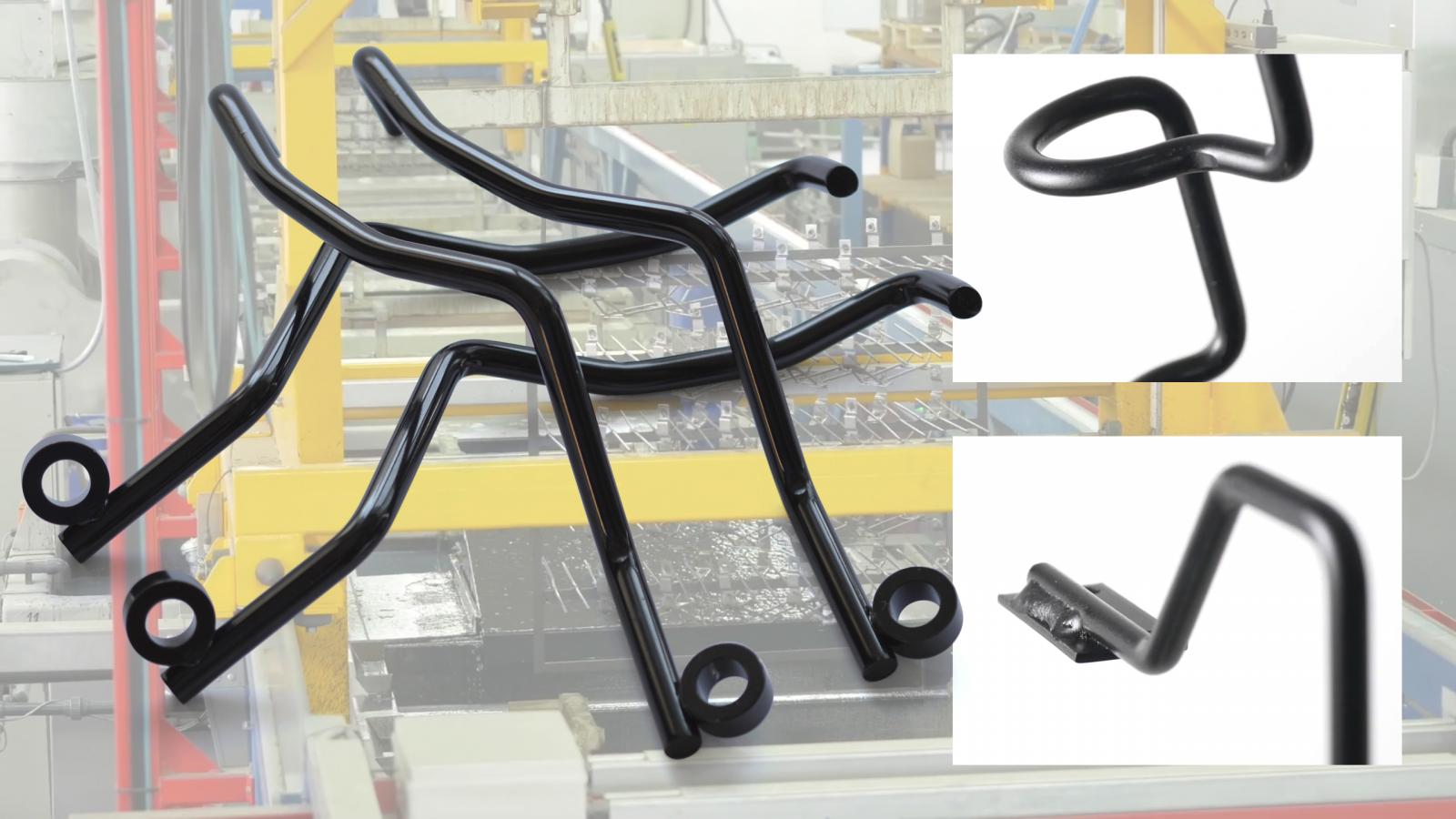

William Hughes can now offer electrophoretic coating to give a gloss black finish with strong anti-corrosive finish on the springs, wire forms and assemblies it manufactures itself and as a service to other manufacturers.

The new paint line has been installed at the company’s Plovdiv factory in Bulgaria.

Electrophoretic paint – or E coating – is a combination of plating and painting whereby a metal object is dipped in a water-based solution which contains a paint emulsion. An electric current passes through the part causing the paint emulsion to condense onto it. Both the outside of the part and any internal surfaces can be painted, provided the solution can reach the surface concerned.

Typical coating thickness is 20 to 22 microns but upwards of 40 microns can be achieved if required. Many of the parts produced by William Hughes are destined for use in the automotive seating industry for which the paint chosen is particularly suitable due to its anti-noise properties.

Cleaning is the first step in the process, using an alkaline cleaning agent for the removal of oil, grease and other surface contaminants prior to a rinse in tap water. Then comes an acid bath for more stringent cleaning followed by further rinsing and a passivation procedure designed to remove any remaining iron contaminants from the surface of the material.

A rinse in de-ionising water prevents bubbles forming on the surface of the part when it enters the electro painting, or KTL stage.

The paint line transfers the parts from tank to tank fully automatically in a closed loop system that eliminates waste and is both efficient and environmentally friendly.

Finally, the painted parts are cured in an oven set at 200 degrees for 20 minutes, and will now withstand corrosion for around 800 hours, according to tests conducted in William Hughes’ salt-spray testing facility.

You can see a video of the new William Hughes capability here