Albert Tsang, Technical Manager, Precision Micro, explains how unique characteristics can be designed into products manufactured using photo etching such as conical openings used to direct fluid flow and how the process can reduce development costs.

As a precision sheet metal machining technology, photo etching achieves exacting tolerances, is highly repeatable and in many instances is the only technology that can cost-effectively manufacture precision metal components with the accuracy necessary in demanding and often safety critical applications.

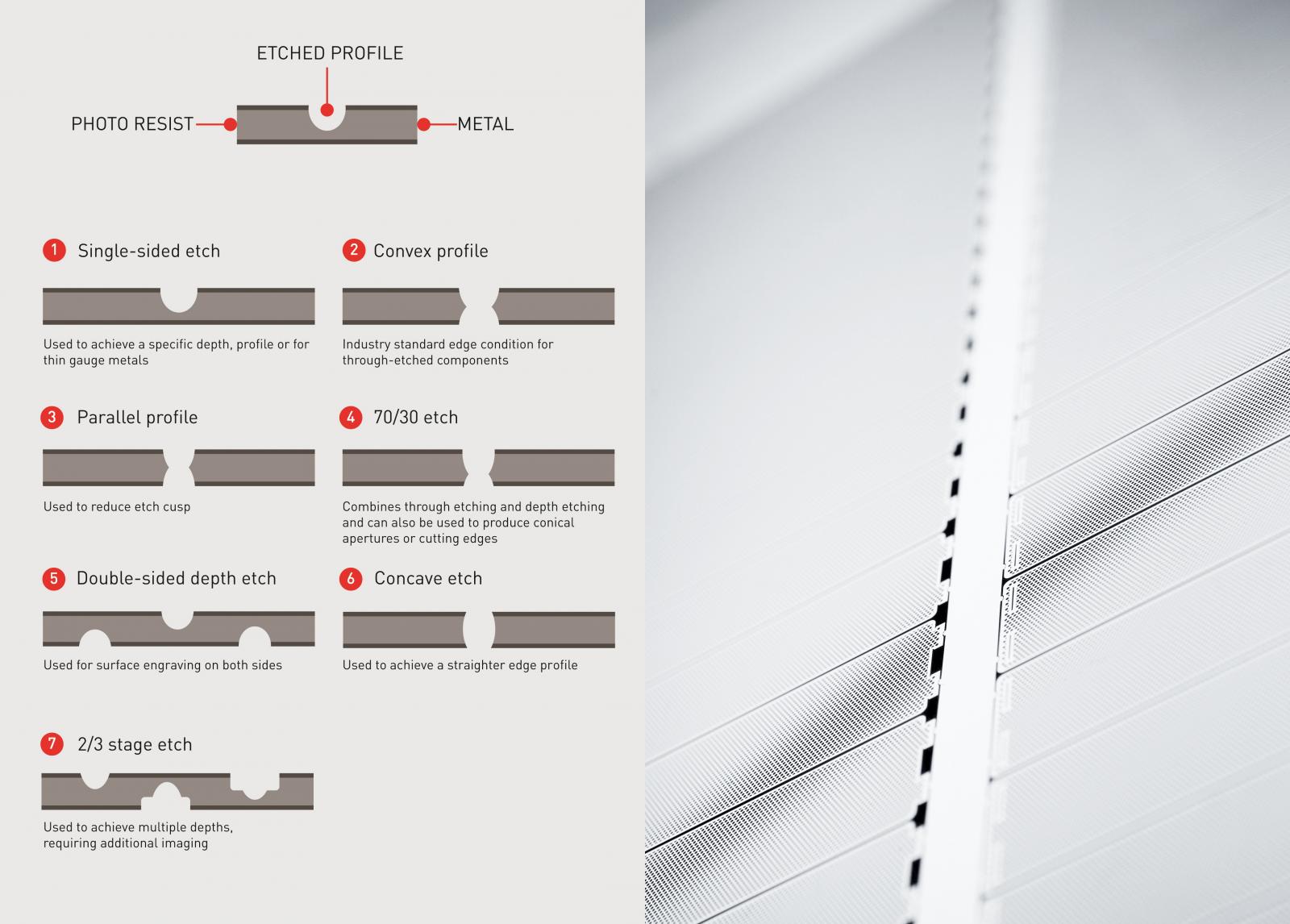

Unique features at no additional cost. Unique characteristics can be designed into products manufactured using photo etching due to the inherent edge “cusp” created during the process. Precision Micro can control etch cusp, and by doing so introduce a range of profiles allowing the manufacture of sharp cutting edges, such as those used in medical blades, or conical openings, such as those used to direct fluid flow in filtration meshes. (See Figure above)

Low-cost tooling and design iterations. For OEMs across all industry sectors looking for feature rich, complex and precise metal parts and components, photo etching is now the technology of choice as it not only copes well with difficult geometries, it also allows design engineers enormous flexibility, facilitating the adjustment of designs right up to the point of manufacture.

One major factor that allows for this is the use of digital tooling, which is inexpensive to produce, and therefore inexpensive to change even up to a few minutes before manufacturing commences. Unlike stamping, the cost of digital tooling does not increase with part complexity, which stimulates innovation, as designers focus on optimised part functionality rather than cost.

For traditional metal machining technologies, it is fair to say that increased part complexity equals increased cost, much of this being a product of the necessary costly and intricate tooling. Costs also escalate when traditional technologies have to cope with non-standard materials, thicknesses and grades, none of which have any effect on the cost of photo etching.

As photo etching does not use hard tools, distortion and stress are eliminated. Also, components produced are absolutely flat, with a clean surface and no burrs as the metal is dissolved away uniformly and evenly until the desired geometries are achieved.

Economical prototyping. With photo etching, you pay by the sheet, not by the part, which means components with different geometries can be processed at the same time from a single tool. This ability to produce many part types in one production run is the key to the enormous cost savings inherent in the process.

Photo etching can be applied to virtually any metal type, including those soft, hard or brittle. Aluminium is renowned for being difficult to stamp due to its soft nature, and laser cut due to its reflectively. Equally, titanium’s hardness can prove challenging. Precision Micro has developed propriety processes for both of these specialist materials and is one of the few etching companies in the world with a standalone, accredited titanium etching facility.

Add into the mix the fact that photo etching is inherently speedy (for example tooling typically takes a day to produce not 16 weeks!), therefore, being measured in days not months, and the rationale behind the exponential growth in uptake of this technology in recent years is obvious.

Conclusion

Design engineers are increasingly turning to photo etching as they are under pressure to create smaller and increasingly complex precision metal components. As with any process selection, designers need to be aware of the specific attributes of the chosen manufacturing technology when looking at design attributes and parameters. The versatility of photo etching and its unique advantages as a precision sheet metal machining technology makes it an engine for design innovation, and can truly be used to manufacture parts that would be deemed impossible if using alternative metalworking technologies.

Image Caption: Etch cusp can be controlled, and by doing so introduce a range of profiles allowing the manufacture of sharp cutting edges or conical openings.

*Albert Tsang is the Technical Manager at Precision Micro, Birmingham, UK. For over 50 years, Precision Micro has pioneered photo etching, a manufacturing technology using subtractive chemical erosion to produce burr- and stress-free precision metal components. The company creates highly innovative solutions to a wide range of engineering challenges using a 2-D process to create 3-D components that cannot be created with other technologies. Precision Micro offers a maximum sheet/component size of 600 mm by 1500 mm – one of largest sheet sizes in the industry.

Read more news from Engineering Capacity