A ‘Fast Make’ turbine specialist has uprated its toolroom capacity to support its manufacturing capabilities.

Rugby-based Raysun has developed its business from a designer and manufacturer of bespoke jigs and fixtures with a well-equipped toolroom facility to become one of the UK’s leading ‘Fast Make’ specialists for turbine components, with a particular emphasis on development of smaller hot gas parts such as nozzle guide vanes, seal segments, seal carriers and turbine blades for aerospace and land-based applications.

This involvement with the turbine industry came from Raysun’s early collaboration on the Rolls-Royce Viper Grinding project where both Tyrolit and Raysun engineers were heavily involved with Rolls-Royce in the invention, development and exploitation of the Viper technology.

Raysun’s involvement in the Viper Grinding project also opened up opportunities to further diversify the business, which saw the introduction of its ‘fast make’ concept that provides rapid product development of small hot gas turbine components. “Typically, it could take an OEM 12 - 18 months to take these parts from concept to production ready parts. With our systems and flexibility, we can achieve this in under six months. Typically, we spend 4-6 weeks on each stage of the project, with these being design; jigs and fixture production; and final product development, with machining work spread across our toolroom and separate production facility.” says Charles Ray. “The result of this fast make concept has been rapid growth over the past three years, and we have several active projects in-hand for major customers, which have placed additional pressure on the ageing machinery within the toolroom.”

A legacy of the work on Viper Grinding meant that virtually every machine at Raysun featured a Heidenhain control, and this would be the first tick box in selecting any replacement machine. The recently added option of the Heidenhain TNC 620 Control to the its HD range of vertical machining centres meant that XYZ Machine Tools were able to meet Raysun’s new machine requirements.

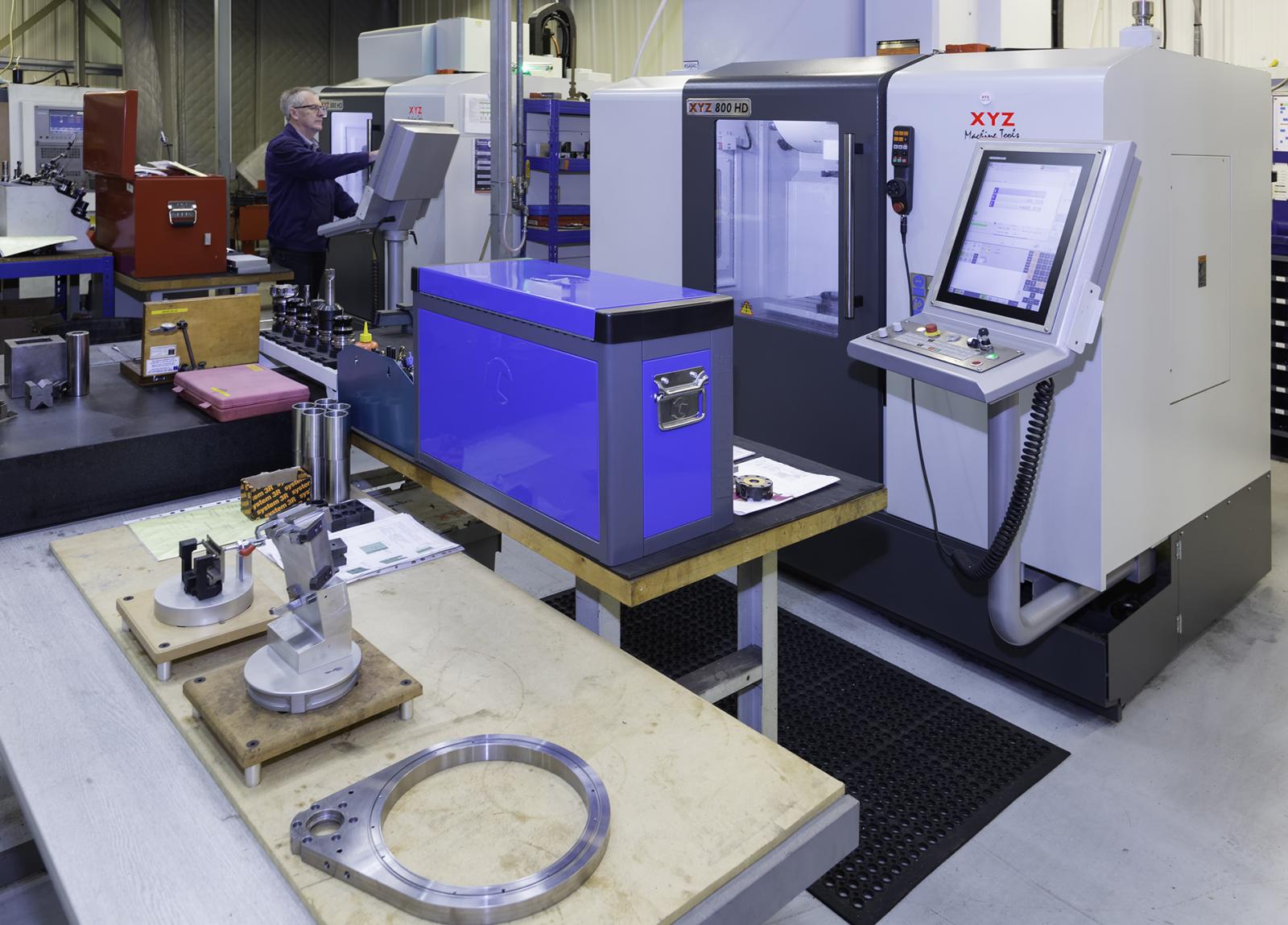

“Without the choice of the Heidenhain control, which we are very familiar with, we probably wouldn’t have even considered XYZ as an option, but when we saw it was available the other aspects of machine choice fell into place,” says Charles Ray. “The toolroom works on a wide range of parts some with small high precision features and other much larger items such as assembly jigs for building cars. To cover the range of requirements a machining centre with a reasonable size table was required and the XYZ 800 HD was ideal. The combination of the XYZ 800 HD machining centre and the Heidenhain control has definitely impressed us and it fitted our requirements well with the added benefit of being a price competitive package that was available in the time-frame that we had available.”

Raysun now has two XYZ 800 HD VMCs in place with their 800 x 500 x 510 mm axis travel and 920 x 480 mm table size with a 900 kg load capacity being fully employed in a variety of toolroom applications.

Raysun also needed to add to its turning capabilities and here it compromised on its desire for Heidenhain control and took delivery of an XYZ SLX355 ProTurn lathe with the SLX ProtoTRAK control. With milling, grinding and EDM being the key areas within the toolroom turning is an aspect of the business that has a lesser, yet vital, role to play and one where versatility is key. “The ProtoTRAK control is ideal for what we needed as it allows anyone to step up to the lathe and operate it thanks to its ease of use. As with the XZ 800 HD the size and capability met our requirements and it is a no-nonsense machine that does an excellent job day-today for us,” says Charles Ray.

With these three machines from XYZ Machine Tools in place, the Raysun Toolroom is better placed to deliver to the expectations of the ‘fast make’ side of the business as well as individual customers for its general toolroom services.

BACK TO ENGINEERING CAPACITY NEWS PAGE