R-TECH Materials, a testing, analysis and consultancy businesses, is showcasing its capabilities at this year’s Advanced Engineering Show (AES 2017) at the NEC.

The company’s UKAS accredited state-of the-art laboratories run tests on all types of engineering materials from composites and polymers to metals and ceramics.

R-TECH’s team of engineers, metallurgists, materials scientists and chemists help manufacturers with material approval and characterisation; identify quality issues; solve processing problems or identify why a product has failed.

R-TECH has recently invested in a range of equipment including a chemical analyser for carbon sulfur and nitrogen; a laboratory bend machine for rebar; a deflectometer for flexural testing; and automatic polishing equipment for preparing micro sections and macro sections of welds. It also expects to secure aerospace approval from Nadcap later in 2017 and has teamed up with Zwick Roell to run training courses on mechanical testing of composites.

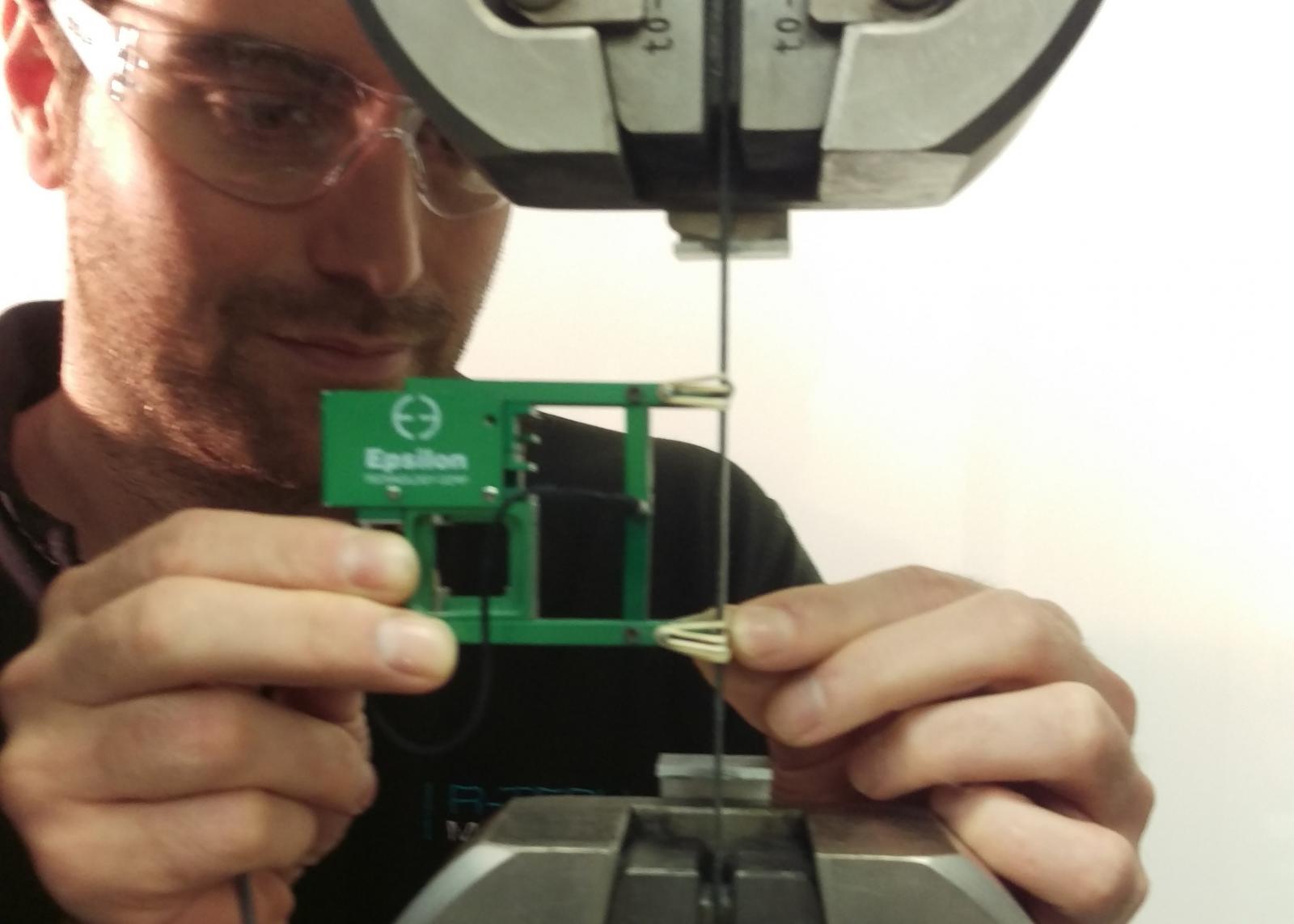

The company can test complex orientations to loads up to 1500kN. Standard tests include lap shear, in-plane shear, climbing drum peel, shore hardness, compression of core materials and shear properties of sandwich panels, as well as fatigue testing (in tension or in bending) at loads of up to 100kN. R-TECH can also offer its customers bespoke testing thanks to its biaxial extensometry with strain gauging capabilities.

Operating across a wide range of industries, including aerospace, marine and automotive, R-TECH is accredited to perform testing in tension, compression, flexure, shear and hardness to ISO and ASTM standards under controlled temperature and humidity conditions. The company can also prepare laminates where required.

Visit R-TECH Materials at AES 2017 at the NEC Stand M122 between 1-2 November 2017.