Redditch-based laser cutting and sheet metal specialist Intec Laser Services has created extra capacity for an automotive contract by investing in a fast, automated bending cell.

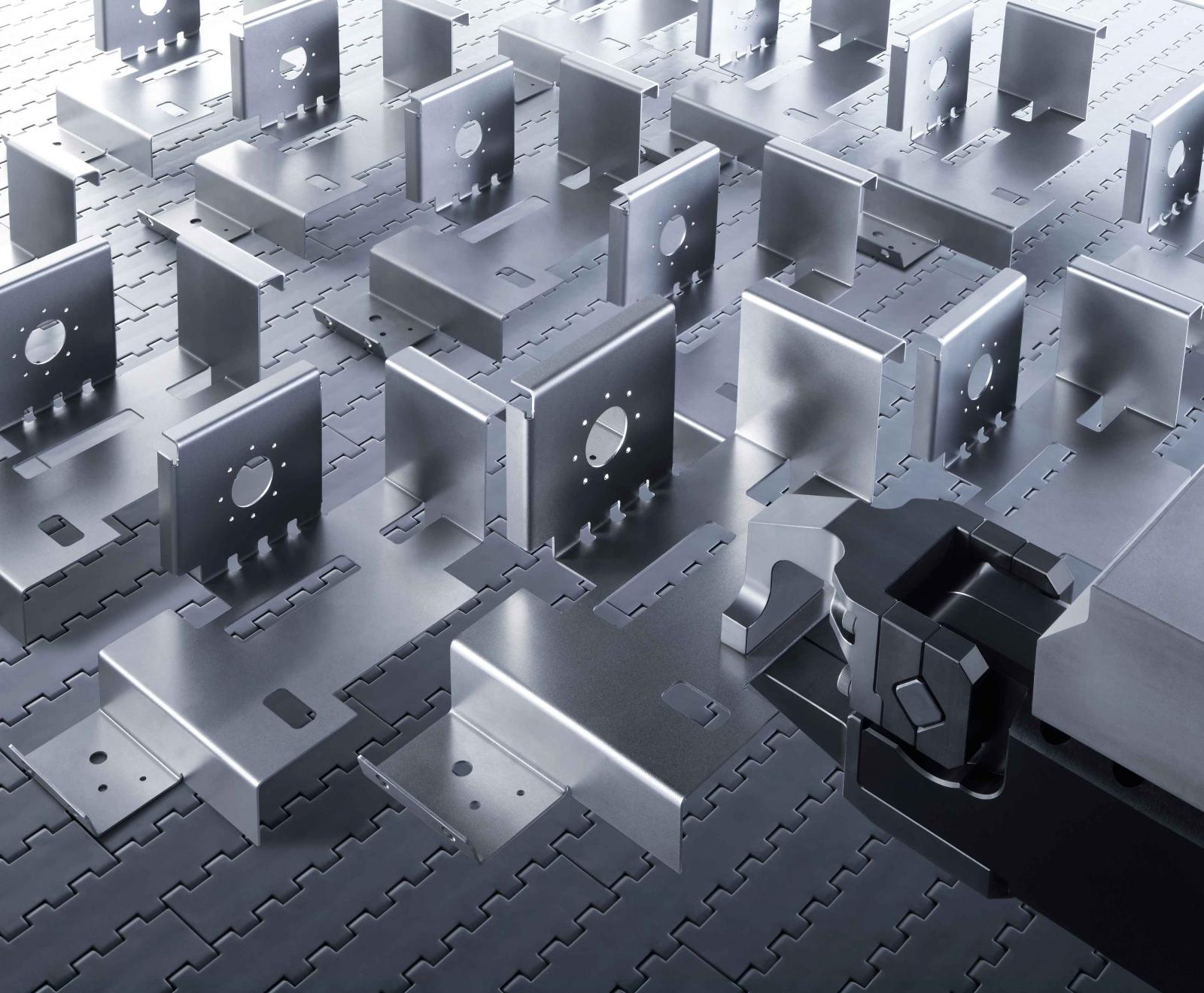

The Trumpf TruBend Cell 7000 is said to be one of the world’s fastest and has been put to work producing over 200 different types of brackets of various batch quantity and complexity for a range of customers.

Redditch-based lntec Laser Services was formed in 1979 and is one of Trumpf GB's oldest customers. The company has continuously invested in flat-bed laser cutting, tubular laser cutting, five-axis laser cutting and waterjet cutting services.

To complement the company's profiling services, lntec also offers a comprehensive range of secondary operations, including bending, welding and fabrication, essentially taking jobs from a sheet metal blank right through to a finished component or assembly. However, with a new automotive contract on the horizon, the rapidly expanding £3.5 million turnover company sought to boost its bending capacity and introduced a 24-hour automated operating system, increasing the previous bending capacity by some 70%.

"We recently won a contract for the automotive industry that required the manufacture of 100+ different types of bracket to be supplied in batches of around 300 and upwards," explains lntec's Managing Director Darren Marson. "With our extensive laser cutting capability we knew that component blanking would be straightforward. However, it was immediately apparent that our bending capacity would not be able to keep pace with the lasers and would therefore be the bottleneck process."

On average, lntec estimated that each blank would take just a few seconds to laser cut, but bending would take between 30 seconds and a minute using its existing manual press brakes. With this concern in mind, the company set out to acquire a more capable resource for the bracket contract.

"We decided on an automated bending cell, scrutinising most of the suppliers in this technology area," says Mr Marson. "There were many reasons we opted for the TRUMPF TruBend Cell 7000, not least its automated tool change. With so many different bracket types to produce, we knew this attribute would prove vital. The other machines we considered all required some level of manual intervention regarding the tool change function."

“Most of the brackets we process are produced from an A4-sized blank with various complexities, some single bends and others containing 10-12 bends. Brackets are produced in mild steel, aluminium and stainless steel, up to a maximum thickness of 5 mm. We are now looking at putting other jobs on the machine," says Mr Marson.