Subcontract machinist Plalite has invested in five-axis machining centres with turning capability rather than lathes that can mill.

Over the last year the company has invested in two Japanese-built Speedio M140X2 30-taper mill-turn centres from Brother to carry out work that requires both milling and turning.

Director Tony Bess says the multi-tasking capability of the machines was attractive: "The number of operations needed to produce a part is minimised, there are no concentricity issues, blending is perfect and the tolerances we are able to hold allows us to quote very accurate work."

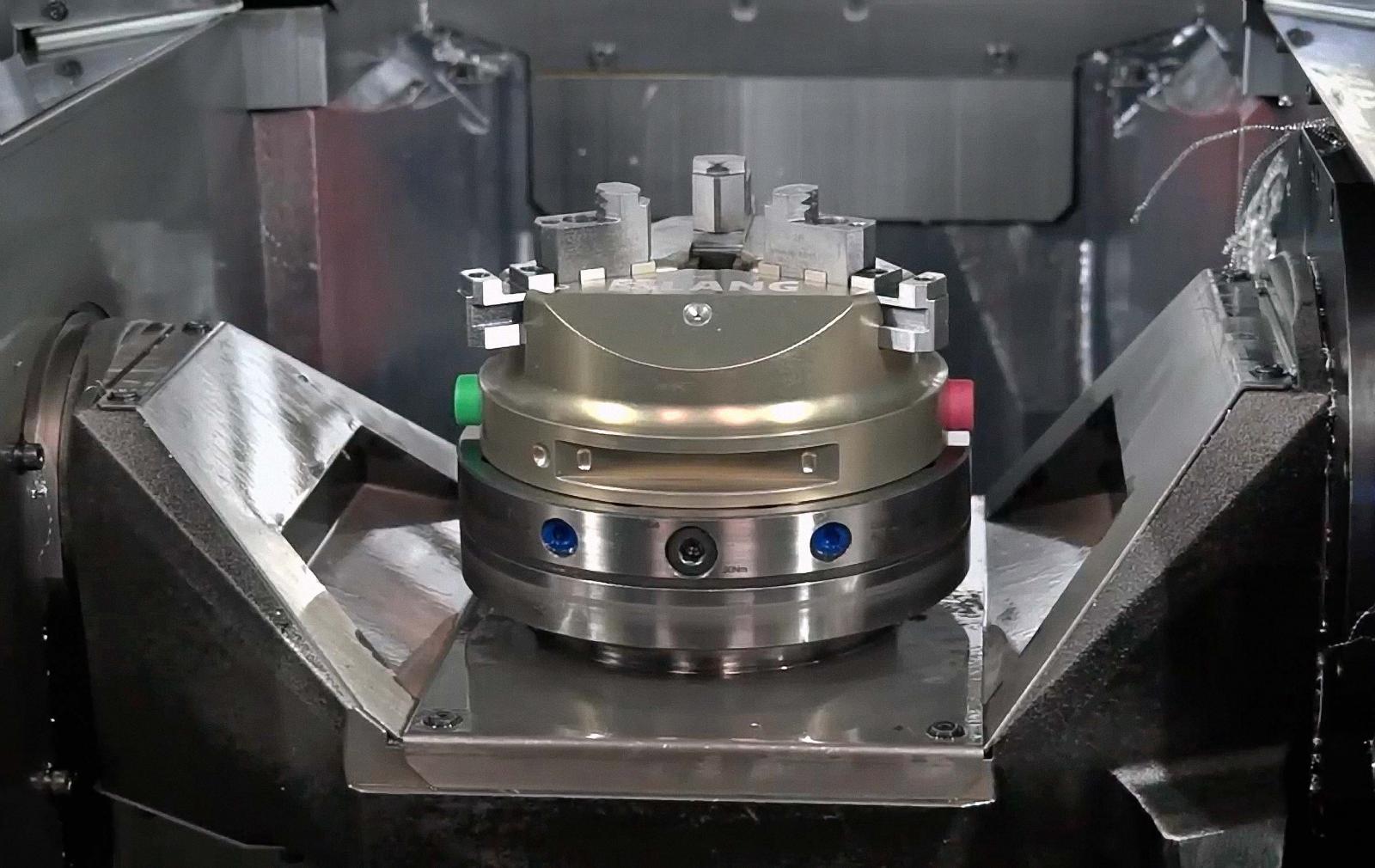

Short setup times using milling cutter back ends and the adoption of Lang zero-point quick-change chucks allow the machines to be changed over quickly, which is especially important when producing components in small batches.

When asked why he bought machining centres with turning capability, rather than bar automatics having live tooling, for one-hit production of what are often predominantly rotational parts, Mr Bess said: "With a turn-mill machine you get low milling capacity and a limited number of tools – compared with the 22 stations in the Brother turret - added to which driven tool heads on lathes lack rigidity, which tends to cause vibration.

"With a mill-turn machine you get quick, very productive prismatic machining capability, all the tools are in taper holders that are much more rigid, particularly with simultaneous face contact in the case of the M140X2 spindle, setup is a lot quicker and we suffer no issues when trying to hold tolerance.

"There are few restrictions on turning capability, as the direct-drive C-axis accelerates in a third of a second from zero to a maximum of 2,000 rpm, which is a third the speed of a typical lathe but sufficient for many of the jobs we produce. If higher revs are needed for turning a particular component, we simply put it on a lathe instead."

He concluded, "We engineer parts differently for production on the M140X2s to optimise productivity. Cutting strategies are altered and milling routines adapted, with more trochoidal milling for example, when a machining centre is used rather than a lathe.

"Provided it is the right kind of mill-turned part, each process route is highly productive on the two Brother machines, making us more competitive. We have certainly won new work on the basis of buying them."