Cleanroom thermoforming can offer ideal packaging solutions for medical devices, writes Todd McDonald, Director of Sales & Marketing at TEQ

The world continues to witness a rapid development in technological brilliance but what must not be overlooked is that the importance of protecting that technology becomes increasingly vital.

Improvements to packaging design are now a necessity. At the same time, there is a demand to deliver products in a packaging solution that adheres to strict specifications while using less production energy and material as well as faster production times.

So, what is thermoforming?

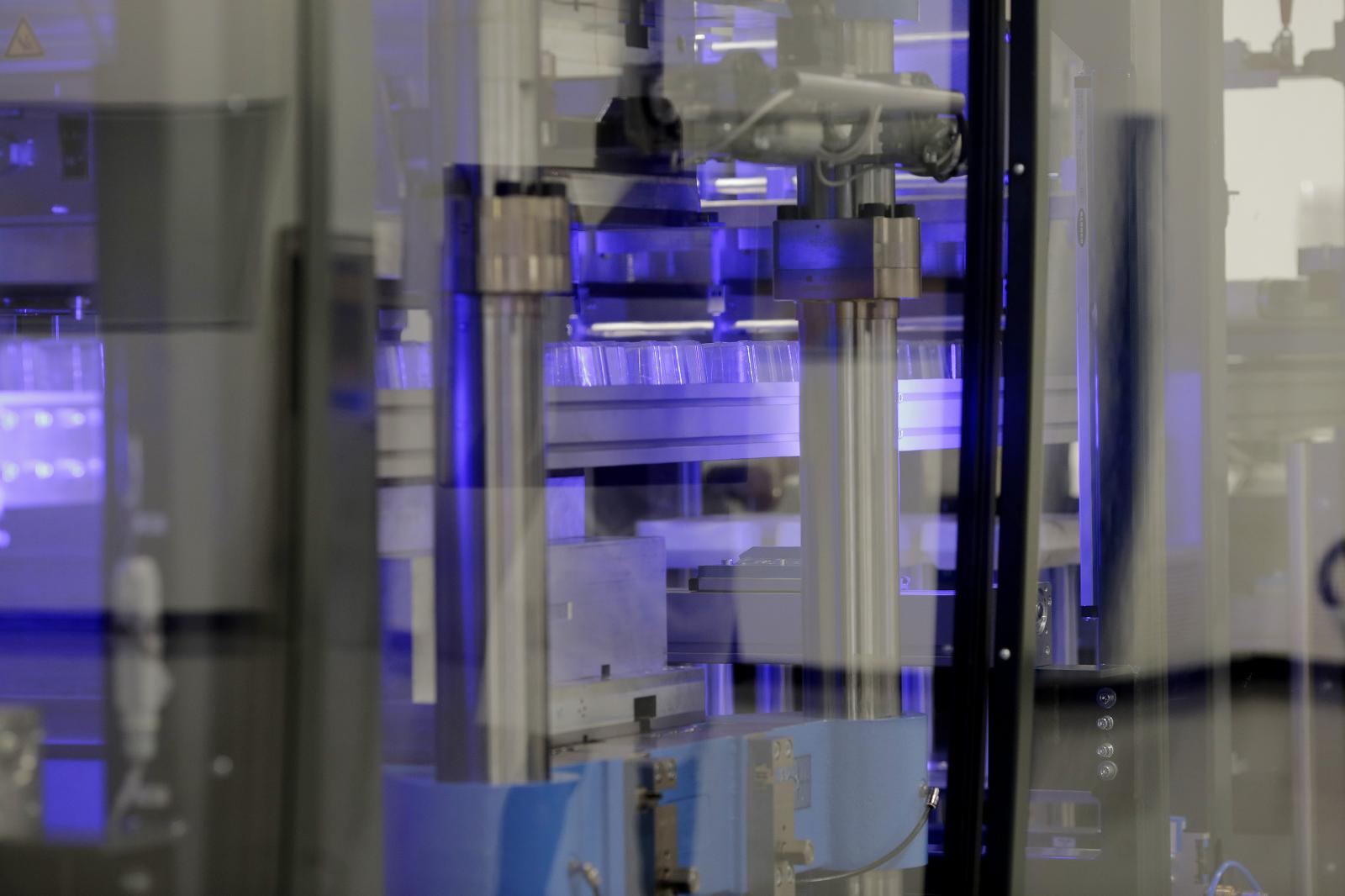

Cleanroom thermoforming is widely used for the production and packaging of pharmaceuticals and medical equipment.

This method of thermoforming is carried out in an ISO certified cleanroom meaning any particulates circulating in the air are kept to a minimum.

Thermoform packaging is extensively used to safeguard sterile instruments and implants. This packaging method permits the use of lightweight, clear plastic enclosures that stop microbial and dust particles from contaminating the sterile item.

They also make possible the product’s secure storage for lengthy periods whilst maintaining the sterile environment.

The benefits of thermoforming

This advanced technology has established itself as a preferred option for many industries and applications, including medical devices, with the main benefit of this packaging solution the clear cost efficiency it offers. The stiffness of this type of packaging material also allows for the creation of smaller units and space-saving benefits. The stiff packaging also offers a barrier to odours and resistance to oil and grease.

Packaging from cleanroom thermoforming also has the capacity to offer advanced protection of medical devices and the importance of this cannot be underestimated as the packaging of medical devices is as important as the product itself. Once the packaging’s integrity is compromised, sterility is lost and the device is ruined. This is why thermoforming is an ideal solution.

Thermoformed plastic packaging can offer several other advantages including:

Product Orientation: A nurse may need to quickly confirm a product’s orientation and how to grab it. With a thermoformed tray, a nurse can be sure that the medical device stays securely in place in the intended location so he/she can remove it swiftly and confidently.

Handling Assurance: To ensure a device doesn’t compromise sterility, a nurse needs to control the movement of a device as its package is opened. A thermoformed package is more likely to ensure there is no unnecessary rotation or accidental removal.

Clarity: A nurse can find it beneficial to see and identify the product clearly so he/she can better present the device or see any potential defects.

Consistent Opening Experience: Incorporating a good peal area in the package design can allow a nurse an easy access point for pealing the lidding back from the package.

Additional Protection: With rigid plastic, a medical device is protected in sensitive device areas. For example, a package can be designed so a syringe will not get depressed.

More Ergonomic: A pouch can require both wrists to twist to open, putting repetitive strain on both of the nurse’s wrists. With a sealed thermoformed tray, only one hand is opening the seal while the other is holding the tray in place.

Impact of COVID-19 Pandemic

There are clear signs that the COVID-19 Pandemic is having a significant impact on the design and manufacture of medical devices, equipment and implants.

In these uncertain times medical manufacturers have had to ramp up production to meet heightened customer demand.

Cleanrooms have firmly established themselves as an integral part of the production process as cleanliness can be guaranteed in their controlled and sterile environment, preventing potential contamination caused by bacteria or air pollutants.

Companies that make medical devices and the packaging for them have to meet the most stringent regulations from various organisations.

One of them is The ISO (International Organisation for Standardization) which consists of a group of non-governmental bodies operating in 164 countries. It is entrusted with the power to enforce exacting standards for a range of commercial markets.

In 2016 it published the latest edition of its ISO 13485 which sets out to ensure patient safety by the regulation of hygiene and contamination control in medical product development.

It is generally recognised that the main hurdle to overcome when designing cleanrooms is their ability to deal with any air pollutants. Filtration units are used by manufacturers to control airflow and stop airborne particles larger than a pre-defined size from entering. A range of devices can make this happen such as ionisers, carbon filters and non-filter purifiers.

Another approach to preventing cleanroom contamination is by providing a high standard of training for staff and ensuring they wear correct PPE such as gowns, hairnets and overshoes.

Manufacturers are also advised to keep correct supplies and equipment in clean spaces and, where appropriate, dispose of or sterilise them. Regular risk assessments ensure ongoing improvements can be made to foil any new contamination threats triggered by ever evolving technologies.

One thing is for certain, continued innovation and the advance in technology in the medical sector brings with it unlimited potential.

Manufacturers will face the same pressures to cut costs and be even more efficient by introducing more automation on the assembly line, utilising the likes of robots and smart testing. AI and machine learning can also expect to play a role by boosting quality standards and early detection of any issues.

New developments and a move towards more complicated products such as nanotechnologies and the miniaturisation of devices are another new challenge that has to be faced by manufacturers in an increasingly competitive sector.