Norsk Titanium will deliver the ‘world’s first’ FAA-Approved, 3D-printed structural titanium components to Boeing for its 787 Dreamliner.

This will make the Dreamliner the first commercial aircraft to fly with certified additive-manufactured structural titanium components.

Warren M Boley, Jr, president and CEO, Norsk Titanium, said: “The Norsk Titanium team will continue to expand the portfolio of components supplied to Boeing meeting stringent certification requirements. It is an honour to earn FAA approval for these structural parts.”

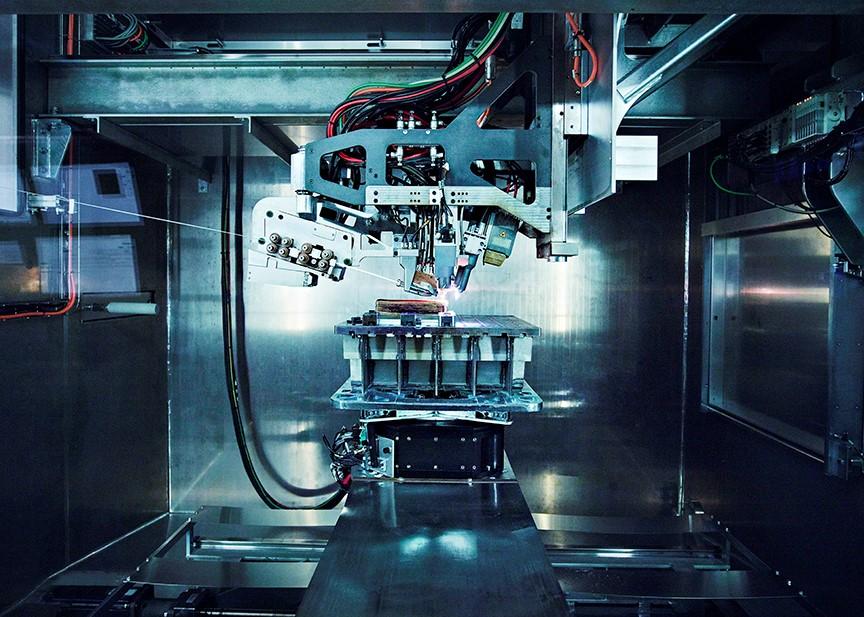

The parts will be produced by Norsk’s proprietary Rapid Plasma Deposition (RPD) process.

Boeing designed the components and collaborated closely with Norsk Titanium throughout the development process.

To certify these initial structural components on the Dreamliner, Boeing and Norsk Titanium undertook a rigorous testing programme with FAA certification deliverables completed in February 2017.

Norsk Titanium, with its wire-based RPD process, is the first supplier for Boeing’s high deposition rate material specification.

John Byrne, vice president, Airplane Materials and Structures, Supplier Management, Boeing Commercial Airplanes, said: “We are always looking at the latest technologies to drive cost reduction, performance and value to our customers and Norsk Titanium’s RPD capability fits the bill in a new and creative way.”

Norsk Titanium AS is a supplier of aerospace-grade, additive manufactured, structural titanium components. The company is known for its patented RPD process which transforms titanium wire into complex components suitable for structural and safety-critical applications.