During the first quarter of 2019, fifteen new members have joined the GTMA. They cover a wide range of technologies including mould and tool making, machine tools, automation, precision manufacturing and R & D.

GTMA CEO, Julia Moore, said: “We are delighted to welcome Fanuc, Filtermist, Morson Projects, R-Winter Tooling, National Composite Catapult Centre, Plazology, Surface Generation, IBS Precision Engineering, Surtec North East, Guhring, Tebis, Solent University, Ewikon, Consort Medical, and Park Sheet Metal into membership.

“Each company will, no doubt, have a different reason for joining GTMA, however, I believe that our digital marketing programme provides a key route to market for companies. It includes business profiles and is combined with our successful social media campaign to maximise every member’s media presence.

“Our successful events calendar, which includes the recently held Manufacturing UK event at Mazak, our forthcoming Business Breakfast Seminar at Fanuc at Ansty Park on 23rd May and the third year of our popular Manufacturing Solutions Ireland event on 12 June 2019, in Limerick, with over 100 exhibition stands and the visit of the British Ambassador indicative of our interesting network meetings available to members and industry alike.”

Julia Moore concludes: “We are in detailed discussions with a number of additional industry names and I am confident the ranks of the membership will swell even further in the coming months. Of course, the experienced and knowledgeable team at the GTMA will ensure that members and industry alike will receive support for their business and technical enquiries as they require.”

New Members in Brief

Fanuc provides industrial automation solutions - from the supply of CNC controllers, lasers, robots, machining centres, EDM and injection moulding machines to the complete integration of factory automation systems; providing a single customer support portal for these three core businesses.

Filtermist’s ethos is to protect people by ensuring cleaner, safer, more productive workshops. The company designs, manufactures and installs industrial air extraction and filtration solutions, including the provision of maintenance contracts and LEV services. The company also distributes a range of process fluid filtration consumables and coolant control equipment throughout the UK.

With over 700 employees, Morson Projects provides cost-effective multi-disciplined management, engineering and design services to clients in the most demanding industrial sectors including nuclear, aerospace and energy. Its team provides solutions ranging from full turnkey projects to individual component design and analysis, with a proven track record in delivering these services to many blue-chip clients.

R-Winter Tooling is a modern design and engineering business based in Rochester, Kent. The company specialises in machining a broad spectrum of materials including aluminium, mild and stainless steel, tool steel to 62 HRc, plastics, PU and epoxy tooling boards, composites and carbon fibre. Designing and manufacturing both large and small tooling systems, checking and assembly fixtures for the automotive, aerospace and renewable energy industries.

From an impressive facility near Bristol the National Composites Centre (NCC) aims to accelerate the growth of UK industrial output by enabling design and manufacturing enterprises to deliver winning solutions in the application of composites.

Plazology is a consultancy for injection moulding technical support. One of the UK’s leading injection moulding simulation providers it assists in the development and production of moulded components for high quality, consistent parts; shorter cycle times; quicker production roll out, and reduced costs.

Surface Generation was established to develop and commercialise its Production to Functional Specification (PtFS) technology. Its customers use PtFS to optimise the use of advanced composite materials to manufacture products such as aircraft wings, consumer devices or automotive components much more efficiently than is possible with traditional manufacturing techniques. PtFS enables a paradigm shift in cost, quality and delivery that provides fast (up to 95% lower cycle time) and energy efficient (up to 95% less) solutions to the world’s manufacturing OEMs and material suppliers.

IBS Precision Engineering’s products and custom solutions can be found in leading companies world-wide serving industries from disk drive to semiconductor equipment, printing and medical systems. In the field of machine tools both builders and users are supported with measurement systems delivering significant bottom-line productivity improvements.

Surtec North East is a press toolmaking and precision engineering company that offers a variety of CNC machining service. Providing a complete service from in-house design facility, to manufacture and beyond, Surtec North East is able to provide a bespoke service to all its customers, with a highly skilled and qualified team.

Guhring is a world class manufacturer of precision cutting tools and allied tooling for the engineering and manufacturing industries. Tools can be selected from the vast standard, stocked Guhring range or manufactured to suit customers specifications and supplied throughout the UK and Ireland.

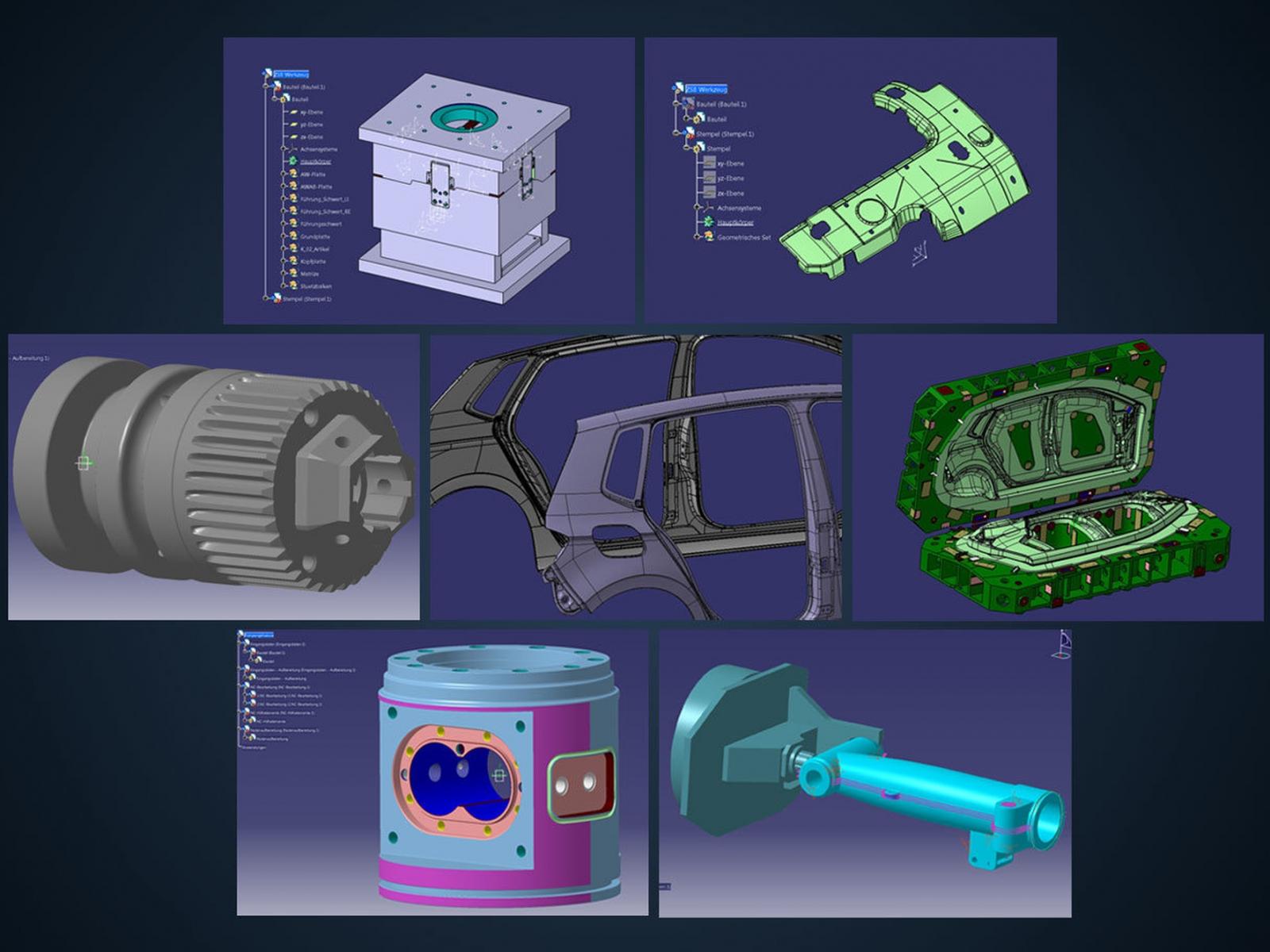

For over 30 years, Tebis CAD/CAM software has ensured process efficiency and a technological edge in the die, mould and model manufacturing sector, in industrial design and in precision machining and manufacturing equipment.

Solent University is a comprehensive University offering programmes across five academic Schools, including the School of Art, Design and Fashion; Business, Law and Communications; Media Arts and Technology; Sport, Health and Social Sciences and through its Warsash School of Maritime Science and Engineering. Solent's maritime courses have been ranked among the best in the world.

For nearly 40 years, Ewikon has been a synonym for innovative, reliable and practical hot-runner technology at the highest technical level. Its system solutions optimise the injection moulding process, enhance the quality of the manufactured parts, reduce costs and have proven their capability in thousands of successfully realised projects for all sectors of the plastics processing industry.

Consort Medical is a leading global contract development and manufacturing organisation providing advanced delivery technologies, formulation and manufacturing solutions for drugs. The Group is at the leading edge of innovation and is committed to investing in patient and customer driven innovation, with the potential to create new treatments, new markets and new opportunities.

Park Sheet Metal is a privately-owned company supplying metal components and assemblies to the automotive, defence and aerospace industries. Based in Coventry, on five sites with a total floor space of 85,000 ft2, using state-of-the-art equipment and production methods. The business has a reputation as a world-class automotive supplier. Customers include Aston Martin, Bentley, BMW, Jaguar, Land Rover, Lotus, Nissan and Volvo as well as other well-known blue-chip companies.

Picture: Tebis CAD/CAM software

BACK TO ENGINEERING CAPACITY NEWS PAGE