Erodex has supplied Krohne with a carbon fibre composite graphite fixture for the UK’s largest horizontal vacuum brazing furnace.

Krohne is a leading manufacturer and supplier of industrial process instrumentation, and its UK operation in Wellingborough is the company’s global centre of excellence for Coriolis mass flowmeter technology and where it manufacturers its award-winning Optimass mass flowmeters.

This involves working with specialist materials such as Duplex 31803 and Super Duplex 32750 stainless steels where the brazing process is highly critical.

As the largest of Krohne’s products to be brazed are up to two metres in length, it has a problem that there was no suitable furnace in the UK with a hot zone large enough to process them. This meant that the brazing had to be subcontracted to a French company, which brought challenges with with lead times, transport, and associated cost issues.

Krohne Ltd’s decided to bring the brazing of its larger products in-house, thus ensuring complete control over quality and lead times, and invested in the UK’s largest horizontal vacuum furnace.

The company therefore needed assistance with the design and manufacture of a fixture that would possess the specific hot zone capability, be of appropriate size and at the same time cope with weight, cost and distortion limitations whilst processing these larger products and turned to Erodex UK.

Evolution of fixture design

Discussions started around six to nine months prior to when the furnace was due to arrive. The original concept design provided by the Erodex UK team was based around using graphite plates and spacers.

Following close consultation with their Krohne counterparts this was reviewed and it was determined that a flat grid method would be more suitable, due to strength requirements of the fixture and to enable the required reduction in fixture weight.

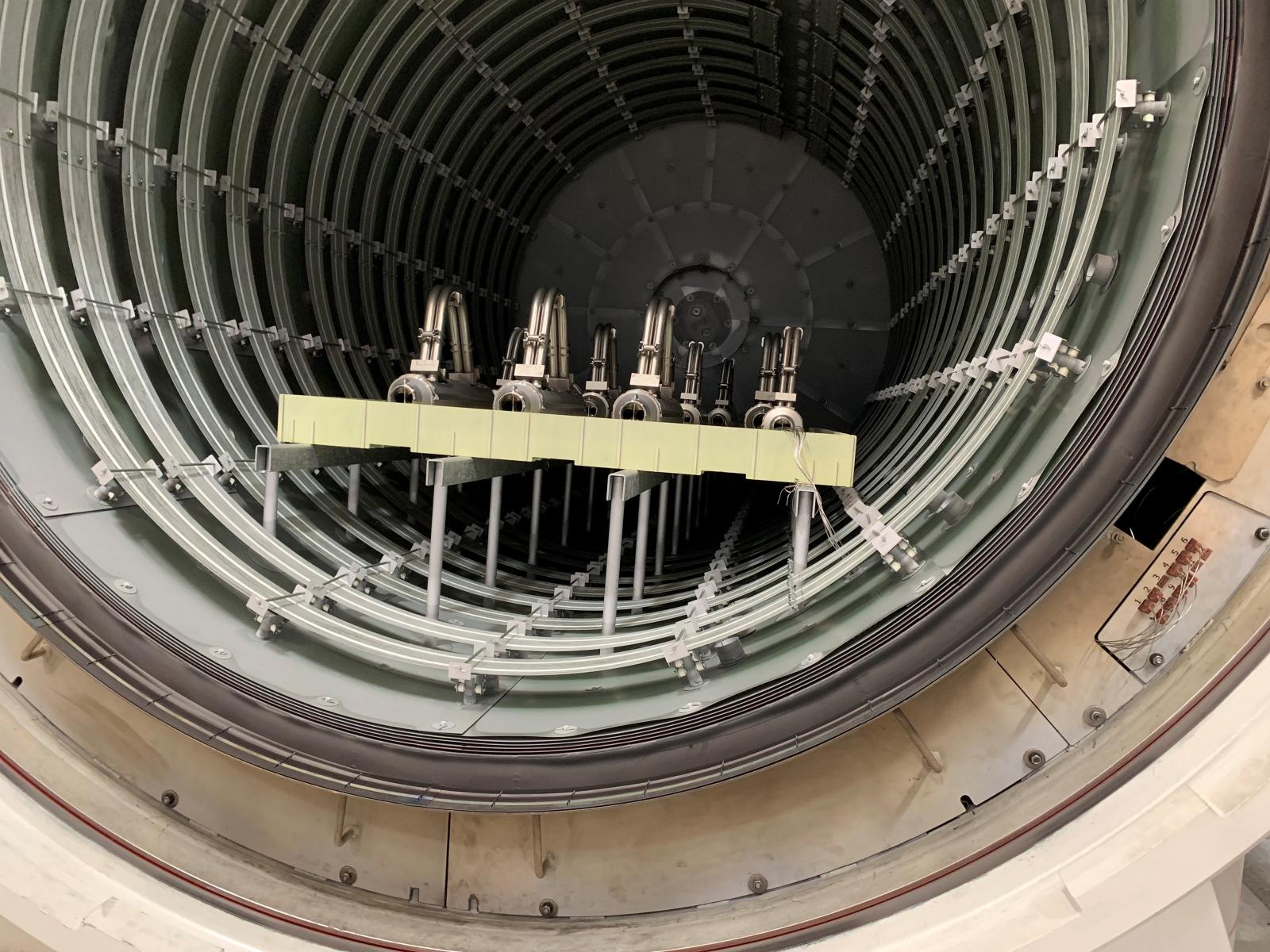

The resulting design was a 2.4m x 1.2m Carbon Fibre Composite (CFC) fixture consisting of two layers and a cover plate to ensure that there was no direct radiation heat onto the components processed on the top layer and that heat is evenly distributed within the furnace.

Production Engineering Manager Darren Hawes comments: “The Erodex team were able to understand our specific requirements and design a fixture based on a CFC grid. We then had a further meeting and added in channels and a cover plate that sits on top of the CFC grid structure to maintain 0.1mm flatness.

“Perforated holes were added to allow the 360-degree gas cooling to flow underneath the fixture to the parts, because cooling is one of the critical features of the process. Side rails were added to the fixture to remove the possibility of any parts falling off and we added lifting points to the fixture, so once removed from the furnace, if the loader were to break down at any point, the fixture could be removed from the loader by overhead cranes”.

Andrew McFarlane, Technical Sales Engineer at Erodex UK and project lead adds: “When it became clear that a more intricate and technical design was required, we involved our full High Temp team and further meetings took place to come up with the optimum design to incorporate the changes our customer identified and to deliver the additional required project features such as spares and changes to the spacers.

“We showed flexibility to provide what the customer wanted to achieve this and altered the designs until they were satisfied”.

Krohne Ltd Manufacturing Engineer Tom Harrison explains why, guided by the Erodex UK team, it opted for a Carbon Fibre Composite (CFC) graphite fixture: “We had to find the right material for the fixture when considering weight, cost and distortion limitations and we could not find another material that was comparable to CFC for achieving this.

“The CFC fixture is lightweight yet as the temperature increases within the furnace the material gets stronger. Our main requirement of the fixture and the plate itself was to have a 0.1mm flatness tolerance, so when we manufacture and process our parts, any distortion of the fixture does not impact on the assembly that is being processed.

“The straight tube assemblies being processed within the furnace also have a 1/600mm straightness tolerance. Up to two metres we can have 3mm distortion end to end in the bow of the tube. To get that right, we required the fixture base to be as true as possible, so that we are not adding any additional distortion into the processing of the parts. The CFC fixture was therefore designed and manufactured by Erodex to deliver on that 0.1mm flatness constraint.

“In addition, the more mass within the furnace, the greater the effect on heating and cooling rates. A metallic fixture can act as a heat sink, using CFC reduces the mass greatly so our process is optimised and the energy we do use is used efficiently”.

Additional benefits of using a CFC grid structure.

An added benefit of a CFC grid structure is that if individual parts of the fixture break, only these need to be replaced. This contrasts with a metallic grid, where the whole grid would need to be replaced or refurbished, resulting in a significant reduction in maintenance costs.

Furthermore, Duplex stainless steel and Super Duplex stainless steel are mainly used for corrosion resistance, meaning that any carbon or other contamination picked up from the fixture itself could affect the metallurgy of the material, which in turn can add further complications to the products being processed.

To avoid this, the CFC graphite fixture was coated in a Yttria Zirconia coating to prevent any carbon ingress into the material.

Hawes continues: “The knowledge of the application and properties of CFC within the Erodex UK team was vital in helping us to understand what could be achieved both with the material and the fixture design itself. As we moved through the process, the design became more complex, so having their expertise at hand to help develop this was very beneficial to us.

They acted like a partner on this project, and it was clear from the outset that they were willing to listen, accommodating changes and providing new ideas”.

Fixture assembly and operation

Erodex assembled the fixture prior to coating and provided a video demonstrating how this should be repeated. Following coating of the fixture, the team were back on site to reinforce this with demonstrations of the ease of assembly to all Krohne Ltd end users.

Hawes’ team need to make sure the fixture is precisely central within the furnace every time it is loaded. To achieve this, a specialist forklift is used and Erodex designed the fixture to be held by the forklift so that this was achievable. The forklift is centralised as you drive it into the furnace, by two guides that sit underneath it.

Harrison adds: “The fixture itself has been used now since October, we have completed numerous cycles and it is holding up to design requirements of flatness, the coating is performing well and ultimately, the fixture is achieving what it was required to do.

“We vacuum clean the fixture and furnace after every cycle to remove any debris coming from the processing. The fixture also goes through a maintenance check/ two weekly burnout to remove any contaminants that may have come onto the fixture because of the processing of the products in the furnace.

“We have also used the CFC graphite fixture to process a product as part of our furnace validation that was previously processed by a subcontractor. We could see that there was 7mm distortion end to end on the part provided by the subcontractor. Once we processed it through on the fixture all the contact points were then level again. We would have not been able to achieve that in a subcontract furnace.

“Ultimately, this has given us full control over processing. It has given us the capability to develop our processes and increase productivity and allows continuous development and improvement of the process too.

“For example, we had identified a few issues with how one cycle was run, where we were positioning the monitoring thermocouples to ensure the parts are fully up to temperature before we started the brazing part of the process, so it has given us further knowledge on that, which in turn has benefitted the product being processed”.