Doncaster-based Onesite (Laser) Ltd has grown to become a leader in the supply of laser cut and formed parts and has now added laser marking to its capabilities.

Originally a subsidiary of Onesite Solutions Limited, a service provider to the access engineering industry, Onesite Laser began trading autonomously in April 2010 to address growing customer needs for precision laser cut components.

Onesite Laser recently moved into a new 10,000 square foot facility. Here it operates two recently purchased Trumpf laser cutting machines with the intention of installing a third one soon. These Trumpf TruLaser 3030 fiber machines, with a working range of 3000 x 1500 x 115mm and laser power of 6000 watts, is capable of working mild steel in all sheet thicknesses.

The TruLaser 3030 fiber works with a fully integrated solid-state Trumpf TruDisk laser rather than the CO2 lasers the company had previously used.

“Going from a CO2 machine to a fiber was like driving a different car, from an automatic to a manual,” says Managing Director Shaun Simpson. “You have to re-educate your operators, your material source, your programming, and if you get any bit wrong, it ends up being disastrous. We learnt the hard way, like many laser cutters, as we expected it to be the same but it wasn’t.” But as Shaun explains, once they all learnt how to drive the fiber machines properly, there hasn’t been a single complaint from the operators.

One of the biggest benefits of the TruLaser 3030 fiber machines is its ability to operate at both higher speeds and with higher electrical efficiency, resulting in lower running costs. “Our electricity bill has halved,” admits Shaun Simpson. “We built the new facility with three CO2 laser machines in mind but with the two fiber machines we’ve not needed to purchase a third yet because the technology is reliable, stable and it’s much quicker than what we expected it was going to be.”

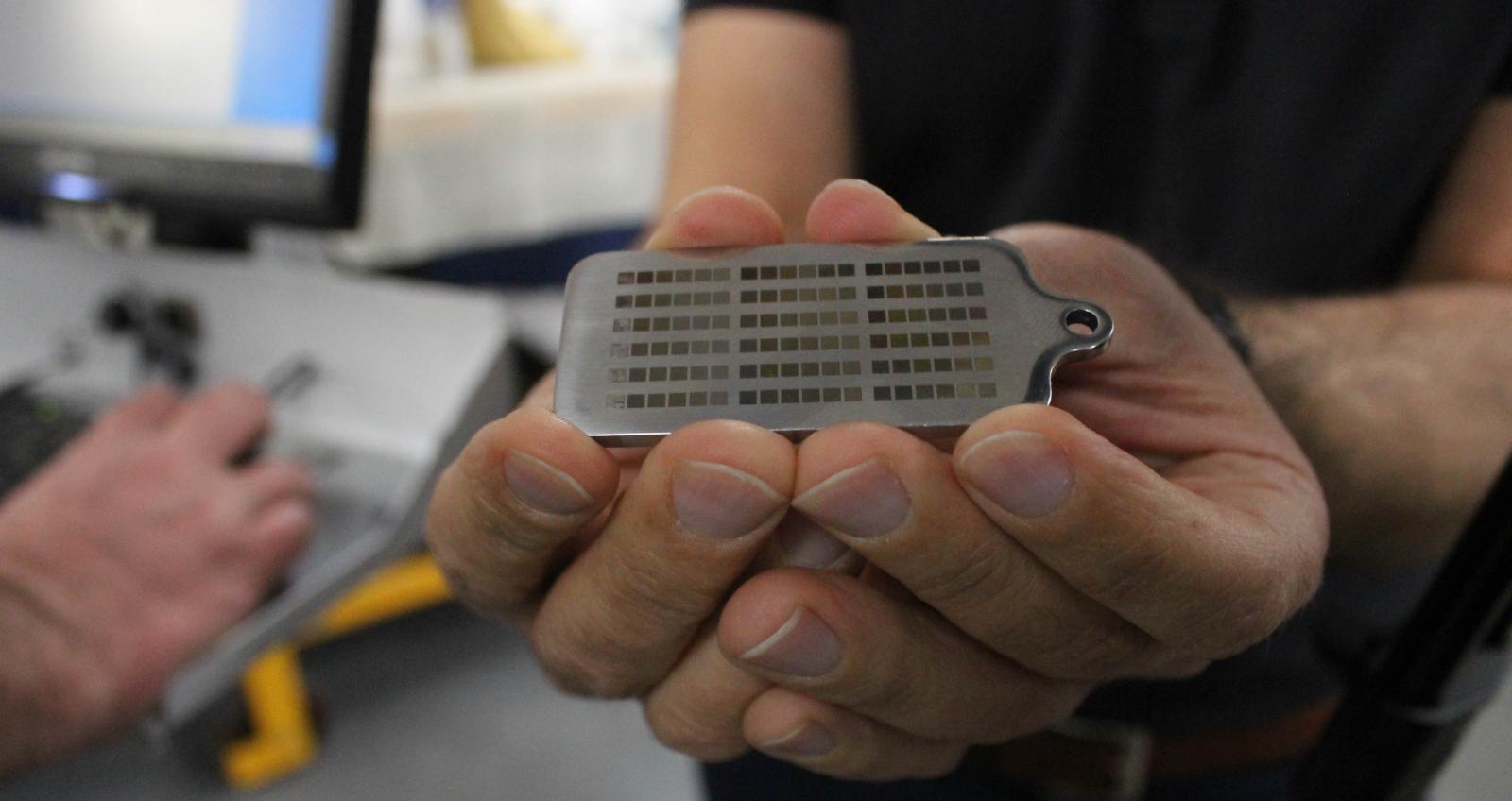

In the new facility, Onesite Laser has also invested in another new machine, the Trumpf TruMark Station 5000. This marking system, which is suitable for diverse application scenarios, was not originally purchased for commercial gain. “It was bought to try and get my youngest son interested in engineering,” says Shaun Simpson. “We started by making little marketing trinkets like key rings, bottle openers and coasters. But as we used it more, we started to see the value in its use for commercial purposes especially as a lot of customers have seen what this little marker can do. We are developing it more and more for use for things like tags and deep engraving.”