William Hughes has come to the aid of a leading automotive tier-one seat manufacturer by applying its broad set of skills and advanced capabilities in the production of complex wire forms.

The order, which was for seat frames and trim wires, comprised a number of different complex parts, all of which would see use in five different vehicles types, including SUVs and saloons. In addition to bending and forming, several of the frames also required welding. The accuracy demands were such that engineers used 3D scanners and Vernier calipers to ensure the parts precisely matched the customer specifications.

“Although we had won the order a few months previously, and had turned round the prototype parts in just four weeks” explains George Cairns at William Hughes, “the customer hit a scheduling snag, which ended up with us having a very short time period in which to produce the first thousand pieces. These had to be delivered on time to ensure the product milestones were achieved”.

Although other companies may have the capacity to produce the numbers required, very few possess the capabilities, skillset and knowledge that would enable such a complex and large design, test, manufacturing and delivery campaign to be achieved in such a short time.

“Our customer is delighted!” Cairns elaborates. “We were able to deliver 80% of the order a week ahead of schedule, which gave it enough capacity to meet the OEM’s just-in-time delivery timescales. Although scenarios like this are not good for the heart rate, it is reassuring to our customers that we can merge our capacity with the skills and capabilities to make sure that rush orders – even ones as complex as this – have the same level of well-deserved quality that more timely orders enjoy. We threw everything at this order to ensure the customer’s goodwill, and we would do it again… just give us a chance to catch our breath first.”

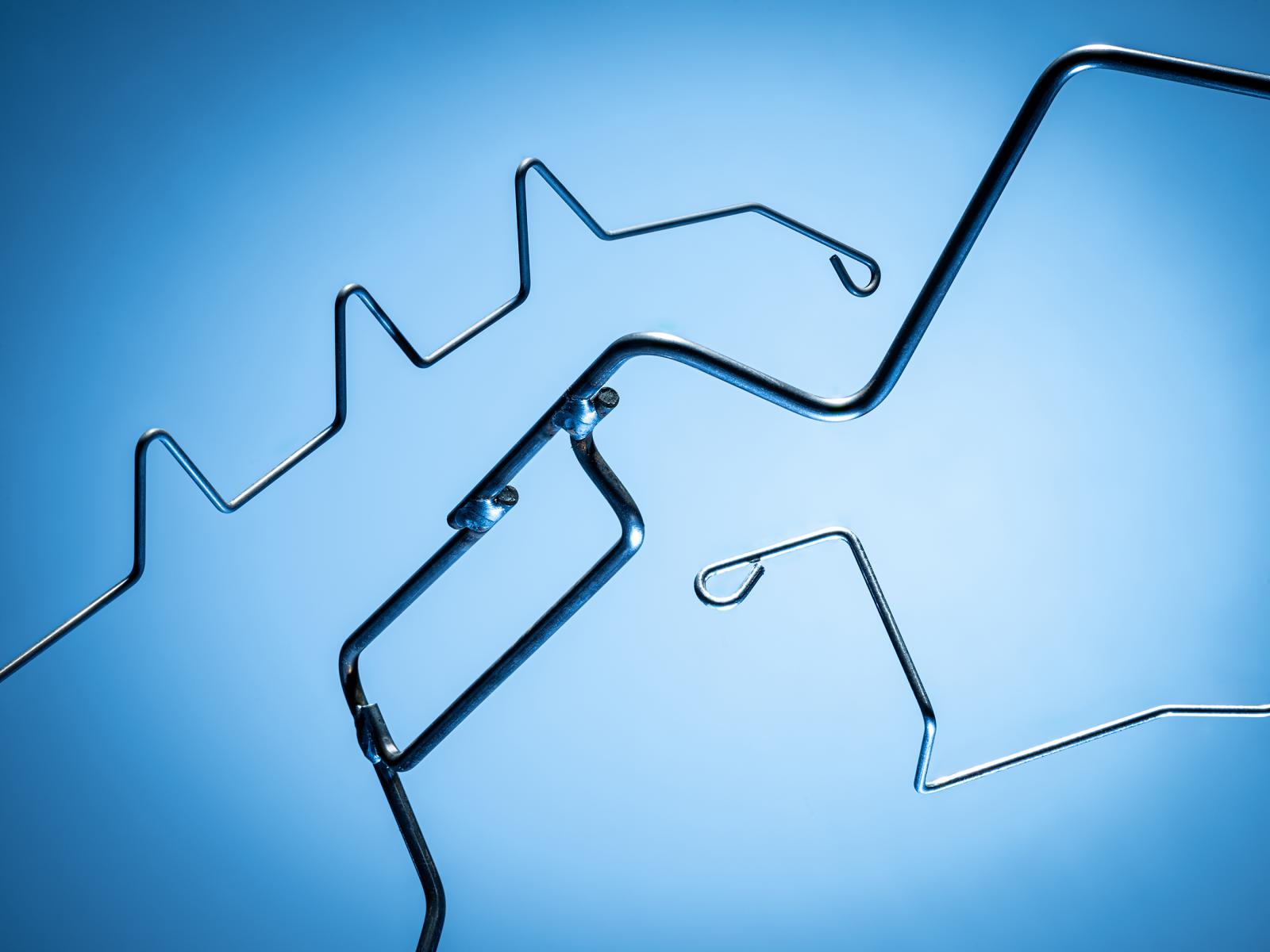

Photo: Some of the complex wire forms involved in William Hughes’ latest challenge