Doncasters Group unveiled a demonstration project for a fully electroformed one-piece leading-edge lip skin for a commercial aircraft engine at the Farnborough Air Show.

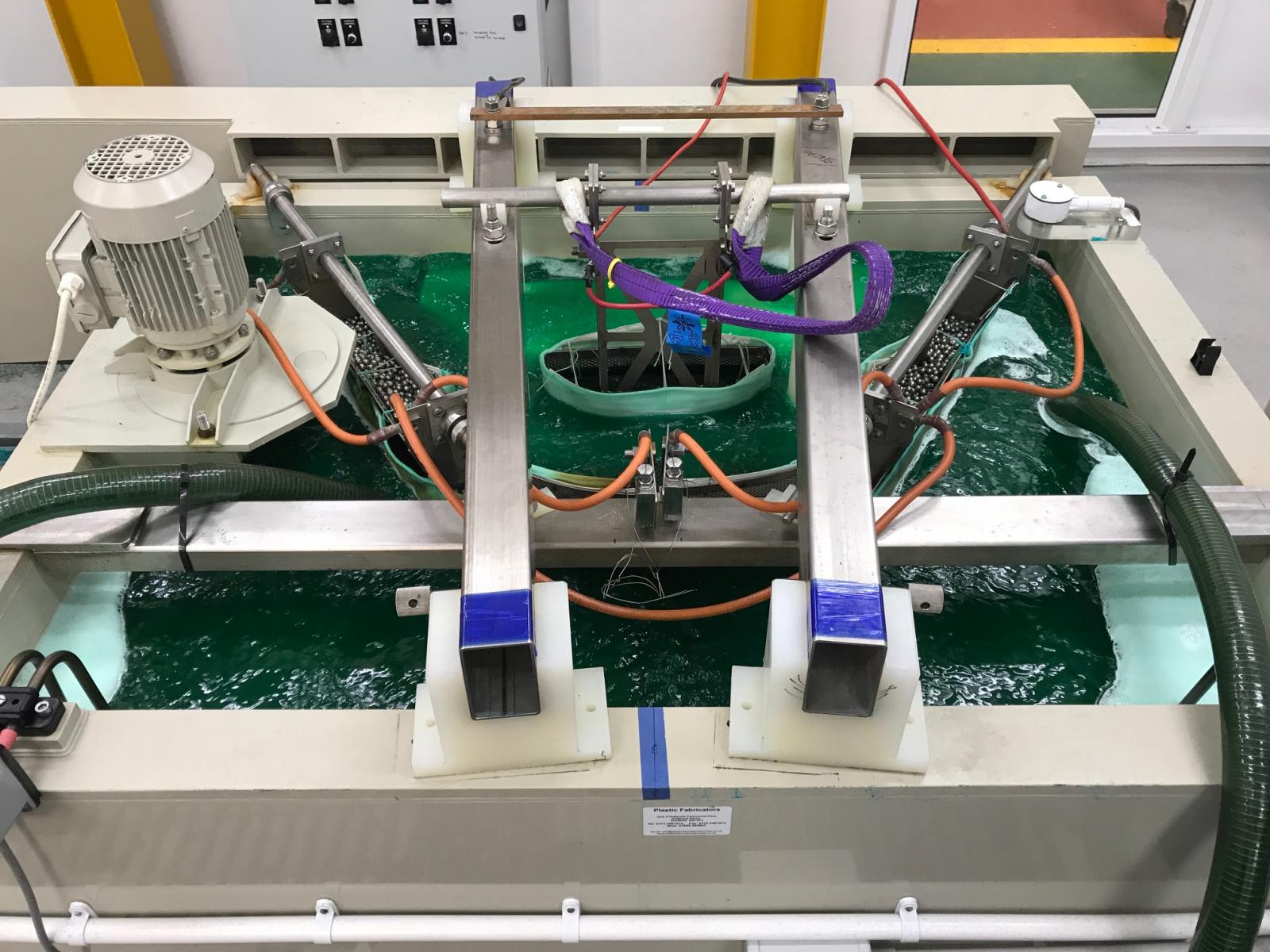

This would be applicable for a large regional or single aisle aircraft. Electroforming is a proven additive manufacturing process used to physically deposit metal in microscopic layers to highly precise geometries. While it is not a new technology, it has never been applied to an aerospace component of this scale. This new application is set to bring customers significant costs savings while also offering superior erosion properties.

Andrew Woods, Business Development Manager who spear-headed the electroformed demonstrator project commented: “We’re excited to be launching this industry first at Farnborough - it’s certainly going to grab people’s attention. Electroforming has so much potential for the aerospace industry and beyond, so we look forward to sharing our learnings with delegates at the show.”

The company’s recruitment team was also be on hand to promote next year’s graduate scheme and career opportunities as well as looking to find key talent to fill open roles in the company.

Tim Martin, Chief Commercial Officer, added: “There’s so much going on at Doncasters and throughout the aerospace industry, and we are privileged to be involved in this unprecedented market growth. We hope that our customers and any students visiting us in Farnborough this year will find something to be inspired by.”