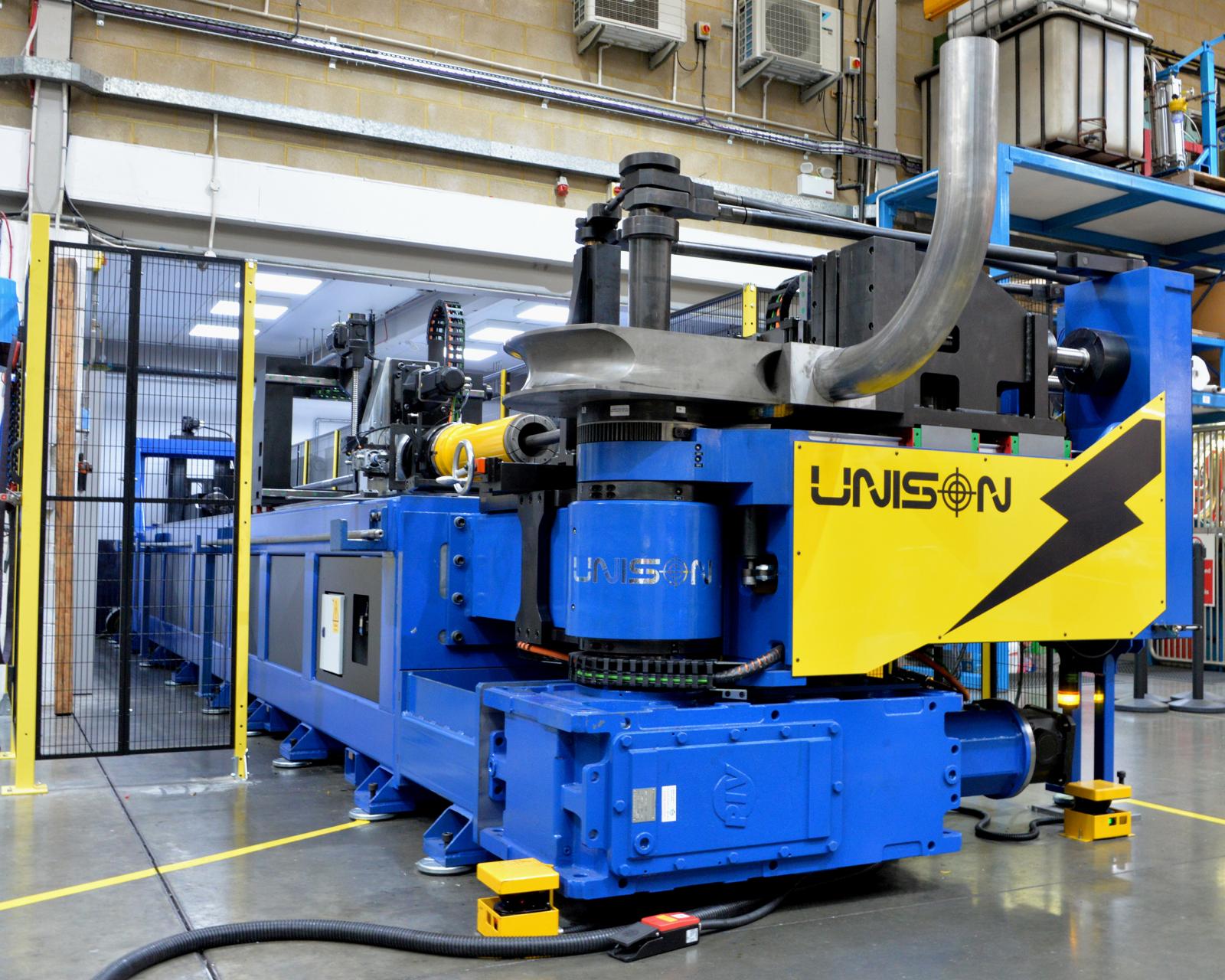

Tube manipulation and pipe bending subcontractor T&T Tubecraft has increased capacity with the installation installed of a new Unison all-electric 130 mm diameter multi-stack CNC tube bending machine.

This is the third Unison tube bender to be purchased by T&T Tubecraft since 2014. It joins a 50 mm Unison Breeze machine and a 100 mm Unison Breeze multi-stack model that are in daily use at T&T Tubecraft’s Woking-based facility.

“Of all our tube benders, our 100 mm Unison machine is easily the busiest,” comments T&T Tubecraft managing director, Ross Turner. “Ironically, when we purchased the 100 mm Unison machine back in 2015, we didn’t have a vast amount of work for it. This quickly changed, however, as we gained the ability to take on new projects. The new 130 mm machine will increase our capability even further, both in terms of capacity and the ability to tender for an even greater range of projects. We expect it to be of particular interest to customers in the aerospace sector.”

The 130 mm tube bender is particularly suited to bending exotic alloys such as titanium and Inconel, as well as super-duplex stainless steels. Able to push bend tubes of up to 6.2 metres in length when in standard mode, it also features a hitch-feed facility, whereby the machine carriage retracts by the length of the next feed, enabling mandrel bending of tubes of up to 8.7 metres long. As a result of this capability, T&T Tubecraft believes that, out of all UK tube manipulation subcontractors, it may provide the longest bending range.

Multi-stack tool holding allows the most complex of parts to be formed in one uninterrupted manufacturing cycle, while Unison’s bar code scanning system ensures that only the correct tools are installed while also configuring the machine automatically. The standard-fit rise and fall pressure die means that tools of very different radii can be used on a part within a cycle.

The power of the machine allows high quality thin wall bending, even on high yield-strength alloys such as Inconel.

The 130 mm machine has been networked to T&T Tubecraft’s CAD facilities and a coordinate measuring machine (CMM) for verifying bend accuracy and design conformity. The tube bender can be programmed manually or from CAD data using industry-standard IGES or STEP files, while data obtained by the CMM from the first manufactured part can be used to make automatic adjustments to the machine prior to commencing a manufacturing cycle.

“The all-electric architecture and automated Unibend software-controlled setup of our Unison machines offers major advantages over hydraulic machines,” continues Ross Turner. "Bending accuracy and repeatability are dramatically improved. We achieve right-first-time manufacturing for repeat subcontract work and typically expect even the first bent trial component at the start of a project to be very close to what we are looking to achieve. Machine configuration is also rapid, typically only taking 15 to 20 minutes. As a subcontract tube manipulation company, we also quickly get to hear how well new machines are viewed by our teams. Unison machines are very well received by our workforce. Unison’s Unibend operating software is exceptionally intuitive, meaning much faster programming and accelerated training for new staff members. Our operators consider the Unibend control system to be exceptionally user friendly.”