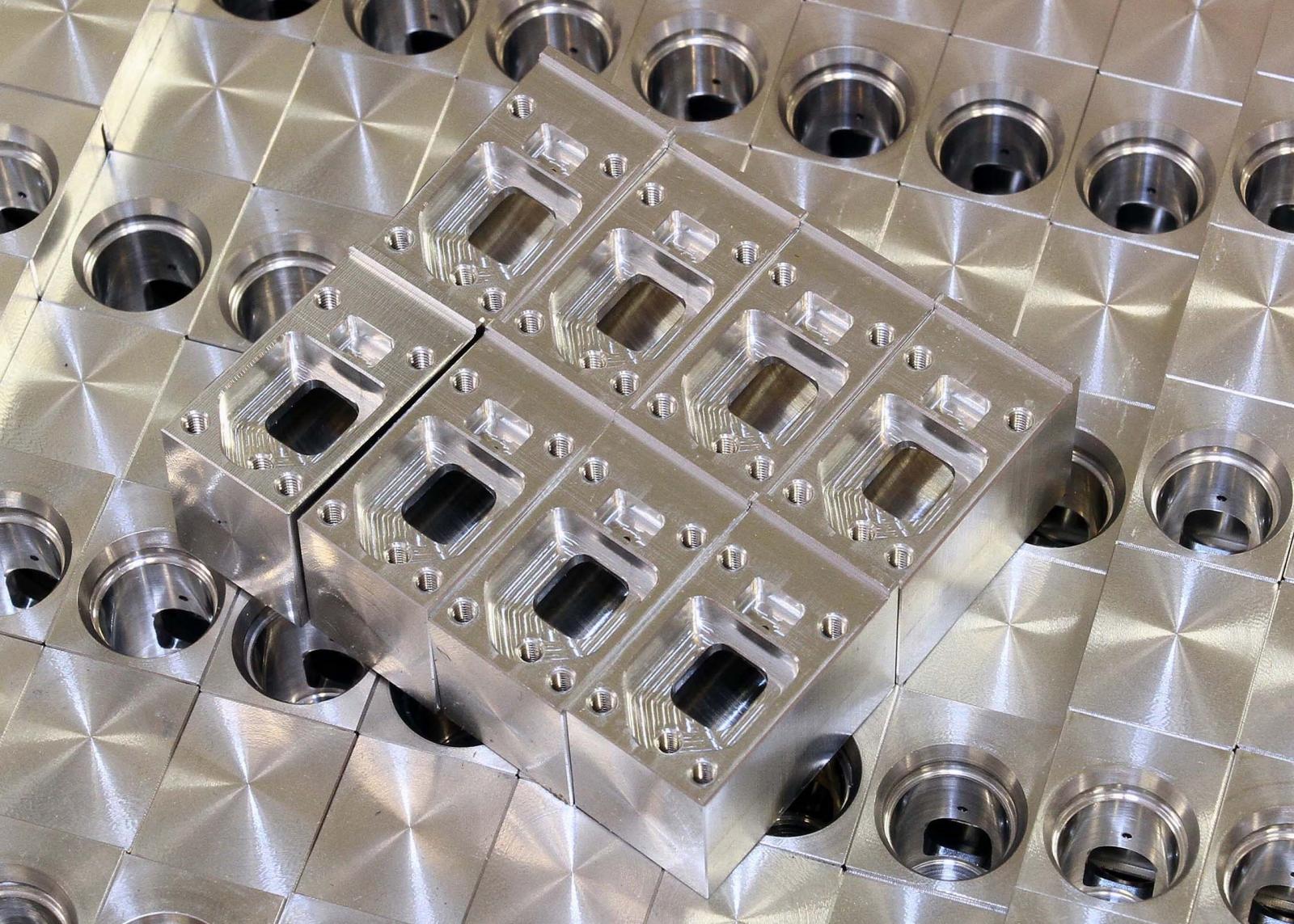

Looking at the cuboid aluminium components produced for medical diagnostic equipment by subcontractor AES Precision Engineering, one would think they were milled, drilled and tapped on a machining centre rather than a lathe.

Until April this year they were produced from sawn billet in two separate operations on a pair of 3-axis vertical-spindle machines in a total cycle time of 12 minutes.

Since then they have been machined complete from round bar in one operation in an Italian-built Biglia B565-YS 6-axis turn-mill centre supplied by UK agent Whitehouse Machine Tools.

Program run time has more than halved to 5.5 minutes, accuracy is improved and there is no handling between machines or work-in-progress on the shop floor, significantly reducing the cost of production. Only two turning tools are in the 12-station turret for facing the bar end and for parting off, the remainder being axial and radial driven tools.

Mark Wilson, a director of the family-run subcontracting firm commented, “We have been making these parts for years, during which time the volume has gradually increased to 1,000 per month. So we needed to find a more efficient way of machining them.”

Production engineer Trevor Orman added: “Although tolerances on the medical part are fairly open at 0.1 mm, the Biglia repeats to within microns, which means we no longer have to chase tolerance all day as the temperature varies on the shop floor.

“The machine’s accuracy will also be invaluable for production of more tightly toleranced components and its rigidity means that tool wear is noticeably lower than on our other lathes.”

The existence of the turn-mill machine has already brought in a new contract for the manufacture of 316 stainless steel automotive components that AES Precision Engineering could not have quoted for previously.

The subcontractor intends to transfer jobs from other lathes to the Biglia to enable more economical production. It is also looking for further bar auto work to a maximum of 70 mm diameter by up to 560 mm long, preferably involving runs above 1,000-off, to fill the machine’s capacity.

Founded in 1987 initially to manufacture components for the medical industry, AES Precision Engineering has since expanded into the automotive, leisure, marine, cosmetics and defence sectors, including the production of complex parts for drones and reverse-engineering of replacement parts for production lines. In 2004 it moved to the present, larger premises on the New Street Farm estate in Ashford, Kent and has invested heavily over the years in a range of new machining centres, including 5-axis models, and multi-axis CNC lathes.