Bowman Additive Production (Bowman AP) has significantly increased capacity by adding the latest HP Jet Fusion 4200 3D printer.

Coming 18 months after the launch of the venture, this will allow it to dramatically increase the size of their production 3D printing business and complements the company’s existing SLS 3D printer.

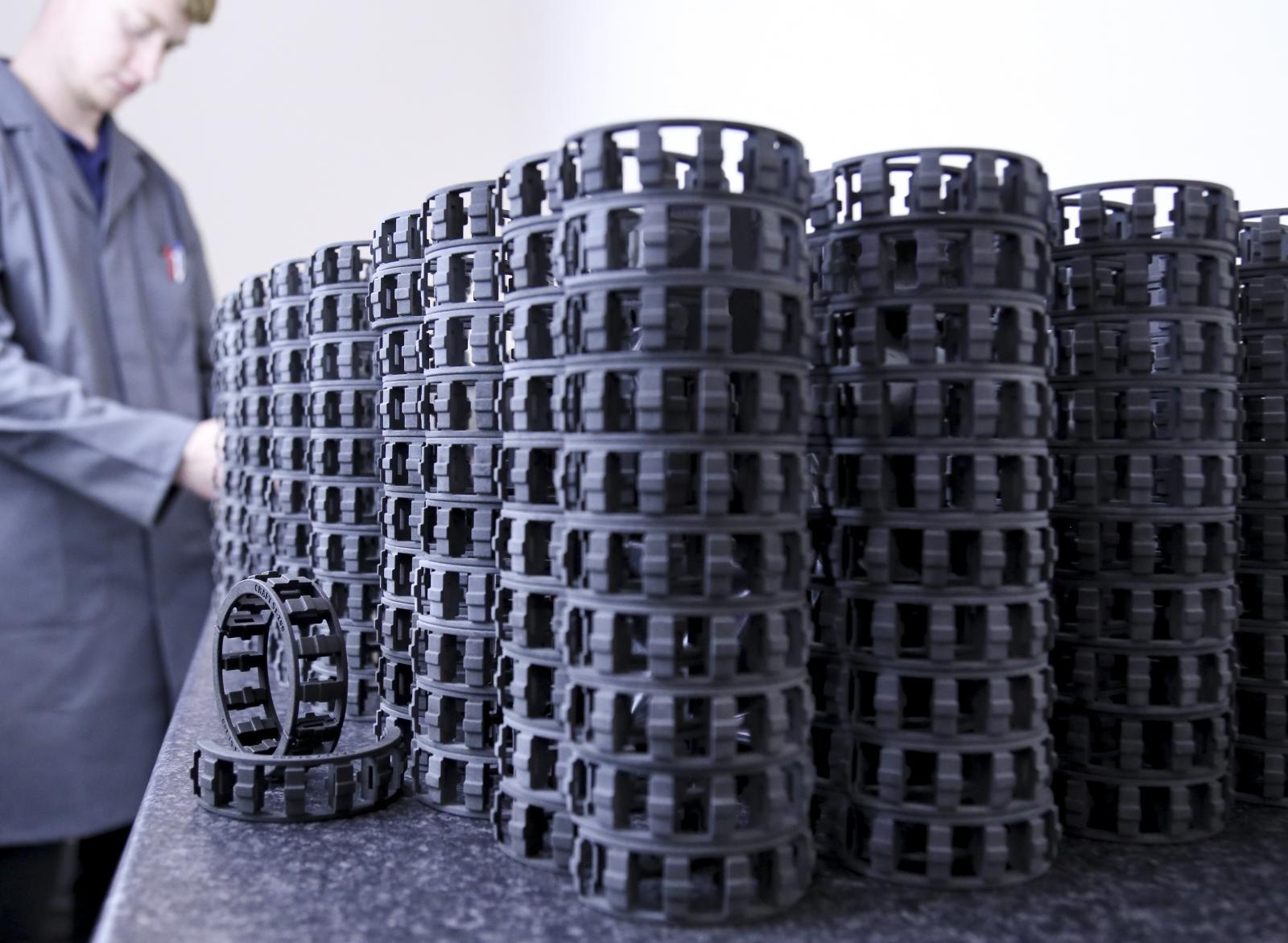

With this recent investment, Bowman AP will be able to offer their customers an abundance of benefits, including; significantly lower lead times, increased efficiency, better materials, online ordering, volume discounts and batch production.

As a part of this investment Bowman will be amongst the very first businesses in Europe able to offer customers the latest material from printing giant HP - HP 3D High Reusability PA11 material. Compared to the current industry standard PA12 material the new material has significantly superior strength, stiffness and flexibility. This is especially noticeable in the Z axis – while most 3D print methods result in vastly inferior properties in the vertical axis (between the layers of material from which the part is made) the HP Jet Fusion process results in near equal properties in all axis.

Bowman AP has also added 3D scanning capacity and invested in the latest DyeMansion Powersot S automated part finishing system to cement its place as an industry leading production 3D printing.

Bowman AP was established in 2016 with the aim of using 3D printing as a production process, rather than just a rapid prototyping service. It is exhibiting at Subcon on Stand A43