New presses, software, monitoring systems and self-locking wedge clamps are just some of the highlights that visitors can expect to see when the largest ever Metalworking Village hits MACH 2020 in April (20-24th).

The Metalforming Machinery Makers’ Association (MMMA), which is the only organisation dedicated to the UK sheet metal forming industry, has capped a major year of growth by taking over 650 square metres of space at the event, allowing more than 26 members to showcase their services and technology.

Visitors will be able to enjoy live demonstrations of machinery and take part in technical discussions that will help them improve production processes, remove bottlenecks, whilst also increasing orders and profitability.

“Our members have reported a very strong start to 2020 following the Election result in December, with strong order books and a good pipeline of new opportunities across automotive, aerospace, construction, medical and renewables,” explained Adrian Haller, Chairman of the MMMA.

“This optimism has been reflected in the fact that we will have our largest ever Metalworking Village since we first started exhibiting over twenty years ago. There will be new technology, machinery and software on display, not to mention the unique opportunity to debate key issues, such as future skills and how we embrace the Internet of Things (IoT).”

He continued: “I’m especially delighted to see OSA Systems, QualiMach and Raybould Machine Tools, our three newest MMMA members, taking part this year.”

MACH 2020 highlights, include:

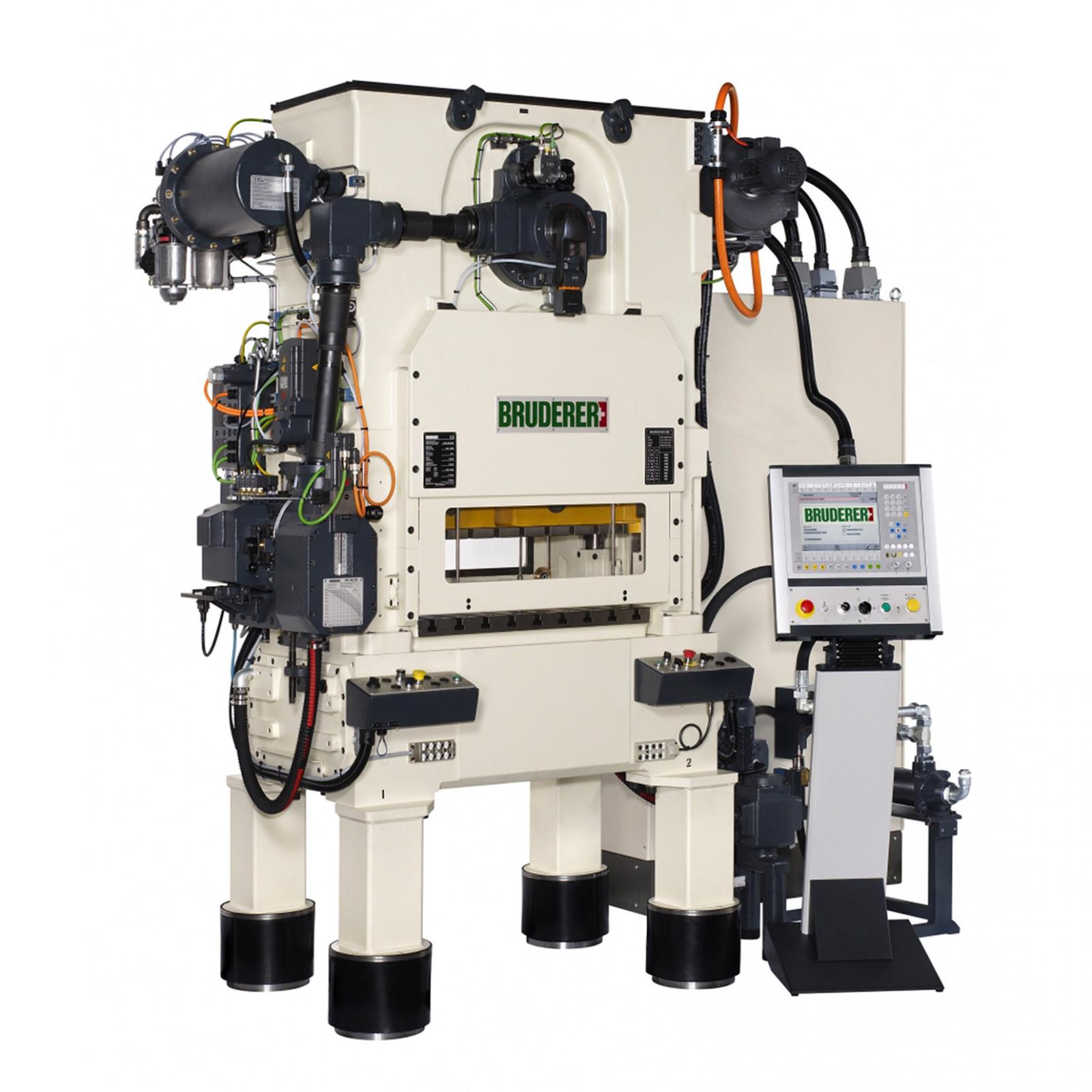

- Bruderer: A BSTA 280-75B2 high-speed stamping press, fitted with a BSV75 servo feeder and BPG planetary gearbox

- Decade monitoring Systems: Curve monitoring, which allows monitoring of the complete press cycle

- HELM: PTM, TSM Simlive tonnage simulation software and 4 channel module with anybus communication

- PressCare: New range of hydraulic, high speed and bespoke press lines from VAPTECH

- Press Form Machinery: New 2233 COMBO horizontal-decoiler straightener

- Press Techniques: Increase capacity and range of low-profile presses

- Raybould Machine Tools: New range of BOXIN mechanical power presses and HONG-ER press feeding and coil handling

- Roemheld UK: New ranges of die carts (500-1600kg), self-locking wedge clamps for press and mould and a new die handling catalogue

- Worcester Presses: New Titan Press, with adjustable stroke

The Metalforming Machinery Markers’ Association was originally formed in 1949 as the British Power Press Machinery Association, changing its name to the MMMA in 1971 to reflect industry demand.

Its main objective is to promote the interests of companies involved in the manufacture and sale of metalforming machinery and ancillary products, including high speed presses, hydraulic presses, straight side presses, manual die clamping, coil handling lines, servo forming, benders and stackers.

The organisation, which appointed Pete Waterman OBE as its first honorary member last year, provides advice, guidance and support on a host of issues, ranging from employment law and health and safety to securing reduced insurance premiums and international trade.

Adrian continued: “The MMMA has really gone from strength to strength over the last twelve months and now boasts a UK membership of 44 companies - the largest in our history.

“There is a lot more focus on listening to and reacting to the sector’s needs. One example is skills, with a lot of our firms struggling to fill key positions and this was holding back their growth.”

He concluded: “We responded immediately by inviting recruitment specialists to join our service offering and they are now helping members identify skill needs and, importantly, find the right qualified people for the roles.”

BACK TO ENGINEERING CAPACITY NEWS PAGE