Advanced multi-sensor metrology is giving Adwin Spring’s customers more accurate parts more quickly.

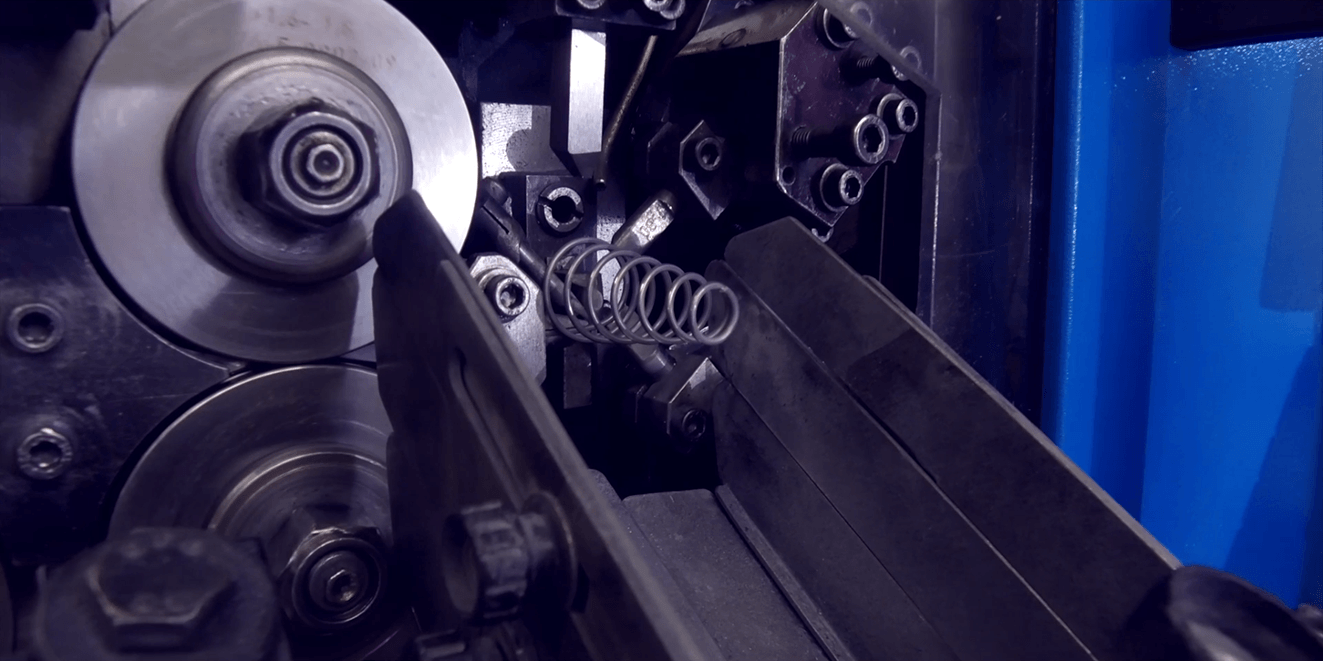

Adwin Spring Co produces prototypes in both wire and flat materials, catering for a diverse client base - including some of the world’s largest companies - in both short-batch and large-volume productions.

However, when it found that traditional part-measurement methods were no longer fully satisfying the speed or accuracy needs of its growing customer base, it turned Derbyshire-based OGP UK to help address the challenge.

Part of the Carfulan Group, OGP UK’s range of advanced optical and multi-sensor SmartScope systems can gauge the characteristics of even the most complex parts quickly and without human error, leading to better quality, reduced scrap and increased throughput.

Will Hayes, Quality Manager at West Bromwich-based Adwin, said: “Before we purchased the OGP we used traditional measuring methods of Vernier calipers, micrometers and shadowgraphs.

“With a lot of those methods you can get different people getting different readings that can be quite inaccurate.

“We were looking for an alternative method because our customers were demanding more accurate results as well as different types of reports and feature sets to what we were traditionally using, as well as 3D measurements.

“So we looked into different methods such as laser scanning and other non-contact companies, but found OGP UK to offer the best product.

“We needed a non-contact form of measurement as a traditional CMM would move the springs instead of making a definite assessment.”

Backed by intuitive and simple-to-operate software, the OGP CNC 300 machine purchased by Adwin utilises a high-quality auto-calibrating camera and supports a combination of touch probes, micro probes and laser scanners.

It is designed for use on the shop floor and, across a multitude of industry applications, collects detailed data quickly, precisely, reliably and automatically.

Working with more accurate and real-time statistics, from a single reference point, means tighter control of production processes, as any issues can be identified and remedied immediately.

Mr Hayes said: “During the demo stage we realised that the OGP interface was more suited to our business as we produce a large range of parts, so set-up and programme initialisation needed to be much quicker than most other machines because of the vast array of products we’re making.

“We started to see the benefits within the first month. A lot of our parts, as we’re doing process inspection, were programmed up very quickly and then the machine runs the programme in 30 seconds rather than the five minutes it took checking things on a shadowgraph.

“Other than a major improvement on process inspection and the time saved on writing reports and producing first-off inspections, it’s also drastically improved the quality of the product we send to our customers.

“It’s completely eliminated any sort of inaccuracies.”