Ceratizit gave Cutting Edge Precision Engineering the tooling support it needed to produce large quantities of components to support ventilator and respiratory systems.

When the Huntingdon-based subcontractor won the work for one existing and one new customer, it was faced with the challenge of sourcing tooling. To meet that demand it turned to Ceratizit UK & Ireland who could guarantee delivery, technical support and pricing to make the job work.

While its day-to-day work is focussed on machining parts for the telecoms, special purpose machinery and industrial printing machine sectors, Cutting Edge Precision Engineering’s portfolio of three and five-axis machining centres proved ideal when contacted by Lungfish Dive Systems, a specialist manufacturer of closed-circuit diving equipment, who have diverted their efforts to equipment breathing support for Covid-19 patients, generating additional requirements, over and above the 10,000 each of two machined ventilator components they are currently producing for another customer.

“Key to the project was the specification of tooling as we were not allowed to use any existing cutting tools due to the traceability and quality requirements from our customers, with cross contamination of materials being a major concern,” says Stuart Dunklin, Managing Director, Cutting Edge Precision Engineering. “This meant we had to have everything brand new and quickly. We therefore took advantage of Ceratizit’s ventilator support offer which as well as giving us a significant help with cost, it also ensured we got Ceratizit’s advice that recommended the best tools for the work and, that these tools were delivered the next day before noon. Additionally, as we were working over the weekend on the project, they made sure that we had telephone access to get technical support and cutting data for those tools we were not familiar with. The service has been excellent throughout.”

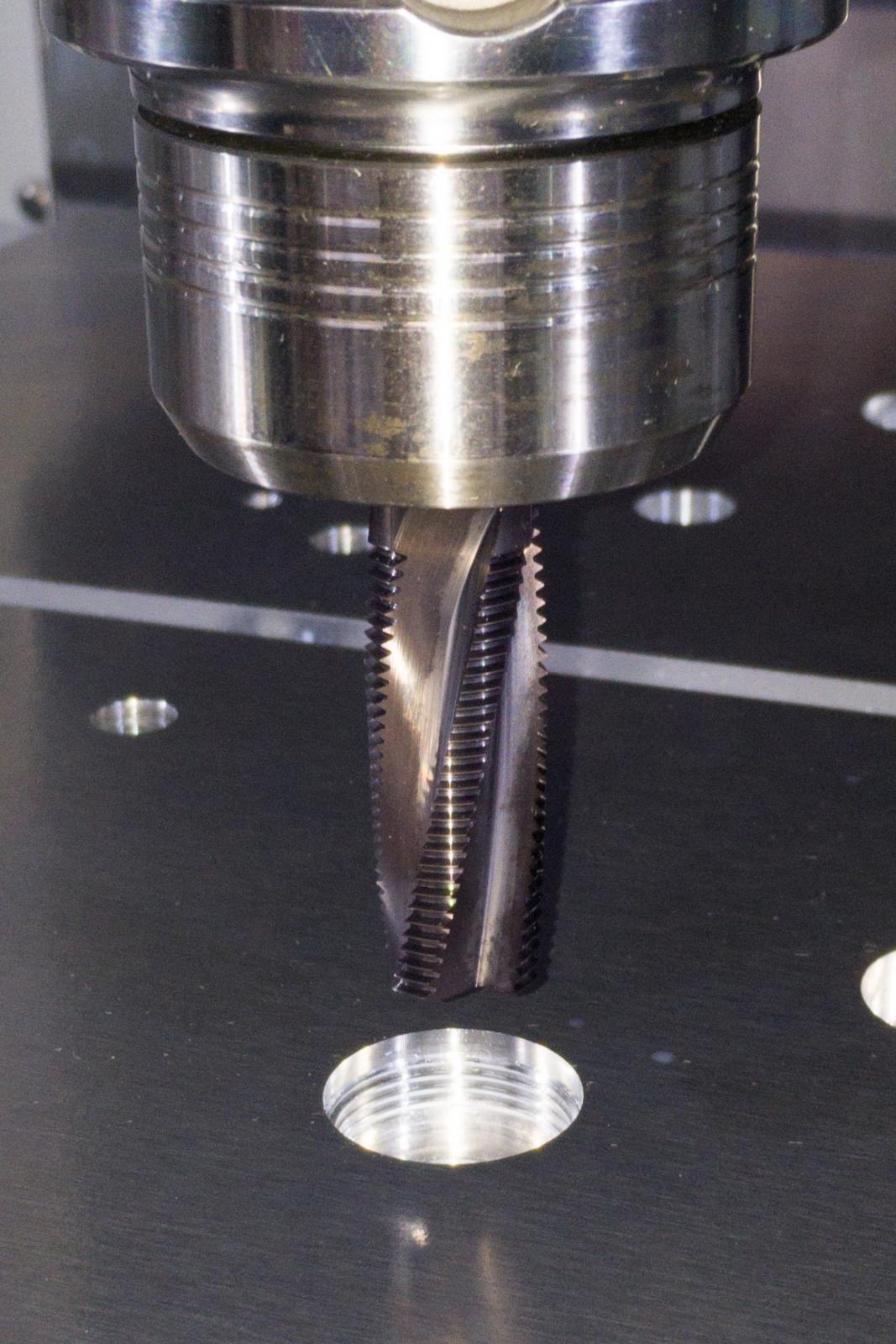

On this project alone Cutting Edge Precision committed five vertical machining centres, all of which required a range of Ceratizit cutting tools including end mills, drills, forming taps, threadmilling and drill-reamers for holes down to 5.02 mm diameter. In addition, a selection of workholding was also supplied. A further ventilator project is also coming to fruition, which will require the commitment of Cutting Edge Precision’s five-axis machining capability. This in turn will lead to demand for additional Ceratizit tooling and workholding, specifically vices and tombstone-style fixturing to be able to achieve the volumes required.

“The Ventilator initiative that we have in place has been extremely popular and has enabled customers like Cutting Edge Precision to step up in support of the Government’s call for additional resources to fight the Covid-19 pandemic. In my sales area alone I have 12 customers that have engaged with us to ensure they have the right tools at the right time to machine parts for these urgently required pieces of equipment,” says Warren Howard, Technical Sales Engineer, Ceratizit UK & Ireland.