Thomas Brown Engineering is targeting the aerospace sector with its latest CNC machining investment.

Meeting the precision needs of its customers has seen a Huddersfield manufacturer make a number of large investments, including the acquisition of the latest CNC machine technology.

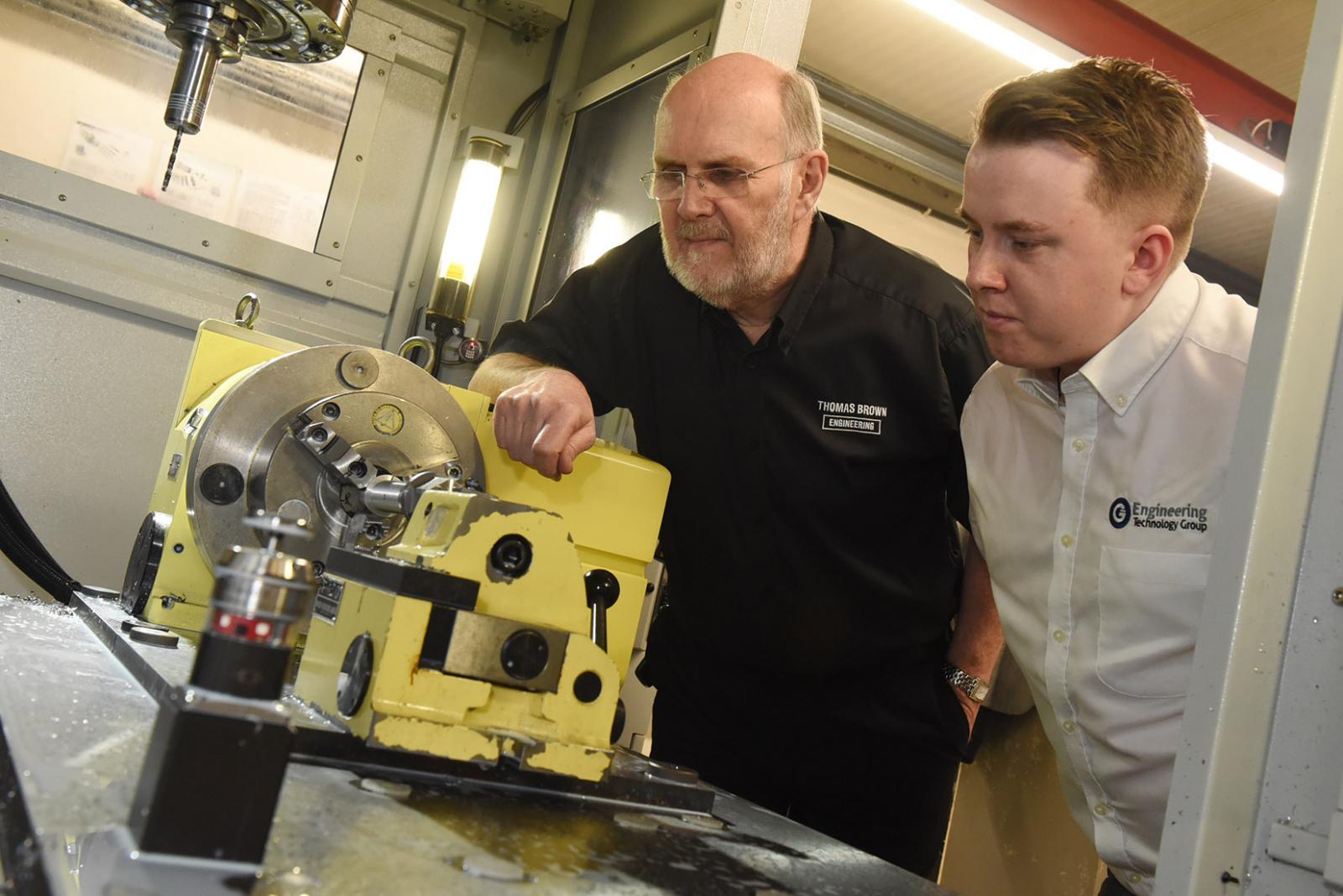

The Huddersfield-based subcontractor, which celebrated its 35th birthday in 2018, has worked with the Engineering Technology Group (ETG) to install a new Hardinge Bridgeport XR1000 to help it capitalise on three recent contract wins for the aerospace sector.

The machine is equipped with a Nikken 4th axis rotary table and a powerful GTW spindle that will allow it to machine the toughest materials.

Tom Brown, who founded the business in 1983 after serving an apprenticeship and working at a local firm, said:

“Aerospace is a growing market for us following our AS9100 accreditation and this helped us secure three important contracts, which required more capacity and shorter lead times.”

He continued: “We spoke to ETG about our requirements and came up with the XR1000, specifying it with a Nikken 4th axis rotary table to give us the opportunity to produce more complex components.

“It is a decision that is already paying off, with some cycle times reduced by as much as 20%. This makes a major difference to our productivity.”

The Engineering Technology Group’s extensive stockholding helped with a quick turnaround, equipping it with Heidenhain TNC 640 controls and an eco-cooling heat exchanger system to prolong the life of the spindle.

It also worked with Blum-Novotest to fit the metrology specialist’s TC50 spindle probe and ZX-Speed IR tool setting probe to achieve ‘on-machine’ workpiece inspection/evaluation and in process tool management.

www.thomas-brown-engineering.co.uk

BACK TO ENGINEERING CAPACITY NEWS PAGE