Following significant growth in its business, Cutting Edge Precision invested in a PSL Datatrack production control system to ensure that it could provide the administrative support required to provide a smooth service to this expanded customer base,

Cutting Edge (CE) Precision covers a range of markets from telecoms, special purpose machinery to gas and fluid control, medical equipment and automated welding machinery. Production of parts and assemblies in various quantities and materials is supported by a range of subcontract processes such as plating and painting, carried out by established partner companies.

It became apparent that whilst the capacity of the company's machines and equipment could deal with the challenge, its business administration spreadsheets were coming under considerable strain. Although they had worked for quite some time, there were many flaws. Not only were they very labour intensive to maintain, but the time taken to use and locate required information on any aspect of a customer's order was unacceptable.

Stuart Dunklin, Managing Director, recalls: “The greatest problem was that order and customer documentation was not linked in any way, resulting in information being frequently replicated, wasting a great deal of time and causing frustration. It was also proving difficult to delegate tasks.”

Stuart had been thinking for some time that the company needed a production control system that was user friendly and purpose designed for subcontract precision engineering. An industry colleague, who had been using PSL Datatrack for over 20 years, highly recommended the software.

Remote installation of the PSL Datatrack software and implementation was carried out in logical phases. One of the major issues was the fact that Stuart had a pivotal role in the day to day running of CE Precision and taking time out for installation/training was out of the question when the company was exceptionally busy. To address this, PSL Datatrack carried out web based training in bite size chunks so Stuart could continue to carry out essential production management duties alongside the implementation. “This proved to be an invaluable solution,” says Stuart, “the changeover to the new system was very smooth and PSL Datatrack demonstrated its ability to roll out in modules extremely efficiently.”

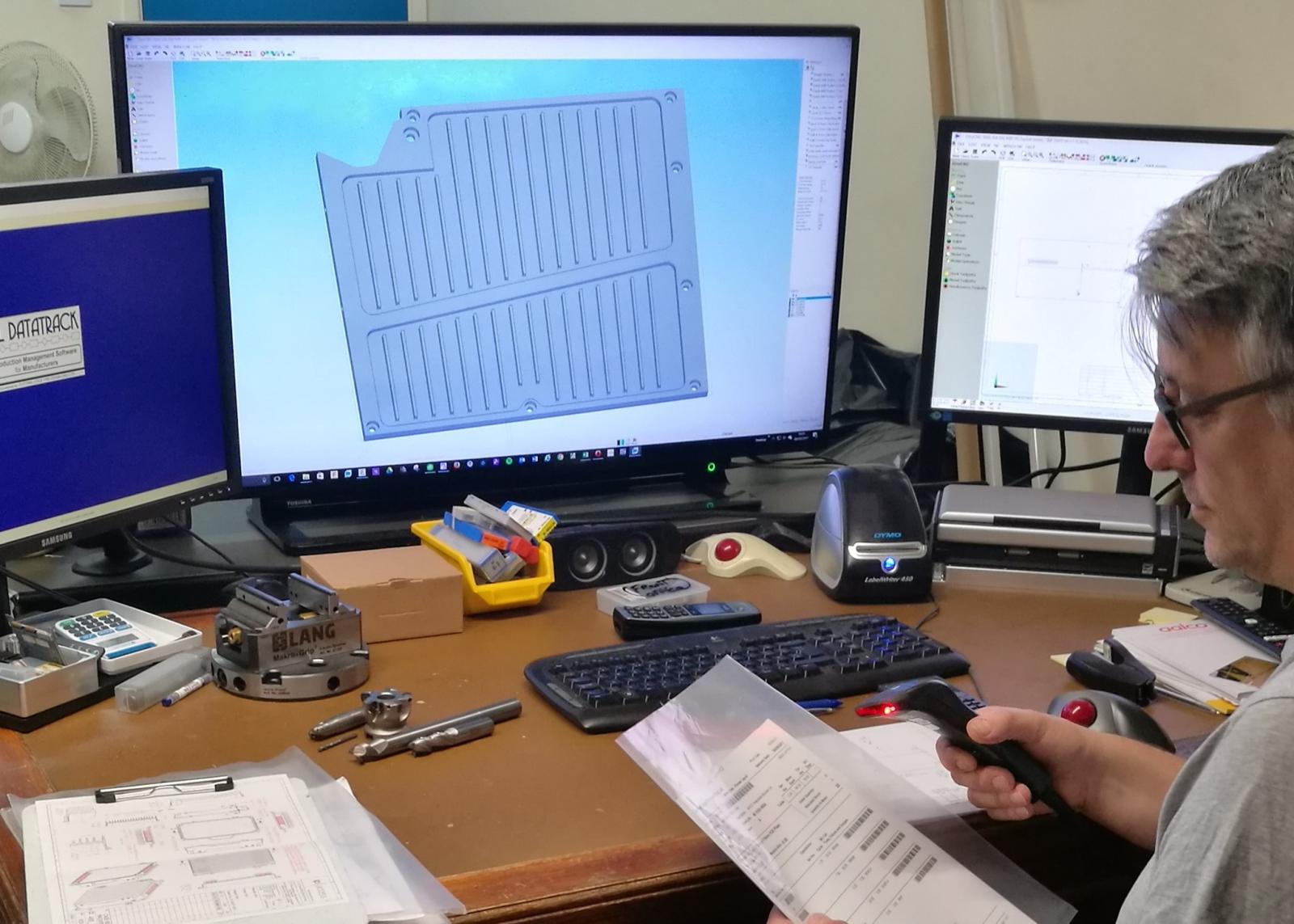

CE Precision wanted the PSL Datatrack system for managing the generation of customer quotations, recording material purchases, managing stock control, providing traceability and generating high quality supplier/customer documentation that looked professional and reflected CE Precision's quality. “Installing the PSL Datatrack software was a move that I felt would help show our professionalism and assist in moving forward as a business.” says Stuart.

Since its installation, PSL Datatrack has had a significant impact on day to day production management. Stuart recognises that the system has not only freed up his time, but has also made individual customer orders easier to process and information more readily available to everyone who needs it.

“Most importantly our customers are thrilled to see us moving forward and feel more confident in our ability to provide concise, accurate and professional documentation and to keep track of exactly what’s happening with their orders.” says Stuart.