A Protolabs’ survey of industry professionals at Moulding Expo in Stuttgart, Germany, revealed some of the key challenges – and opportunities – facing manufacturers across Europe.

Protolabs asked attendees three key questions about innovation and the future of production to gain an expert insight into the injection moulding industry and low-volume production.

The first question asked attendees how often they faced challenges in developing new products.

More than two-thirds (67 per cent) revealed they often ran into difficulties – with another ten per cent saying problems occured frequently.

Dirk Rathsack, Protolabs‘ Vice President of Sales for the EMEA region said: “The result here shows that Moulding Expo visitors need access to a streamlined product development process. With numerous challenges hindering a product’s journey to market, it could be that design engineers are not taking full advantage of rapid injection moulding technologies.”

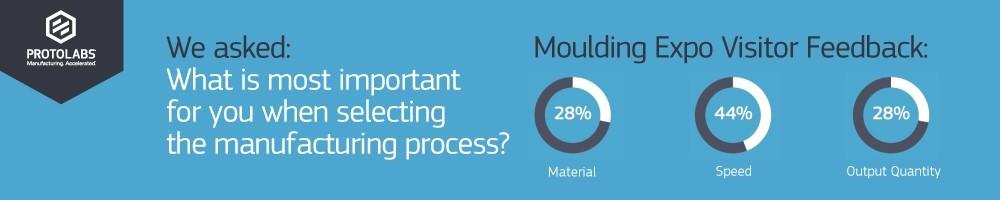

Attendees were then asked what the most important factor was in selecting the manufacturing process – material, speed or output quantity.

A total of 44 per cent highlighted speed as the key issue.

Mr Rathsack added: “This result demonstrates the need for Moulding Expo visitors to get their products to market quickly. With numerous iterations often required in order to bridge a part to full manufacture, rapid injection moulding is a key facilitator of speed-to-market.”

The final question asked professionals where they thought the key hub for low-production manufacturing globally was – Europe, Asia or the United States – with Europe coming out firmly on top with three-quarters of the responses.

Mr Rathsack added: “Despite the tremendous advancement of the manufacturing sector in Asia, the result here clearly shows that Moulding Expo visitors still highly value Europe as a manufacturing resource. Perhaps this means European manufacturers are embracing digital manufacturing and customisation more than the other regions?”

BACK TO ENGINEERING CAPACITY NEWS PAGE