Every growing company faces a quandary when it reaches a certain size – expand in-house production or outsource it to a reputable electronics sub-contractor. Steve Marshall, Managing Director of Offshore Electronics has good reasons for recommending the latter.

Successful electronic manufacturers typically start out by manufacturing their own products before experiencing growing sales and therefore, an expanding manufacturing operation.

However, rapidly growing companies can very quickly a victim of their own success. There will come a time when production is at full capacity and a new order comes in. These successful manufacturers then face a critical decision – should they further expand in-house production, or outsource to a reputable sub-contractor?

According to the Institute of Manufacturing at Cambridge University, getting this decision right is crucial to the future of a business: “Today’s global competition forces manufacturing companies to re-evaluate their existing processes, technologies, manufactured parts and services in order to focus on strategic activities. However, companies have finite resources and may not be able to afford to have all activities in-house.

“This has resulted in an increasing awareness of the importance of the make-or-buy decision, the dilemma organisations face when deciding between keeping technologies/processes in-house or purchasing them from an outside supplier. The ability to make such decisions in a structured and rational manner is likely to improve a company's overall performance.”

Offshore Electronics has discovered that, when making this type of decision, businesses tend only to examine the cost of materials without fully taking into account that investments must be made in factory space, machinery, and extra staff.

As a contract electronics manufacturer (CEM), our company provides outsourcing over internal expansion. Indeed, outsourcing makes sense in so many ways. Of course, letting go can be hard; for a company that is self-sufficient with an intimate knowledge of its products, the notion of handing it over to somebody else can be daunting.

Indeed, these fears can be well-founded. Intellectual Property (IP) – a concept or product that has been uniquely created by you or your company, and has the potential to add value to your brand and product range by creating more revenue or brand awareness – is exceptionally valuable.

A recent government report revealed that IP theft resulted in a combined loss of £9.2 billion in 2016. With such staggering statistics, manufacturers need to be sure they have the correct procedures in place to safeguard their IP. It is therefore vital to properly vet potential contract manufacturers before you start working with them and make sure they are honest and trustworthy.

Guernsey-based manufacturers, such as Offshore Electronics, have to follow strict rules when it comes to IP protection and our longstanding partnerships with world class customers are further proof that we are a company that can be trusted with your most valuable assets.

The New York Times summed up the benefits of employing a CEM as including:

- Greater efficiency, giving your firm an important competitive advantage.

- Lower labour costs, allowing your human resources to be redistributed where they are most needed.

- Reduced risk, outsourcing providers use their expertise to manage all aspects of specialised production, from compliance with governmental regulations to specialist industry standards, ensuring all products are safe to use

A CEM partnership also enables electronics companies to concentrate on what they’re good at – designing, marketing and selling electronic products.

A progressive CEM will enhance its host company’s reputation by adopting a laser-like focus on manufacturing: it will have the specialist staff and machinery, manufacturing capacity, buying power and – crucially – expertise in compliance to ensure that the final product is top class.

Although CEMs are perceived as being best suited to large companies, they work closely with many small and medium enterprises (SMEs). Indeed, a CEM can lend credibility to small electronics producers. If they are working in a small facility, making products by hand, they may not be getting the repeatability and product quality needed.

They may also be too small to handle ISO accreditations, or meet evolving compliance. Regulations are becoming more of a challenge, especially for small, design-led companies. Because CEMs have economies of scale, we can handle all this and more – everything from buying components, assembling the products, testing and shipping the final product.

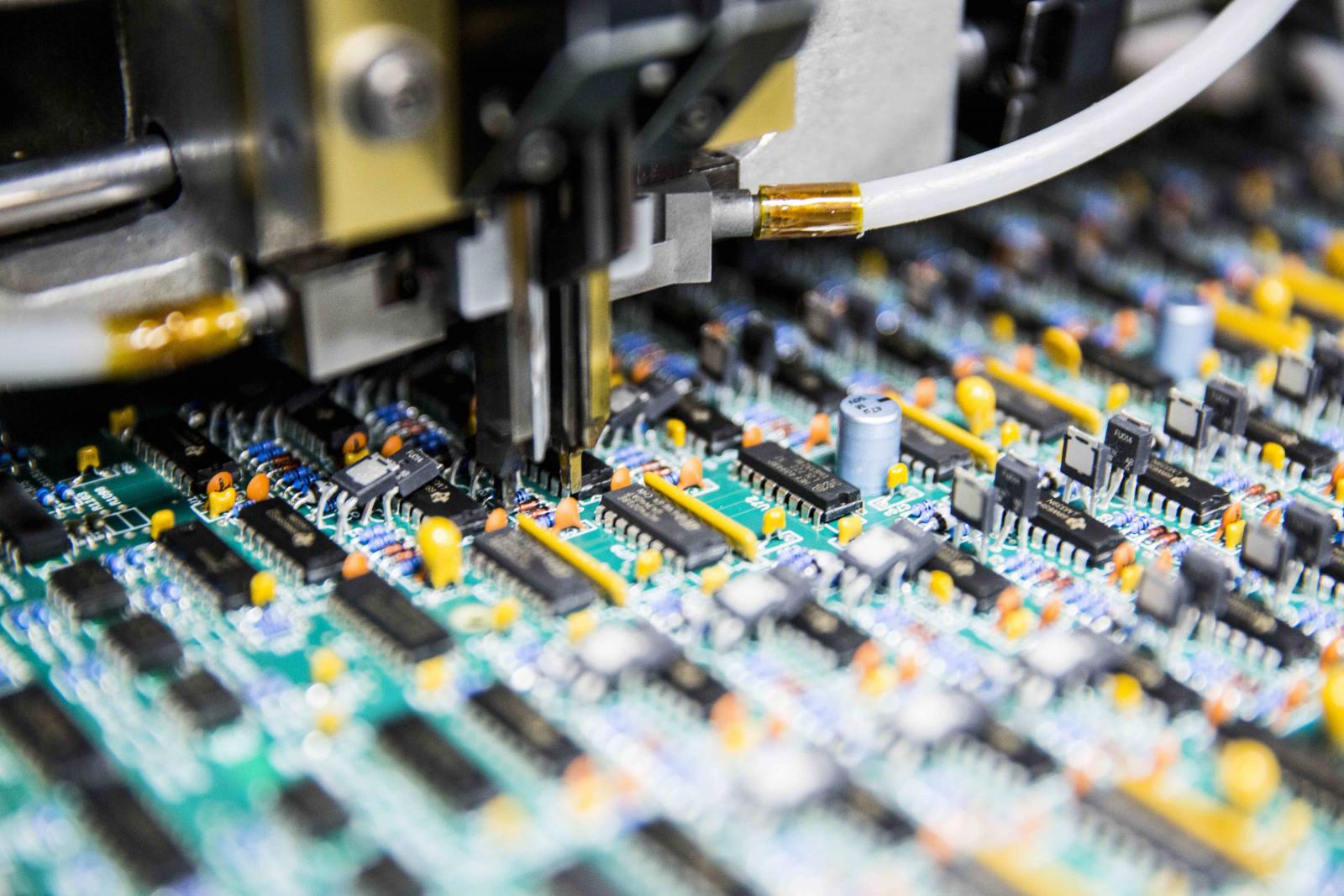

Electronics manufacturing and the machinery needed to achieve it tends to work on a large scale. A company buying, for example, a surface mount line, would be unlikely to use its full capacity. A far better idea would be to sub-contract out that portion of work to a CEM who has that capacity.

And a good CEM does more than just ‘follow orders’. For example, we are often presented with printed circuit board layouts that are over-engineered, expensive and difficult to produce. So, we offer a prototyping service that helps designers remove complexity and cost from a project.

The lowdown on Contract Electronics Manufacturing

A CEMs such as Offshore Electronics, that is purely a contract electronics manufacturer will have no products of its own; rather it makes other companies’ products as a manufacturing partner, specialising in industrial and scientific machinery, such as industrial controllers and medical equipment.

We recently invested more than £500,000 to expand our capabilities, including a new surface mount production line with screen printer, precision placement machines and reflow oven capable of up to 56,000 placements per hour. The new line complements two existing lines, giving the company extensive production capacity.

Compliance is a huge learning curve, and achieving an ISO-approved facility like the one operated by Offshore Electronics takes time and money; the company works to IPC 610 Class 3, which is considered the ‘gold standard’ of electronics assembly.